Dec 16, 2025

In modern pneumatic systems, efficiency, safety, and reliability are crucial. Pneumatic quick couplings—also known as air hose quick connect, hose quick connection, or hose quick connect fittings—play a vital role in achieving these goals. They allow rapid assembly and disassembly of hoses and components, reducing maintenance time and ensuring leak-free connections. For distributors, engineers, and procurement managers, understanding these components is key to optimizing system performance and reliability.

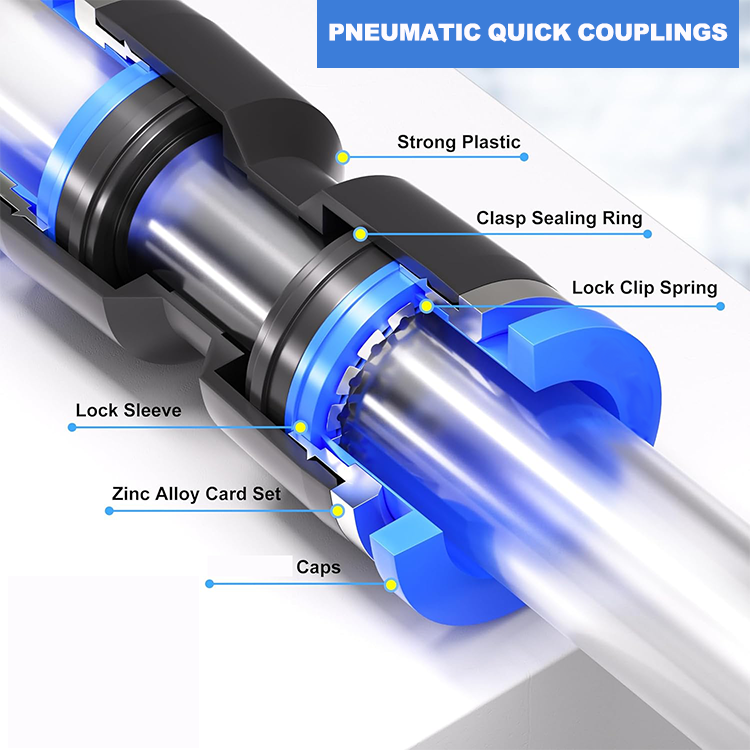

A pneumatic quick coupling is a device that connects air hoses to tools, valves, or equipment without the need for tools. The main advantage lies in its ability to quickly engage and disengage connections while maintaining a secure, leak-free seal. Unlike traditional threaded fittings, quick couplings save time, minimize errors during installation, and reduce system downtime.

Key benefits of pneumatic quick couplings include:

◆Time-saving: Rapid connection and disconnection of hoses and components.

Pneumatic quick couplings come in a variety of types, each suited for different applications. The most common include:

Allow instant connection of tubing by simply pushing it into the fitting.

Ideal for low to medium-pressure applications.

Easy disassembly with a release collar.

Secure connection using male and female threads.

Suitable for high-pressure applications.

Often used in industrial machinery and automotive lines.

Standardized connectors popular in pneumatic automation.

Compatible with a wide range of hoses and pneumatic devices.

Feature a mechanical lock to prevent accidental disconnection.

Common in safety-critical applications such as brakes or pressurized lines.

Comparison Table – Quick Coupling Types

Type | Pressure Rating | Ease of Use | Typical Applications |

Push-to-Connect | Low-Medium | Very Easy | General automation, assembly lines |

Threaded | High | Moderate | Industrial machinery, high-pressure |

SMC-Style | Medium | Easy | Robotics, automation systems |

Locking | Medium-High | Moderate | Safety-critical lines, pneumatics |

Pneumatic quick couplings are widely used in various industries due to their versatility:

Essential for assembly line air tools, brake system components, and fluid lines.

Push-to-connect couplings reduce assembly time and improve maintenance efficiency.

Used in pneumatic cylinders, robotic arms, and packaging equipment.

Quick couplings allow fast replacement of hoses without system shutdown.

Protect sensitive equipment by providing quick, leak-free air supply.

Example: PA66 or nylon tubing connected with quick couplings ensures consistent air pressure for testing or assembly lines.

A manufacturing plant using push-to-connect fittings reduced downtime during maintenance by 40%, enhancing productivity and saving costs.

The advantages of incorporating pneumatic quick couplings into systems extend beyond convenience:

Eliminates the need for wrenches or tools.

Supports frequent maintenance or reconfiguration of pneumatic lines.

High-quality seals ensure minimal air loss.

Contributes to energy efficiency and reduced operating costs.

Prevents accidental disconnections under pressure.

Reduces exposure to compressed air hazards.

Streamlines hose replacement and system modifications.

Allows engineers and technicians to perform work faster and with fewer errors.

Threaded vs Push-to-Connect Fittings Comparison

Feature | Threaded Fittings | Push-to-Connect Fittings |

Installation Time | Long | Very Short |

Leak Potential | Low | Very Low |

Maintenance Requirement | Moderate | Minimal |

Tool Requirement | Yes | No |

Choosing the correct pneumatic quick coupling depends on several factors:

1.Hose Diameter: Ensure compatibility with tubing.

2.Pressure Rating: Match system requirements.

3.Medium: Air, water, or inert gases.

4.Temperature Range: Consider environment conditions.

5.Material: Brass, stainless steel, or nylon/PA66 for durability and corrosion resistance.

FOKCA Automation Co., Ltd. is a global supplier of pneumatic and hydraulic components, offering high-quality pneumatic quick couplings and related products.

1.OEM/ODM Flexibility: Standard and custom solutions for any industrial need.

2.Comprehensive Product Range: Quick couplings, hoses, fittings, pneumatic components.

3.Durability and Quality Control: Leak-free, wear-resistant, and long-lasting.

4.Industry Support: Automotive, industrial machinery, electronics, and more.

Partnering with FOKCA ensures distributors, engineers, and procurement managers receive reliable, high-performance quick couplings, reducing maintenance costs and downtime while maximizing efficiency.

For more information on Quick couplings polyolefin tubings, please do not hesitate to Contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap