Dec 31, 2025

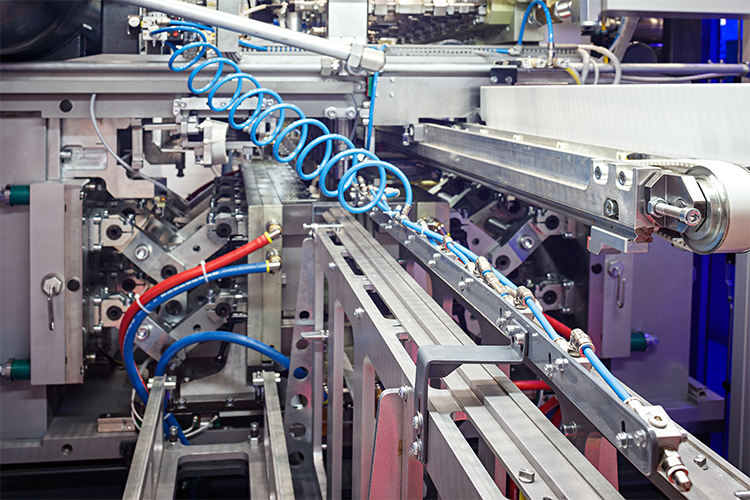

Long-distance PU tubing routing is a critical aspect of modern pneumatic and fluid systems. Improperly secured tubing can lead to wear, vibration damage, or leakage, affecting system reliability and maintenance efficiency. For distributors, engineers, and procurement managers, understanding the best practices for securing PU tubing ensures long-term performance and cost savings.

A well-planned tubing routing reduces stress and minimizes sharp bends. Using software tools like SolidWorks tubing add-in or SolidWorks pipe drawing helps engineers visualize the routing path and identify potential interference points before installation. Smooth, continuous paths not only protect the tube from mechanical stress but also improve airflow or fluid dynamics.

Long-distance PU tubing should be supported at regular intervals to prevent sagging or vibration. Plastic clamps, adjustable brackets, or specialized PU tubing holders can provide stable support. Selecting the proper support spacing depends on tube diameter, system pressure, and environmental conditions. FOKCA PU tubing comes with compatible clamps designed to simplify installation while maintaining tube integrity.

Vibration can accelerate tube wear, especially in machinery with moving parts. Incorporating vibration-damping clips or flexible loops in the routing path reduces contact stress. Where tubes cross metal edges or other components, protective sleeves or grommets prevent abrasion, extending service life.

During design, ensure that long tubing runs remain accessible for inspection and replacement. Strategic placement of junctions or connectors allows sections to be disconnected without disassembling the entire system. Using modular FOKCA fittings facilitates quick maintenance while maintaining system reliability.

For engineers using SolidWorks hydraulic hose routing or tubing in SolidWorks, embedding routing rules directly in the CAD model ensures accurate fabrication drawings and assembly instructions. It also streamlines communication between design and production teams, reducing errors in long-distance tube installation.

FOKCA provides high-quality PU tubing and supporting accessories optimized for long-distance installations. With OEM/ODM capabilities, FOKCA ensures tubing lengths, diameters, and fittings match the exact system requirements, improving reliability, reducing downtime, and enhancing overall system efficiency.

If you have any requirements or questions,please feel free to Contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap