Dec 10, 2025

Nickel-plated brass fittings have become a top choice across pneumatic, hydraulic, and industrial fluid systems. Their excellent durability, clean appearance, and resistance to corrosion make them superior to standard brass components in demanding environments. Whether you are a distributor, equipment engineer, purchasing manager, or factory owner, understanding the advantages of nickel plating on brass fittings can help you select products that last longer, perform better, and enhance the overall reliability of your equipment.

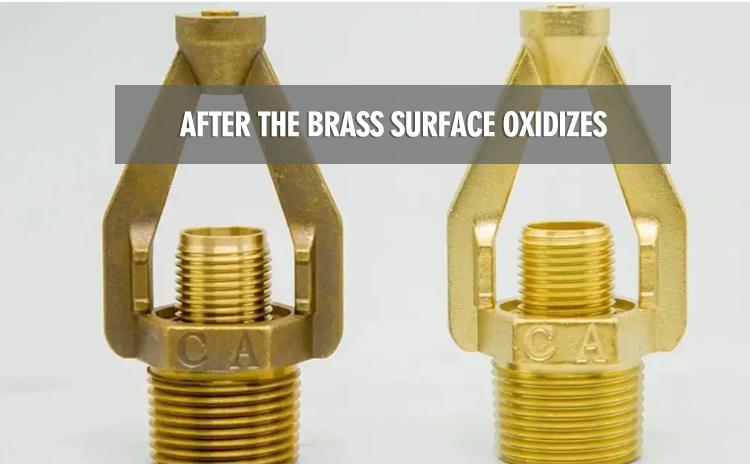

Raw brass tends to oxidize when exposed to moisture, oil mist, or ambient air. This oxidation forms dark, brownish stains that—not only affect appearance—can also hinder smooth installation and long-term sealing performance.

Nickel plating creates a dense, protective barrier between the brass substrate and the environment. This prevents:

1.air and moisture from reacting with copper

2.surface discoloration

3.build-up of oxide particles in sealing areas

In workshops with high humidity or oil mist near compressors, nickel-plated brass fittings maintain a clean, stable surface far longer than uncoated brass. The result? Better sealing, easier disassembly, and longer service life.

Distributors also benefit from products that maintain a “new” appearance during warehousing and shipping.

FOKCA ensures consistent plating thickness to deliver strong, uniform protection across every fitting.

One of the biggest advantages of nickel plating is the significant improvement in surface hardness. A nickel-plated layer acts like a protective shell, increasing surface hardness to approximately 150–300 HV, depending on the plating process.

This higher hardness provides key performance benefits:

◆ enhanced resistance to scratches and abrasion

◆ reduced thread deformation during tightening

◆ improved durability in equipment subjected to continuous vibration

◆ extended service life of sealing and connection surfaces

In industries such as woodworking, packaging, or textile machinery where micro-vibrations are constant, engineers report that nickel-plated brass fittings remain stable for years—while non-coated brass often shows thread wear after just a few months.

Beyond mechanical performance, appearance plays a critical role for OEM manufacturers. Nickel-plated fittings offer a clean, silver metallic finish that pairs perfectly with:

◆ aluminum manifolds

◆ stainless steel cylinders

◆ pneumatic valves

◆ clear PU or nylon tubing

For automation systems, robot units, display equipment, and high-end machines, a consistent visual aesthetic helps build customer confidence and enhances perceived build quality.

FOKCA also supports OEM customers by offering custom brightness levels and uniform plating tone, ensuring all fittings across a machine present a cohesive professional look.

Nickel plating significantly improves the chemical stability of brass, making fittings more resistant to:

◆ oil mist

◆mild acids or cleaning agents

◆machining fluids

◆dust and metal particles

◆moisture and humidity

This makes nickel-plated brass fittings suitable for a wider range of industrial applications, including:

◆CNC machining automation

◆metal processing lines

◆woodworking equipment

◆packaging machines using adhesives

◆compressor environments with high oil content

Because of this increased adaptability, purchasing teams can often standardize on nickel-plated brass fittings across multiple machine models, reducing inventory complexity.

PU (polyurethane) and PA (nylon) tubes require a smooth, stable sealing surface. Oxidized brass can develop micro-particles that damage tubing or cause leaks over time.

Nickel-plated brass fittings provide:

1.long-term smooth surface finish

2.reduced tube wear

3.consistent sealing performance

4.cleaner engagement in quick-connect and rapid pneumatic fittings

For rapid pneumatic fittings—especially those that are frequently reconnected—nickel plating ensures the nut, gripping claws, and sealing surfaces operate smoothly without generating metal dust.

Many equipment engineers prefer nickel-plated fittings because they help prevent unplanned downtime caused by air leaks or deteriorated tubing.

Although nickel plating adds a manufacturing step, it significantly reduces overall lifetime cost by improving durability and lowering maintenance frequency.

Cost-saving benefits include:

◆longer shelf life without discoloration

◆reduced warranty claims

◆fewer issues caused by installation damage

◆lower maintenance cost for end users

◆the ability to standardize across multiple environments

FOKCA specializes in precision-engineered brass fittings and industrial-grade nickel plating. Each fitting is CNC-machined for consistent tolerances, and every plating batch undergoes multi-stage testing to ensure durability, adhesion, and corrosion resistance.

Key advantages of FOKCA’s nickel-plated fittings:

◆industrial-grade nickel plating for enhanced corrosion resistance

◆CNC machining for reliable thread consistency

◆compatibility with complete pneumatic systems

◆strong OEM/ODM support for global distributors

◆tested performance under vibration, pressure cycling, and long-term use

FOKCA fittings can be paired with our cylinders, valves, FRL units, and rapid pneumatic fittings to build complete, high-quality pneumatic systems.

For more information or to place an order, feel free to contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap