Jan 04, 2026

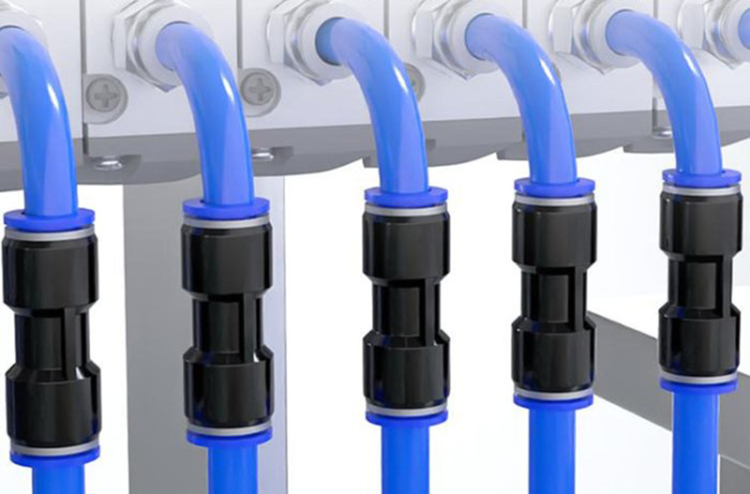

In pneumatic systems, air leakage is rarely caused by “bad fittings.” Much more often, it comes from a mismatch between tube material, tube hardness, and fitting type. In workshops and factories, it’s common to see PU tubing forced into compression fittings, or metal pipes awkwardly paired with push-in connectors—both choices quietly reducing system efficiency. Understanding how Pneumatic Fitting designs interact with different tubes is a practical skill that saves downtime, air loss, and long-term maintenance cost.

When engineers select fittings, diameter and thread size are usually checked first. Tube material and hardness are often an afterthought. Yet the sealing principle of a fitting—whether it relies on elastic deformation or mechanical compression—is directly tied to tube properties. Soft and semi-rigid tubes can deform to seal, while hard tubes require controlled compression or permanent joining. Ignoring this relationship leads to fittings that feel “tight” during installation but fail under pressure or vibration.

PU (polyurethane) and PA (nylon) tubes are widely used in automation because they balance flexibility, pressure resistance, and ease of routing. Their moderate hardness allows the tube wall to slightly deform under the grip of stainless steel claws and sealing O-rings. This is exactly how a Pneumatic Push In Fitting is designed to work. When inserted correctly, the tube forms an airtight seal without tools, making installation fast and repeatable on production lines.

In applications where maintenance speed matters—packaging machines, pick-and-place units, or modular automation—Pneumatic Quick Coupling solutions further simplify tube changes. The key is that PU and PA tubes recover their shape after insertion and removal, maintaining sealing integrity over multiple cycles.

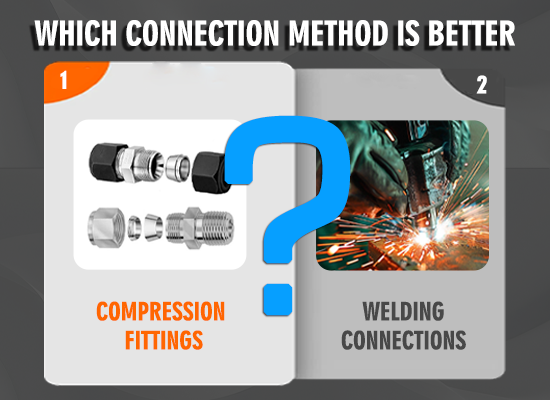

Compression (ferrule) fittings rely on rigid mechanical force. A metal ferrule bites into the tube surface to create a seal. This works well for hard materials, but with soft tubes, the result is unpredictable. The ferrule may cut into or ovalize the tube, causing uneven sealing. At first, the joint may appear leak-free, but pressure fluctuations or temperature changes often expose micro-gaps.

This is why using compression fittings on PU tubing often leads to intermittent air leaks—a nightmare for troubleshooting. For distributors and OEMs, recommending the correct Pneumatic Push In Fitting avoids these hidden failures and improves customer satisfaction.

Stainless steel, copper, aluminum, and hard plastic tubes (such as rigid PA or PTFE) cannot deform enough to seal inside push-in fittings. The gripping claws may scratch the surface, but the O-ring cannot compensate for the lack of elasticity. This is why push-in fittings on metal tubes almost always leak, even if they feel mechanically secure.

Compression fittings solve this problem by design. The ferrule creates a controlled, permanent deformation between the tube and fitting body, forming a high-pressure seal. For pneumatic panels, air distribution manifolds, and fixed pipelines, compression fittings provide long-term stability under vibration and thermal cycling.

Some metal fittings—especially brass or copper types—are designed for welding or brazing. These are common in high-temperature or permanent installations where threaded joints are undesirable. For example, copper welding fittings are typically used with copper pipes in fixed pneumatic or fluid systems.

These fittings are not interchangeable with push-in or compression types. They require skilled installation and are intended for metal-to-metal permanent connections only. Attempting to adapt soft tubing to welded fittings is not only impractical but unsafe.

In real-world projects, mismatches happen for cost or availability reasons. A procurement manager may substitute fittings without understanding tube behavior, or a technician may reuse parts from stock. Typical outcomes include:

1.Soft tube + compression fitting → tube damage, delayed leakage

2.Metal tube + push-in fitting → immediate or gradual air loss

3.Hard plastic tube + quick coupling → unstable grip, vibration-induced leaks

Each case increases compressor load and energy consumption. Industry data from compressed air efficiency studies consistently shows that even small leaks can account for 20–30% of total air loss in poorly matched systems (industry energy audits).

Below is a simplified reference table used by many automation engineers during system design:

Tube Material | Typical Hardness | Recommended Fitting Type |

PU Tube | Soft / Elastic | Pneumatic Push In Fitting, Quick Coupling |

PA Tube (Flexible) | Semi-rigid | Push In Fitting, Quick Coupling |

PA Tube (Rigid) | Hard | Compression Fitting |

Stainless Steel | Very Hard | Compression Fitting |

Copper / Brass Pipe | Very Hard | Compression or Welded Fitting |

Aluminum Tube | Hard | Compression Fitting |

This kind of table is often included in a pneumatic fittings selection guide used by distributors and OEM sales teams.

Even with the correct fitting type, installation matters. Push-in fittings require clean, square-cut tube ends. A slight angle or scratch can compromise the O-ring seal. Compression fittings demand correct torque—over-tightening can deform the ferrule, while under-tightening leads to leaks. These details are often overlooked but play a major role in system reliability.

Experienced engineers know that choosing the right Pneumatic Quick Coupling is only half the job; proper installation completes the seal.

At FOKCA Automation, fitting designs are developed with tube behavior in mind. Push-in fittings are optimized for PU and PA elasticity, while compression fittings are machined to maintain consistent ferrule deformation on metal tubes. For OEM and ODM customers, this means fittings can be matched not only by size, but by material interaction and long-term performance.

FOKCA’s ability to supply standard-compatible fittings alongside customized solutions helps distributors reduce SKU complexity while maintaining correct tube–fitting pairing across different markets. This is especially valuable when replacing or cross-referencing global brands in cost-sensitive projects.

Choosing between a Pneumatic Push In Fitting, a Pneumatic Quick Coupling, or a compression fitting is not a matter of preference. It is a direct response to tube material and hardness. Soft tubes need elastic sealing. Hard tubes need mechanical compression. Metal pipes may require welding. When these rules are followed, pneumatic systems remain efficient, quiet, and reliable.

For engineers, distributors, and procurement teams alike, understanding this material logic turns fitting selection from guesswork into a repeatable, professional process—and prevents leaks long before they appear.

If you have any requirements or questions,please feel free to Contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap