Dec 09, 2025

When engineers compare different flexible hoses , the word “flexibility” is always mentioned. Hardness has standardized testing methods and numerical values, yet flexibility is often treated as a vague feeling. In practice, flexibility is made up of several measurable indicators, and the most intuitive one is the minimum bending radius. Understanding this value helps distributors evaluate product offerings, helps engineers design reliable equipment, and helps procurement managers select hoses that maintain durability over time.

Many users judge flexibility simply by hand-bending a tube and comparing which one feels softer. This subjective method often leads to inconsistent conclusions.

The bending radius gives a more concrete view of how a flexible hose behaves under curvature.

It refers to the smallest arc the tube can achieve without causing internal damage such as kinking, wall collapse, or long-term fatigue.

Once a tube is forced beyond this radius, the inner layers experience concentrated stress. This can lead to micro-cracks or dimensional distortion, especially in pneumatic systems where airflow stability is crucial.

Because of this, most technical datasheets specify a bending radius measured at 20°C, ensuring comparability across suppliers.

The minimum bend radius affects far more than installation convenience. Equipment engineers responsible for motion systems know that a tube with insufficient bending endurance will age prematurely.

In robotic arms, for example, a tube with a generous allowable radius ensures repeatability without fatigue hardening.

Distributors or dealers often observe that customers return hoses prematurely because they “became stiff after a few months.”

This usually happens when installation space forces the tube into a radius smaller than its specification. Procurement teams therefore insist on quantitative comparisons, not descriptions like “super flexible,” because only data like 20–40 mm bend radius allows reliable planning.

FOKCA integrates these parameters in itspneumatic tubing and quick-coupling lines, making it easier for engineers to match tubes with cylinders, valves, and actuators without unexpected service issues.

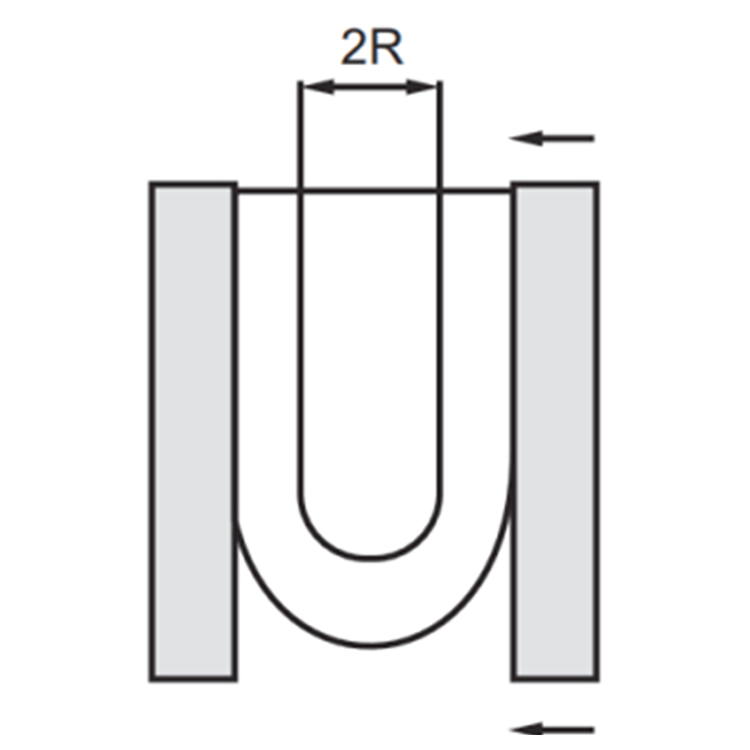

The simplified method used in most factories works surprisingly well when executed carefully. At 20°C, place the tube on a flat surface and gradually form it into a U-shape without applying abnormal force.

The test ends when the inner arc reaches the critical point before deformation begins.

Measurement Method

(Condition: Standard temperature 20°C)

Take a sample of the flexible tube, ideally at least 30 cm long.

Hold both ends with even force and curve the tube slowly.

Observe the internal wall—once the tube begins to flatten or wrinkle, stop bending.

Use a ruler to measure the distance D between the two ends.

Compute the bending radius using:

Bending Radius R = D / 2

Repeat the process 2–3 times for consistency.

Example of Test Result Table

Tube Type | Outer Diameter | Measured Distance (D) | Minimum Bending Radius (R) | Notes |

PU Flexible Hose | 8 mm | 70 mm | 35 mm | No visible collapse |

Nylon Tube | 8 mm | 95 mm | 47.5 mm | Slight stiffening |

PTFE Tube | 8 mm | 120 mm | 60 mm | Best at high temp |

(Data based on typical market ranges; varies by material grade and reinforcement structure.)

This method provides a quick evaluation for engineers and distributors without requiring laboratory instruments.

For precision-critical applications, manufacturers use mandrel-based bending tests following ISO pneumatic standards, which confirm long-term fatigue resistance.

A tube’s bending radius reflects the combination of its hardness, molecular structure, wall thickness, and processing method.

For instance, PU flexible hose is well-known for achieving small radii because of its high elasticity and recovery capability. Nylon has better pressure strength but becomes stiffer in colder zones, increasing its radius.

PTFE remains dimensionally stable under heat, but its structure resists sharp bends.

FOKCA’s OEM/ODM engineering team adjusts internal diameter, tolerance control, and extrusion parameters to optimize bending behavior based on different industrial needs.

For automation customers who require tighter installation spaces, FOKCA can customize thin-wall or hybrid-material hoses that achieve 20–25% smaller bending radius compared to standard market designs.

When selecting hoses for cylinders, solenoid valves, or actuators, engineers must match the bending radius to expected routing paths. If a flexible tube operates close to its minimum radius every day, internal stress accumulates.

Airflow turbulence increases, causing slower cylinder response. In packaging or textile machines that cycle thousands of times per day, this is often the hidden cause behind phenomenon like “cylinder speed becomes inconsistent after three months.”

A well-matched hose not only improves efficiency but also simplifies maintenance. FOKCA’s pneumatic cylinders and valves are designed so that recommended hose radii align with their port layout, reducing installation complexity for distributors and integrators.

Different industries require different bend behaviors. In robot welding systems, a tight bending radius prevents cable loops from interfering with movement. In textile or electronics assembly lines, soft polyurethane tubing keeps machines compact while ensuring a smooth flow.

For food processing environments, stainless-steel braided tubes or PTFE tubes may be selected even if the bending radius is slightly larger, because chemical resistance becomes the priority.

FOKCA supports OEM/ODM customization for all these scenarios, including modifications like:

Extra-long tubes for automated logistics systems

Ultra-soft micro-tubes for precision dosing equipment

Heat-resistant PTFE for high-temperature valves

Stainless-steel flexible tubes for corrosive areas

Customizable bending radius, color coding, and fittings help dealers expand their catalog with reliable products tailored to niche applications.

Understanding the minimum bending radius transforms flexibility from a vague description into a measurable engineering parameter. It enables accurate comparison between flexible hoses, reduces installation risk,

and ensures long-term reliability of pneumatic machines. For distributors and procurement teams, the bending radius becomes a powerful way to differentiate professional-grade hoses from generic products.

FOKCA supports global OEM/ODM partners with custom bending radius designs, ISO-aligned quality control, and a full range of related components including cylinders, valves, fittings, and quick couplers.

This unified ecosystem makes it easier for dealers and engineers to develop consistent, professional pneumatic systems.

If you would like to learn more about push-in fittings or pneumatic hoses , feel free to contact us . FOKCA will provide you with the most professional service.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap