Dec 23, 2025

In food and beverage production, pneumatic hoses are rarely noticed until something goes wrong—cloudy tubing, strange odors, microbial buildup, or unexpected cracking after months of use. For systems such as food pump dispensers, filling lines, or automated dosing equipment, material choice is not just a technical preference but a hygiene and lifecycle decision. This is why most food-grade polyurethane tubing on the market is ether-based rather than polyester-based.

Understanding this difference helps distributors recommend the right products, engineers design safer systems, and procurement teams avoid costly replacements.

Almost all food-related pneumatic applications involve water, steam, or frequent washdowns. From beverage bottling plants to dairy processing lines, hoses are constantly exposed to moisture—sometimes hot, sometimes chemically treated.

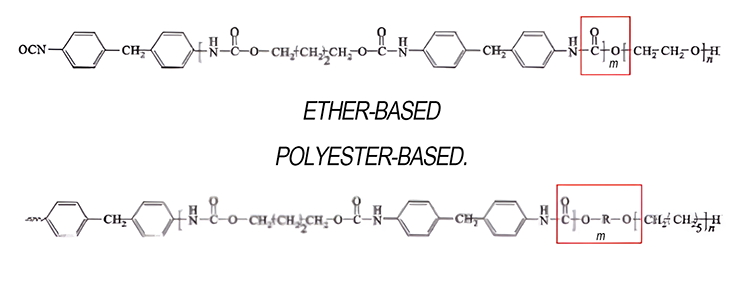

Polyester-based polyurethane contains ester bonds that are chemically vulnerable to hydrolysis. Under continuous exposure to water or humidity, these bonds gradually break down. The result is a hose that becomes brittle, discolored, and structurally weak over time. In a pneumatic hot hose environment, this degradation accelerates dramatically.

By contrast, ether-based polyurethane tubing is built around ether linkages, which are inherently resistant to hydrolysis. Even after long-term exposure to moisture or cleaning cycles, the material maintains its mechanical integrity. This hydrolysis resistance is the primary reason ether-based PU has become the standard for PU hose food grade applications.

From a hygiene perspective, material degradation is more than a durability issue—it’s a contamination risk. As polyester-based hoses hydrolyze, microscopic cracks and surface roughness develop. These imperfections create ideal conditions for bacteria and biofilm to form, which is unacceptable in food processing.

Ether-based materials offer better resistance to microbial attack, helping maintain a smoother internal surface over time. This is particularly important in systems like food pump dispensers or low-pressure food grade air hose lines, where air quality directly impacts product safety.

In practical terms, an ether-based polyurethane hose often lasts 2–3 times longer than a polyester alternative in wet food environments, according to multiple industry lifecycle analyses. Longer service life means fewer changeovers, lower maintenance costs, and reduced production downtime.

Many food facilities operate in cold or fluctuating temperatures—cold storage rooms, refrigerated conveyors, or outdoor beverage lines. Polyester-based PU tends to stiffen significantly at low temperatures, increasing the risk of kinking or cracking during movement.

Ether-based polyurethane retains excellent low-temperature elasticity, often remaining flexible well below freezing. For pneumatic hose management systems that involve constant motion, bending, or routing through tight spaces, this flexibility is a major operational advantage.

This is also why ether-based formulations are commonly used not only in polyurethane hose food safe designs, but also in related materials such as polyurethane ether foam used for seals and cushioning in food equipment.

Food-grade hoses are routinely exposed to cleaning chemicals—alkaline detergents, mild acids, and sanitizing agents. Polyester-based polyurethane shows limited resistance to prolonged chemical exposure, especially when combined with heat and moisture.

Ether-based PU performs more consistently under these conditions. While no polymer is completely immune, ether-based food grade polyurethane tubing shows slower property degradation, helping hoses maintain transparency, flexibility, and pressure stability after repeated CIP (Clean-in-Place) cycles.

For procurement managers, this chemical stability translates into predictable replacement intervals and easier compliance with internal hygiene audits.

It’s important to be transparent: ether-based polyurethane is not the best choice for oil-heavy environments. Polyester-based PU generally offers superior resistance to oils, fuels, and hydrocarbons.

However, in food and beverage systems, oil exposure is typically minimal or tightly controlled. The design priority shifts toward water resistance, hygiene, and durability. That’s why ether based polyurethane hose food safe products dominate this sector, while polyester-based PU is more commonly found in industrial oil or automotive pneumatic applications.

Understanding this distinction allows distributors and engineers to avoid mismatched recommendations that look good on paper but fail in real operating conditions.

At first glance, polyester-based and ether-based polyurethane hoses may look similar. The real difference only appears months later, under water exposure, cleaning cycles, and continuous operation. In food applications, that difference can determine whether a system runs reliably—or becomes a hygiene liability.

For food grade air hose systems, the question is not which material is cheaper, but which material stays safe, stable, and compliant over time. That is why ether-based polyurethane remains the preferred choice across food processing, beverage dispensing, and packaging industries.

If you are designing, distributing, or sourcing pu hose food grade solutions, understanding this material distinction is not optional—it is essential for protecting both your equipment and your reputation.

As a global supplier of pneumatic components, FOKCA Automation works closely with distributors, equipment manufacturers, and end users to match materials with real-world operating conditions. Our ether-based PU food grade hoses are designed for environments where moisture, hygiene, and reliability matter more than short-term cost savings.

In addition to tubing, FOKCA provides a complete ecosystem—standard and customized cylinders, valves, fittings, and pneumatic hoses—allowing customers to source compatible components from a single, technically aligned supplier. OEM and ODM support ensures that hose specifications can be adapted for pressure, temperature, and routing requirements without compromising food safety expectations.

For more detail you can contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap