Dec 18, 2025

Fluoropolymers are known for their exceptional chemical resistance, high-temperature stability, and overall durability. Among them, PTFE and PFA are two widely used materials in industrial applications. Both come at a premium price due to their superior properties, but they serve slightly different purposes. Understanding the differences between PTFE and PFA is essential for engineers, procurement managers, distributors, and end-users to select the right material for their applications.

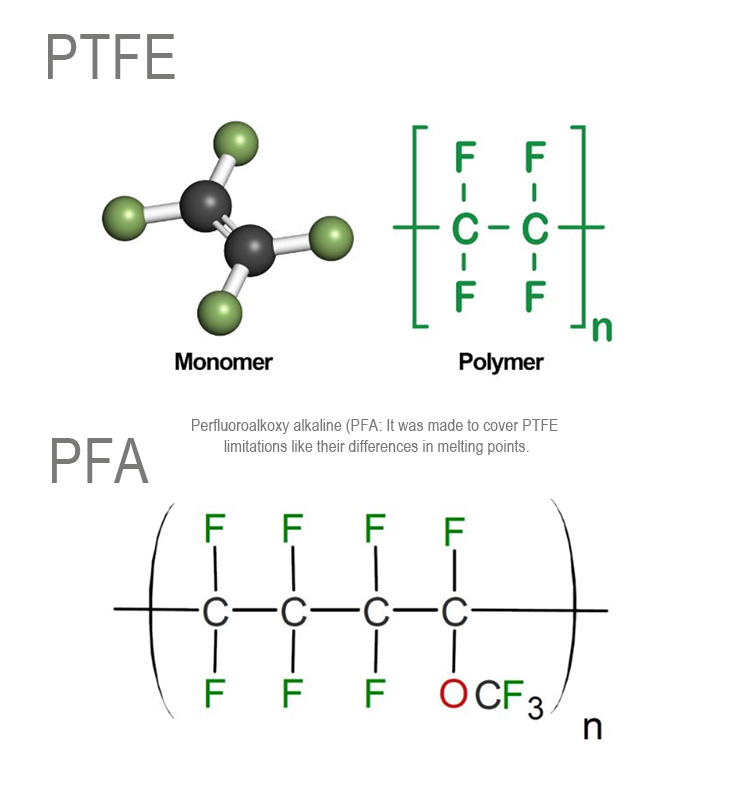

PTFE, originally developed by DuPont in the United States, is widely recognized under the trade name Teflon. Its outstanding chemical resistance, extremely low coefficient of friction, and wide temperature range (-200°C to 260°C) have made it a standard in chemical processing, food, and pharmaceutical industries.

However, PTFE has some inherent limitations: its mechanical properties are relatively weak, making it prone to creep under stress. Additionally, its poor processability and opacity can be limiting factors in certain applications. For instance, machining PTFE into complex shapes or creating transparent tubing is challenging.

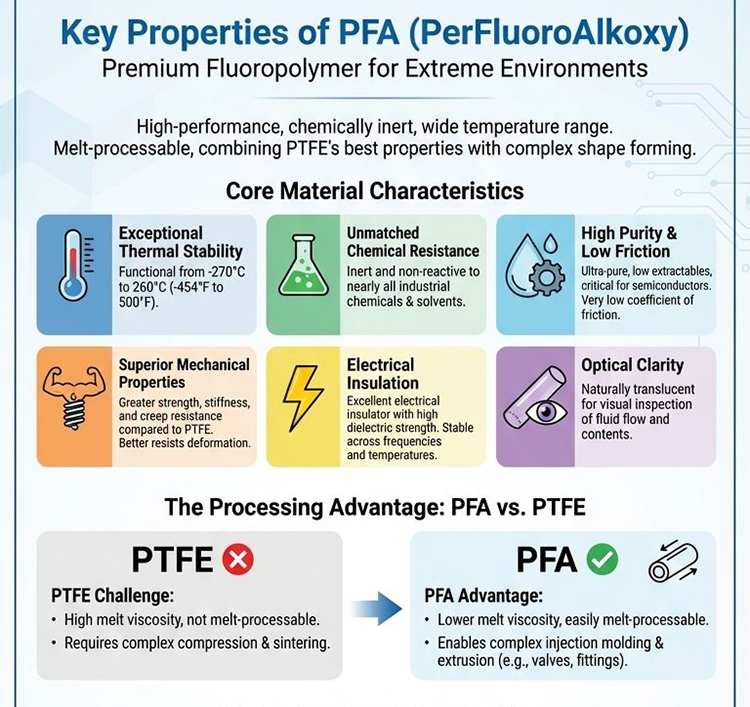

PFA , developed after PTFE, addresses many of PTFE's shortcomings. While maintaining excellent chemical resistance and high-temperature stability, PFA surpasses PTFE in several key aspects:

1.Mechanical Strength: Higher tensile strength reduces creep under stress

2.Processability: Easier to mold, extrude, and fabricate into complex shapes

3.Transparency: Clearer material allows visual monitoring of fluids

Because of these advantages, PFA Tubings is widely used in applications where PTFE may fail, including high-precision fluid transfer, cleanroom pneumatic systems, and chemical dosing lines. Naturally, these performance benefits come at a higher price.

Property | PTFE (Teflon) | PFA |

Chemical Resistance | Excellent | Excellent |

Temperature Range | -200°C to 260°C | -200°C to 260°C |

Mechanical Strength | Moderate | High |

Processability | Difficult | Easy |

Transparency | Opaque | Transparent |

Typical Applications | Gaskets, seals, linings | Tubing, hoses, custom parts |

This table highlights why PFA is often chosen over PTFE when mechanical strength, ease of fabrication, or transparency is required, despite its higher cost.

Both PTFE and PFA are used in industries that demand high chemical resistance and thermal stability:

1.Chemical Processing: Both materials handle corrosive chemicals without degradation

2.Pharmaceutical & Food Industries: Non-reactive, safe for fluid contact

3.Semiconductor & Cleanroom Systems: PFA preferred for transparency and precise tubing fabrication

4.Industrial Automation: PFA pneumatic hoses and tubing allow flexible, reliable operation under stress

For engineers and distributors, knowing which material to select can prevent equipment failure and optimize system efficiency.

When deciding between PTFE vs PFA, consider the following factors:

◆Mechanical requirements: PFA offers better tensile strength and creep resistance

◆Fabrication needs: PTFE is difficult to mold, whereas PFA can be extruded or injection-molded

◆Visual inspection: PFA's transparency allows fluid observation, PTFE does not

◆Budget constraints: PTFE is generally less expensive, but PFA may reduce maintenance and downtime costs

A careful evaluation ensures optimal performance, especially in high-purity, corrosive, or precision fluid systems.

FOKCA Automation offers a comprehensive range of PTFE and PFA components, including pneumatic hoses, tubing, fittings, and custom parts. Key advantages include:

◆OEM/ODM Customization: Flexible diameters, lengths, and shapes tailored to specific industrial needs

◆Quality and Consistency: High-quality fluoropolymer material ensures predictable performance across batches

◆Technical Support: Expert guidance for material selection, installation, and maintenance

◆Versatile Applications: Suitable for chemical, pharmaceutical, semiconductor, and automation systems

By combining PTFE or PFA materials with FOKCA’s precision manufacturing, clients can achieve reliable, long-lasting system performance.

While PTFE (Teflon) laid the foundation for high-performance fluoropolymers,PFA has emerged as the advanced solution for applications requiring higher mechanical strength, processability, and transparency. Both materials have their place, and selecting the right one depends on system requirements, fabrication needs, and budget considerations. FOKCA Automation provides tailored PTFE and PFA solutions that meet rigorous industrial standards, offering distributors, engineers, and end-users reliable, high-performance components for demanding environments.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap