Dec 22, 2025

When it comes to pneumatic systems, pneumatic quick couplings are widely recognized for their efficiency in connecting and disconnecting air lines. However, a common question arises among engineers, distributors, and end-users: Can these couplings handle water? The answer is nuanced. While standard pneumatic quick couplings can handle cold water under controlled conditions, high-temperature water or steam can compromise their performance. Understanding the materials, sealing mechanisms, and limitations is key to ensuring both reliability and safety in industrial applications.

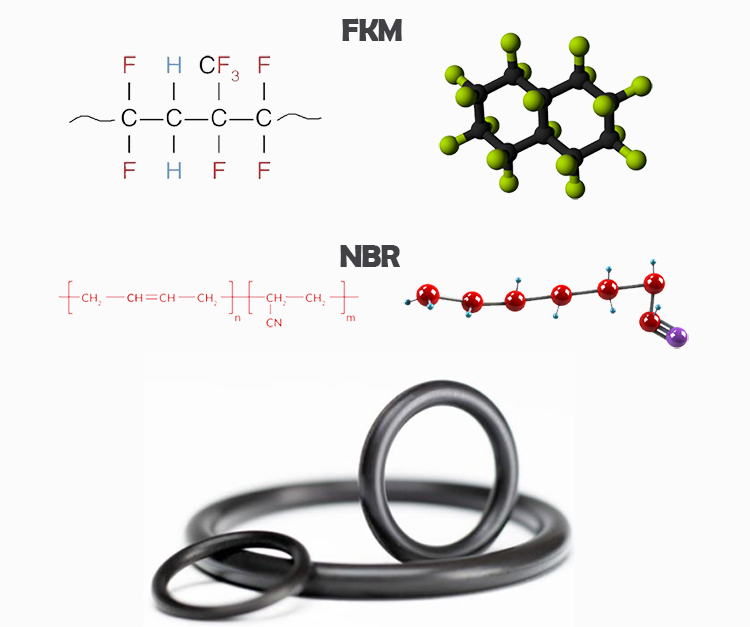

Pneumatic quick couplings come in various materials, including zinc-plated steel, brass, and stainless steel. The sealing element, usually a rubber ring, is the critical component determining water compatibility. Most standard couplings use NBR (Nitrile Butadiene Rubber) seals, prized for their flexibility and durability in air applications. However, NBR has limitations when exposed to hot water or steam, as it is prone to hydrolysis, oxidation, and hardening over time.

On the other hand, FKM (Fluoroelastomer) seals can withstand higher temperatures and resist water degradation, making them suitable for applications involving hot liquids. A simple comparison highlights the difference:

Material | Max Temp (°C) | Water Resistance | Steam Resistance | Notes |

NBR | 80 | Good (cold) | Poor | Risk of cracking in hot water |

FKM | 200 | Excellent | Excellent | Ideal for hot water & steam |

EPDM | 150 | Excellent | Fair | Suitable for moderate heat water |

Data source: Industry material standards

By choosing the right material combination, users can ensure safe operation while preventing early failure of the coupling.

Standard quick couplings for hose or open flow quick disconnect hose couplings for air and water are typically designed for cold water applications. For example, in pneumatic systems used in cooling lines or laboratory setups, these couplings can transport water safely at low temperatures and moderate pressures.

However, even cold water over long periods can gradually impact the seal if maintenance is neglected. Regular inspection of the NBR sealing ring ensures that no cracks or deformation compromise the connection.

In practice, using standard pneumatic couplings with water is feasible for low-temperature, low-pressure environments, but caution is required when temperature or operational pressure increases.

The main limitation arises from NBR seals’ inability to withstand high temperatures. When exposed to hot water or steam:

◆Hydrolysis occurs, breaking down the polymer chains.

◆Oxidation accelerates, leading to hardening.

◆The seal may crack or shrink, causing leaks.

This not only reduces the efficiency of the connection but can also lead to safety hazards, particularly in automated systems or industrial settings where unexpected leaks may disrupt operations.

Thus, for any application involving temperatures above 80°C or steam, NBR-based couplings should be avoided.

For high-temperature or steam applications, stainless steel couplings with FKM seals are the recommended choice. This combination offers:

◆High corrosion resistance

◆Excellent thermal stability

◆Long-term durability in water and steam

Feature | NBR | FKM | EPDM |

Cold water | ✅ | ✅ | ✅ |

Hot water (100°C+) | ❌ | ✅ | ⚠ |

Steam | ❌ | ✅ | ⚠ |

Durability | Moderate | Excellent | Good |

By selecting the right pneumatic coupling type, engineers can achieve reliable performance for both air and water systems.

FOKCA Automation Ltd. offers a wide range of pneumatic quick connect types tailored for different applications. For systems that may handle water, our stainless steel quick couplings with FKM seals provide both safety and efficiency.

Key benefits of FOKCA couplings:

1.Versatility: Suitable for air, cold water, and hot water applications.

2.Customizable: OEM/ODM options available for specialized hoses or operating conditions.

3.Durability: Resistant to corrosion, high temperature, and repeated connection cycles.

We also supply other options including CEJN quick coupling equivalents and quick coupling connectors that meet international standards, ensuring compatibility across industries.

1.Temperature Monitoring: Ensure the water temperature does not exceed the seal’s rated maximum.

2.Regular Maintenance: Inspect NBR or FKM seals periodically for cracks or deformation.

3.Pressure Control: Avoid exceeding the coupling’s rated pressure to prevent seal extrusion.

4.Proper Selection: For high-temperature or industrial water applications, always choose FKM seals and stainless steel bodies.

Following these practices can extend the life of your couplings, maintain system efficiency, and prevent unexpected downtime.

Pneumatic quick couplings can handle water under certain conditions, primarily low temperature and low pressure. For demanding environments involving hot water or steam, stainless steel bodies with FKM seals provide the necessary reliability and safety. With FOKCA’s global supply capabilities and OEM/ODM flexibility, distributors, engineers, and end-users can select couplings that meet both operational and safety requirements, ensuring your pneumatic systems operate efficiently in any environment.

For more information or to place an order, feel free to contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap