Dec 10, 2025

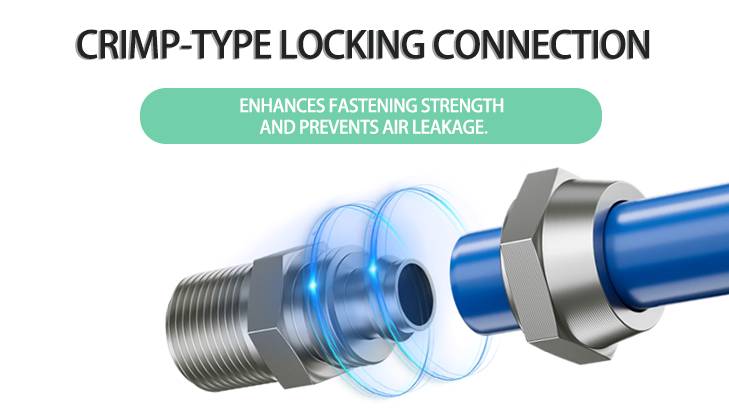

Rapid pneumatic fittings sit in a unique position between push-in fittings and compression fittings. They use a tightening nut similar to a ferrule design, yet maintain the convenience of push-in connectors by allowing repeated disassembly and flexible tube changes. This structure makes them valuable in pneumatic lines requiring both reliability and quick maintenance. For distributors, machine builders, and maintenance engineers, mastering rapid pneumatic fittings helps reduce leakage risk, streamline assembly, and standardize spare-parts inventory.

Many pneumatic systems operate in environments where a standard push-in fitting may loosen due to frequent vibration, but a ferrule-type fitting feels excessive because it permanently bites into the tube.

Rapid pneumatic fittings address this gap. The tightening nut provides firm mechanical retention comparable to a ferrule, while the inner collet grips the tubing without permanent damage, allowing easy replacement.

A packaging machine engineer once described a recurring issue on a reciprocating arm: push-in fittings kept backing off after a few hundred thousand cycles.

Switching to rapid air fittings stabilized the motion circuit without forcing the team to replace the entire tube each time. This illustrates why industries such as logistics automation, wood-processing equipment,

and textile machines increasingly use rapid pneumatic fittings in mid-vibration zones.

A rapid fitting consists of four main components: nickel-plated brass body, locking nut, collet, and sealing ring. The nut compresses the collet uniformly around the tube, creating 360-degree holding force.

The compression strength can be adjusted manually, giving technicians better control when dealing with tubes of different hardness.

Many installations fail because the nut is overtightened. When the collet is excessively compressed, it creates subtle surface damage on polyurethane tubes, which leads to micro-leaks after weeks of pressure cycling. A simple rule engineers follow is to tighten the nut only until the tube cannot be pulled out with moderate finger force. This approach protects the seal while maintaining stability under up to 15 bar in typical industrial lines.

For distributors and maintenance teams, having fittings with nickel-plated brass ensures better corrosion resistance, especially when used with lubricated compressors or slightly humid compressed air.

FOKCA’s rapid fittings adopt industrial-grade plating thickness, which provides longer service life in factory environments with oil mist and dust.

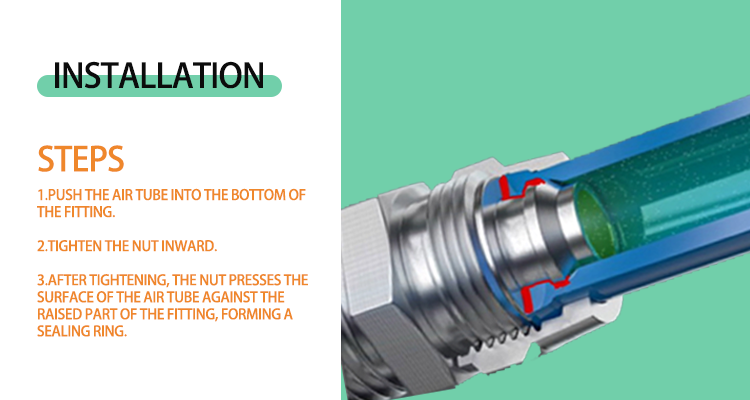

Installation requires a short, disciplined sequence.

First, the tube must be cut fully perpendicular using a sharp tube cutter. A diagonal or rough cut reduces the effective sealing surface.

Then the nut is placed onto the tube before inserting the tube into the fitting body. As the nut is tightened, the collet compresses evenly.

When replacing tubes in maintenance operations, technicians often skip cleaning the fitting body.

Dust inside the metal housing can interfere with sealing performance. A short air blast helps remove debris before inserting the new tube.

Below is a comparison table often used in training sessions for new equipment technicians:

Connection Type | Reusability | Vibration Resistance | Installation Speed | Tube Wear |

Push-in fitting | Excellent | Medium | Very fast | Low |

Ferrule fitting | Very low | High | Slow | High |

Rapid pneumatic fitting | High | High | Fast | Moderate |

Data based on general mechanical engineering field practice.

Choosing the correct tubing is essential to fully utilize the advantages of rapid fittings. PU (polyurethane) tubes are widely used because they compress well under the collet and maintain elasticity.

Their slight softness allows the nut-locking mechanism to grip securely without surface cracking. In contrast, PA (nylon) tubes require careful torque control because they are harder and less forgiving.

A common technique among senior maintenance staff is to lightly rotate the tube during insertion to feel whether the collet seats properly. With rigid nylon tubes, engineers sometimes warm the tube end slightly to enhance flexibility in low-temperature environments.

For procurement teams, adopting a standardized tube-and-fitting pairing reduces failure rates.

FOKCA’s rapid pneumatic fittings are tested with both PU and PA tubing under ISO 4414 pneumatic safety guidelines, giving buyers confidence that the system will maintain sealing integrity over long duty cycles.

Rapid air fittings thrive in environments where maintenance frequency and mechanical stress intersect. In sorting lines, cylinder speed adjustments require quick tube replacement. Rapid fittings allow this without discarding expensive nylon tubing.

On textile machines, constant vibration from looms demands a connection stronger than push-in designs. Rapid fittings prevent gradual loosening while still allowing easy service access during shift changes.

One distributor serving woodworking factories reported a reduction of nearly 40% in fitting-related downtime after adopting rapid-nut designs for dust-laden environments. The sealing ring inside the fitting provided extra protection against fine particles entering the mixture of compressed air and sawdust.

FOKCA offers rapid fittings with nickel-plated brass that resist corrosion from cutting fluids, making them suitable for CNC automatic loaders, robotic arms, and pneumatic tool systems. Their consistent dimensions help distributors supply compatible replacements across multiple equipment brands.

Selecting the correct fitting requires consideration of multiple parameters: tube diameter, working pressure, temperature, medium, and equipment vibration level. For sales engineers, these parameters provide a practical checklist when advising clients.

A useful rule:

1.Choose rapid fittings when the circuit sees vibration + frequent maintenance.

2.Keep push-in fittings for static or semi-static lines.

3.Use ferrule fittings for high-pressure, critical applications.

Distributors benefit from stocking rapid fittings in the most common thread types: BSPT, NPT, G-thread. FOKCA supports OEM and ODM services, enabling private-labeling for local distributors who require customized packaging or threading specifications tailored to regional markets.

For machine builders, rapid fittings simplify after-sales service. Equipment manuals often instruct operators to release the nut, replace the tube, and re-tighten without removing adjacent components. This reduces downtime and eliminates the need to cut new ferrules on every maintenance cycle.

FOKCA focuses on nickel-plated brass rapid fittings, ensuring high durability in oily, humid, and dusty environments common to industrial workshops. The internal geometry is designed for smooth air passage, minimizing flow turbulence.

For OEM clients, FOKCA can adjust sealing ring hardness, customize nut color for identification, or modify collet material to suit special tubing.

Because FOKCA supplies a complete pneumatic range—cylinders, valves, air preparation units, pneumatic hoses, and hydraulic quick couplings—distributors and equipment builders can consolidate procurement.

This reduces supplier complexity while ensuring all components share consistent quality standards.

To view detailed specifications or request OEM customization support, click here to visit the rapid pneumatic fitting product page.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap