Dec 30, 2025

In industrial automation, Polyurethane pneumatic tubes are widely used for their flexibility, chemical resistance, and ease of installation. However, like all materials, PU tubes are not immune to aging. Recognizing early signs of fatigue helps prevent unexpected downtime, reduces maintenance costs, and ensures consistent performance in pneumatic systems.

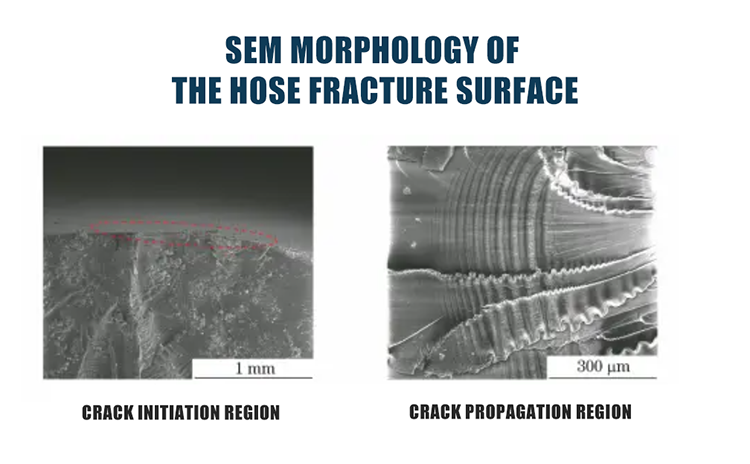

One of the most straightforward ways to assess tube health is through visual inspection. Discoloration, surface cracks, or brittleness often indicate polymer degradation. In long-term installations, a PU tube may appear slightly hardened or develop micro-fissures, especially near fittings where stress concentration occurs. Routine inspection allows engineers to identify high-risk areas before failure.

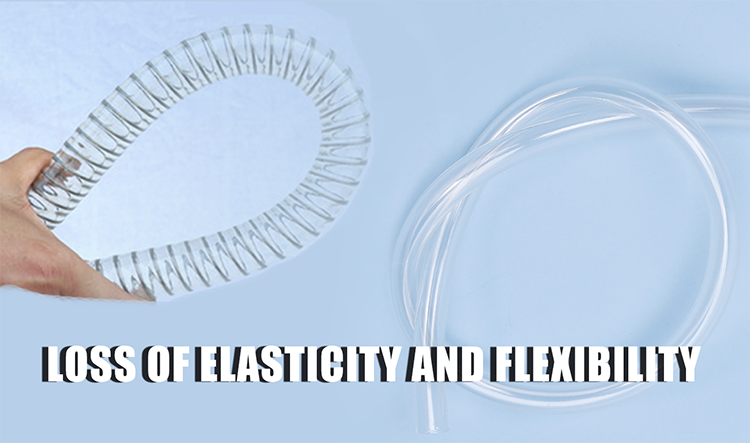

Flexible pneumatic hoses should return to their original shape after bending. If a tube becomes stiff, resists bending, or shows permanent deformation, it is a sign of material fatigue. Over time, repeated expansion and contraction under normal working pressure gradually reduce the polymer’s elasticity, shortening the tube’s service life. FOKCA’s anti-aging PU tubes are engineered to maintain flexibility longer, even under dynamic pressure cycles.

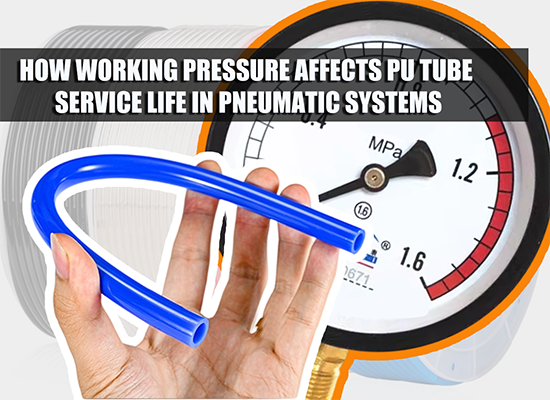

PU tubes under continuous use may experience a drop in pressure tolerance. Minor leaks or slower system response can be early indicators of aging. For industrial automation tubing, maintaining consistent air flow and pressure is critical. Using high-quality FOKCA polyurethane pneumatic tubes ensures that pressure performance remains stable over time, extending tube lifespan and system reliability.

Another sign of aging is surface hardening. In high-temperature or high-cycle environments, PU tubes may lose the soft, flexible texture and become brittle. Brittle tubes are more prone to cracking under mechanical stress or vibration. Engineers and end-users can use simple manual tests, such as gently bending and compressing the tube, to detect reduced resilience.

Temperature fluctuations, UV exposure, moisture, and chemical contact can all accelerate PU tube fatigue. Outdoor installations or proximity to heat sources are particularly at risk. FOKCA’s tubing series addresses these challenges with enhanced material formulation and protective layers, ensuring anti-aging properties and stable performance in diverse environments.

To maximize the service life of flexible pneumatic hoses, regular monitoring is essential. Schedule inspections for discoloration, brittleness, micro-cracks, and pressure performance. Replace tubes showing any of these signs to prevent unexpected system downtime. For distributors, engineers, and procurement teams, specifying FOKCA anti-aging PU tubes guarantees longer maintenance intervals, reduced replacement frequency, and higher customer satisfaction.

PU tube fatigue is cumulative, not sudden. Detecting visual changes, testing flexibility, monitoring pressure performance, and considering environmental factors are key to proactively maintaining tube reliability. Using FOKCA polyurethane pneumatic tubes provides a reliable solution with extended lifespan, helping your automation systems perform safely and efficiently.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap