Jan 05, 2026

In pneumatic systems, leakage is rarely caused by poor components alone. More often, it comes from mismatched threads, incorrect sealing methods, or misunderstanding how a thread is designed to work. Among the many thread standards used worldwide, NPT fitting remains one of the most commonly specified, especially in North America and in equipment exported globally. Understanding what an NPT fitting really is—and how it achieves sealing—can prevent long-term reliability issues in pneumatic and hydraulic installations.

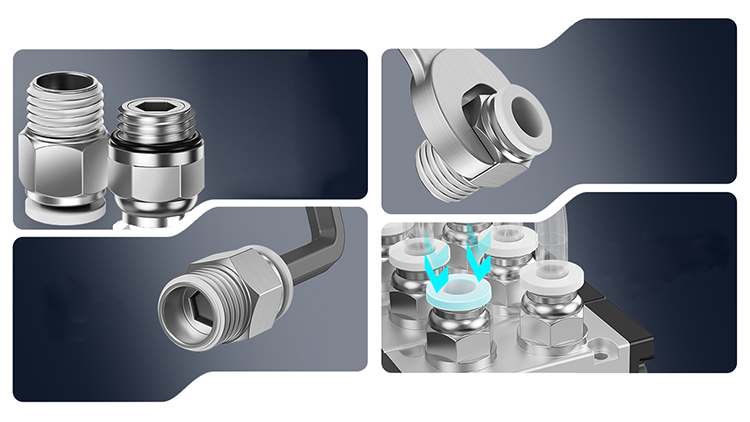

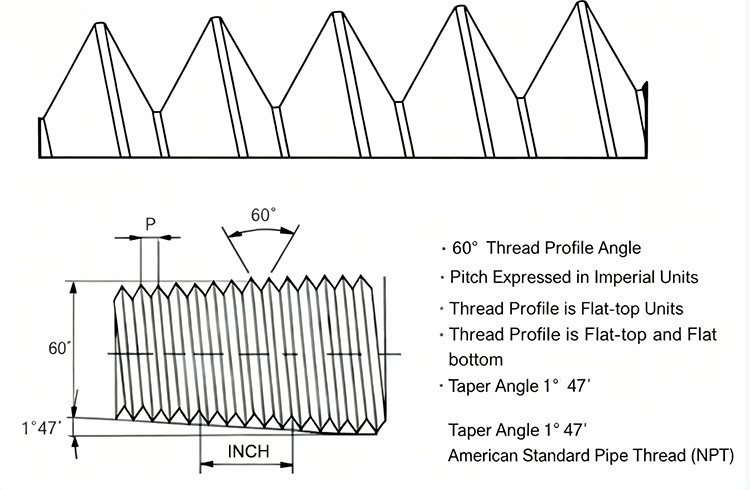

An NPT fitting refers to a connector using National Pipe Taper threads. Unlike straight threads that rely on O-rings or washers, NPT threads seal through a tapered mechanical interference. The thread profile uses a 60° thread angle, and the diameter gradually decreases along the thread length. As the fitting is tightened, the male and female threads wedge together, creating pressure at the flanks of the threads.

This design explains why NPT fittings are widely considered self-sealing. However, self-sealing does not mean sealant-free in real industrial environments. Vibration, pressure fluctuation, and thermal expansion all affect the contact surfaces, which is why professional installers rarely rely on metal-to-metal contact alone.

The tapered structure of NPT threads is not accidental. The 1 in 16 taper ratio ensures progressive tightening, allowing installers to “feel” when resistance increases. This characteristic is especially useful on factory floors, where fittings are often installed manually during assembly or maintenance.

Compared with parallel threads, the 60° tapered design offers two practical advantages. First, it tolerates small machining deviations without immediate leakage. Second, it allows reuse in maintenance scenarios where fittings may be removed and reinstalled. For distributors and equipment builders, this reduces warranty risks caused by minor installation errors.

That said, the same taper that enables sealing also introduces stress concentration. Over-tightening can crack aluminum manifolds or distort brass ports, a common failure mode observed in pneumatic control panels.

Although NPT fittings are often described as self-sealing, experienced engineers know that PTFE (Teflon) thread seal tape or liquid thread sealant is almost always used. The purpose is not to replace the mechanical seal, but to fill microscopic gaps between threads.

Without sealant, compressed air can escape through spiral leakage paths along the threads. This becomes more pronounced at higher pressures or when fittings are subject to vibration. PTFE tape acts as a deformable filler, improving sealing reliability while also reducing friction during tightening.

Best practice in pneumatic systems is to apply PTFE tape clockwise, 2–3 wraps, keeping the first thread free of tape to avoid contamination inside valves or cylinders. This simple step significantly improves long-term system stability.

NPT fittings are available in multiple materials, each suited to different operating environments. Material selection affects corrosion resistance, pressure rating, and compatibility with media.

| Material | Typical Use | Key Advantage |

|---|---|---|

| Brass | General pneumatics | Good corrosion resistance, easy installation |

| Stainless Steel (304/316) | Food, chemical, outdoor | High strength, excellent corrosion resistance |

| Carbon Steel | Hydraulic systems | High pressure capability |

| Engineering Plastics | Low-pressure air | Lightweight, cost-effective |

According to industrial fluid power market analyses, brass and stainless steel NPT fittings account for the majority of pneumatic installations due to their balance of durability and cost.

One of the most frequent causes of leakage is mixing NPT threads with similar-looking standards. NPT is often confused with BSPT or metric tapered threads, especially in international projects.

Key differences include thread angle and pitch. NPT uses a 60° angle, while BSPT uses 55°, making them incompatible even if they seem to screw together initially. This mismatch leads to uneven contact, damaged threads, and delayed leakage that may only appear after weeks of operation.

For equipment exporters and distributors, clarifying thread standards during procurement avoids costly after-sales support and reputation damage.

Despite the availability of newer sealing technologies, NPT fittings remain widely used across industries. Typical applications include:

◆Pneumatic cylinders and valve manifolds

◆Air preparation units (FRL systems)

◆Solenoid valves and angle seat valves

◆Hydraulic auxiliary lines

◆Compressed air distribution piping

In OEM equipment, NPT fittings are often selected for export models destined for North American markets, where compatibility and service familiarity are critical.

Even high-quality NPT fittings can fail if installed incorrectly. Experienced technicians follow a few simple rules that significantly extend service life.

First, avoid using excessive torque. The taper creates sealing pressure naturally; forcing the fitting only increases the risk of port damage. Second, ensure thread cleanliness before applying sealant. Metal chips or old PTFE residue compromise sealing effectiveness.

Finally, pressure testing after installation is not optional. Small leaks rarely stay small, especially in systems running continuously.

As a global pneumatic component supplier, FOKCA Automation provides a complete range of NPT fittings designed for industrial reliability. Our portfolio includes brass, stainless steel, and engineered alloy fittings compatible with pneumatic cylinders, solenoid valves, air control valves, and air preparation units.

Beyond standard products, FOKCA supports OEM/ODM customization, including special thread lengths, material upgrades, and combined metric-to-NPT transition fittings. This is particularly valuable for distributors serving mixed-standard markets or equipment manufacturers exporting globally.

Our fittings are produced with controlled thread tolerances and surface finishes to ensure consistent sealing performance when used with PTFE tape or approved liquid sealants.

I can help you choose the most suitable products for your application.

If you would like to learn more about pneumatic push-in fittings, pneumatic tubing, or other air-line components, please feel free to contact us at any time. FOKCA is committed to providing you with the most professional support and service.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap