Dec 08, 2025

When engineers work with rigid metal tubes—copper, stainless steel, or aluminum—ordinary push-in or push-lock connectors no longer meet the mechanical gripping force required for long-term sealing. This is where the ferrule compression fitting (also known as ferrule pipe fitting, brass compression fittings, compression fitting ferrule, etc.) becomes the most dependable solution. By creating a controlled deformation of the ferrule, the fitting locks permanently onto the tube, providing stability that soft-tube connectors simply cannot achieve.

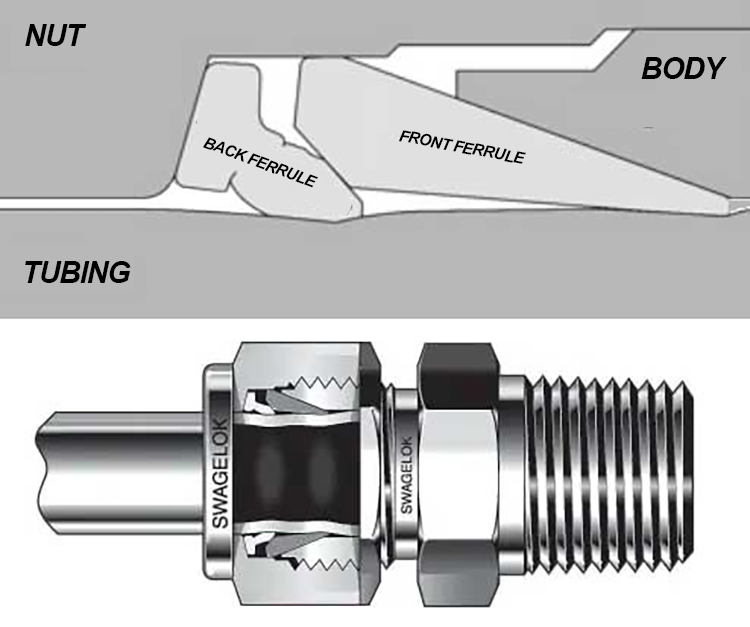

A compression fitting relies on three precisely matched elements: compression nut, ferrule, and the body’s tapered seat. When tightened, the ferrule deforms slightly and “bites” into the tube surface, creating both a strong mechanical hold and a stable metal-to-metal seal.

For sizes such as 3/8 compression fitting or 3/4 compression fitting, this controlled deformation becomes essential in systems exposed to vibration or fluctuating pressure.

On production lines, cooling loops, lubrication systems, and instrumentation lines often depend on these fittings. Where push-in fittings may loosen over time, a proper ferrule fitting becomes tighter under vibration, reducing the maintenance workload for equipment engineers.

Rigid metal tubes offer excellent ageing resistance, pressure stability, and temperature tolerance, but their hardness also makes traditional soft-tube connectors unsuitable. A ferrule fitting compensates for this by forming a single-use plastic deformation around the tube.

In general pneumatic operations (10–25 bar), the sealing reliability is 3–5 times higher than push-in fittings according to industrial maintenance reports.

This is why industries such as instrumentation, refrigeration, and oil sampling continue to rely on ferrule technology—even when other connectors seem faster to install.

Nickel-plated brass compression fittings are engineered for long-term stability, especially for distributors, engineers, and equipment builders who work with mixed-material tubing.

1. Precision-machined cone seat

A smooth contact surface helps create a consistent metal-to-metal seal, reducing the chance of micro-leakage in hydraulic or mist-lubrication circuits.

2. Controlled ferrule deformation

A high-quality ferrule forms a uniform 360° compression ring. Lower-grade products sometimes create uneven bite marks, resulting in premature loosening.

3. Nickel-plating for corrosion resistance

Compared with standard brass, nickel-plated fittings perform better in humid, oily, or mildly corrosive environments—common in food machinery and pressure measurement setups.

For deeper structural details, see the internal page:

Internal link: Ferrule Compression Fitting – Technical Specifications (/ferrule-compression-fittings)

Fast installation but limited vibration and pressure resistance. Not suitable for rigid metal tubes.

Threaded fitting

Useful for general piping but depends heavily on sealants and lacks the mechanical grip of ferrules.

Ferrule compression fitting

Designed for rigid tubes, offers superior locking strength, and is available in 3/8, 1/2, 3/4 and other common sizes.

A quick comparison helps simplify selection:

Fitting Type | Pipe Material | Installation Speed | Vibration Resistance | Typical Use |

Push-in | Soft tube | Fast | Low | General pneumatics |

Threaded | Soft/metal | Medium | Medium | Low-pressure systems |

Ferrule compression fitting | Rigid metal tube | Medium | High | Instrumentation, hydraulic, cooling |

Source: Industrial maintenance survey (market analysis data)

Mixed imperial and metric systems make it necessary for engineers and distributors to keep multiple sizes in stock.

3/8 Compression Fitting

Widely used in sampling lines, analytical gas systems, and instrument connections where stable flow and moderate pressure are required.

3/4 Compression Fitting

Common in cooling water loops, oil lines, and larger machinery needing durable tube fixation. Nickel-plated brass or stainless steel versions offer the best long-term performance.

FOKCA supports OEM / ODM machining, including custom cone angles, ferrule thickness, and materials—ideal for equipment manufacturers requiring precise fitting compatibility.

Many leaking issues originate from incorrect installation rather than fitting quality. For rigid tubes, these steps are critical:

◆Use a square, burr-free tube cut

An angled cut prevents uniform ferrule compression and may cause localized leakage.

◆Deburr thoroughly

Inner and outer burrs can scratch the ferrule, reducing sealing integrity.

◆Follow the recommended tightening turns

Fittings are often specified for ¾ turn or 1¼ turns depending on size.

Internal link: Installation Guide (/installation-guide)

◆Avoid reusing ferrules

After deformation, the ferrule’s geometry is fixed. Reinstalling reduces grip strength.

◆Perform a pressure test

High-pressure systems should be tested at 1.5× operating pressure with nitrogen or dry air.

FOKCA provides a competitive, globally compatible solution for distributors, technical teams, and procurement managers:

Nickel-plated brass for enhanced corrosion resistance

Interchangeable with major international standards

OEM/ODM available for ferrule geometry, angles, and materials

Precise tolerances ensuring stable fit with 3/8, 1/2, 3/4 tubes

Reliable stock for distributors building regional inventories

If you would like to learn more about ferrule compression fitting push-in fittings or pneumatic hoses , feel free to contact us . FOKCA will provide you with the most professional service.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-RetardantLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap