Dec 18, 2025

In fluid handling systems, material selection often determines whether a system runs reliably for years or fails quietly from the inside. Among fluoropolymers, PFA stands out as a material chosen not for cost savings, but for performance under conditions where ordinary plastics simply cannot survive. Engineers, buyers, and distributors often ask about PFA meaning or PFA definition, yet the real value of PFA becomes clear only when its behavior in real applications is understood.

PFA, short for Perfluoroalkoxy Alkane, is a fully fluorinated plastic material developed to combine the chemical resistance of PTFE with improved processability. Unlike conventional plastic hoses, PFA material maintains its molecular stability even when exposed to aggressive chemicals, ultra-pure media, or elevated temperatures.

From a technical perspective, the defining feature of PFA plastic material is its fully fluorinated carbon chain, which resists chemical attack almost entirely. This makes PFA suitable for applications where PVC, PU, or even nylon hoses degrade, swell, or leach contaminants over time. For industries that cannot tolerate contamination or material breakdown, PFA is not an upgrade—it is a requirement.

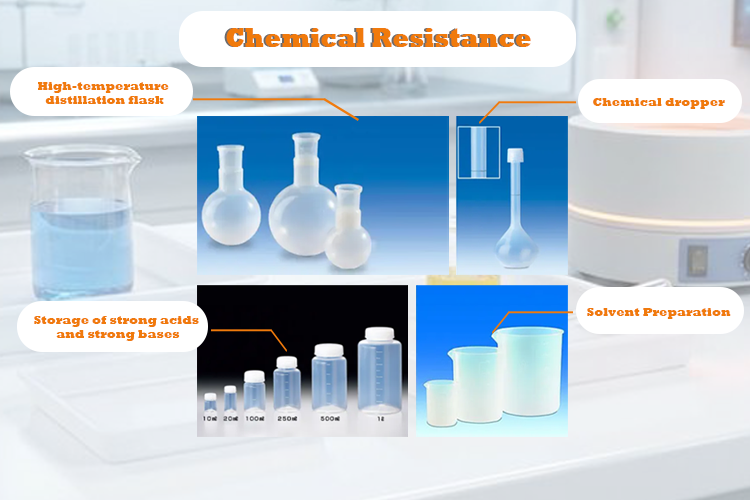

Chemical compatibility is the primary reason many engineers specify PFA material. It is resistant to nearly all acids, bases, solvents, and oxidizing agents, including substances that rapidly degrade standard polymers. According to industry material compatibility data published by chemical engineering associations, PFA shows near-universal chemical inertness across a wide pH range.

In practical terms, this means PFA tubes do not absorb chemicals, do not release plasticizers, and do not react with process media. For water treatment, chemical dosing, and analytical systems, this stability directly improves system accuracy and service life.

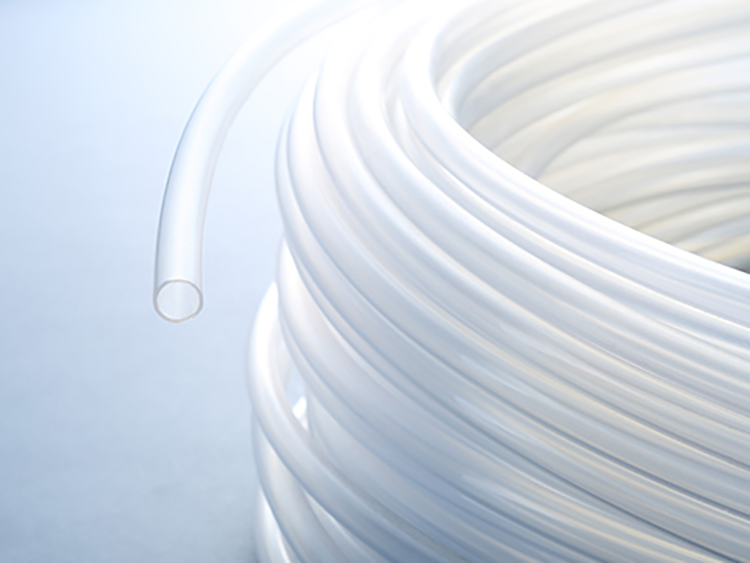

Although PFA is not chosen for high-pressure hydraulic systems, it performs exceptionally well in low-to-medium pressure applications where chemical integrity is critical. PFA hose retains flexibility over time and resists micro-cracking caused by vibration or repeated bending.

In real installations, this translates into fewer leaks, reduced maintenance, and longer replacement cycles. For equipment manufacturers and system integrators, specifying PFA plastic material reduces after-sales risk and improves perceived product quality for end users.

Many industries rely on PFA polyfluoroalkoxy tubes not because alternatives are unavailable, but because failure is unacceptable. Common applications include:

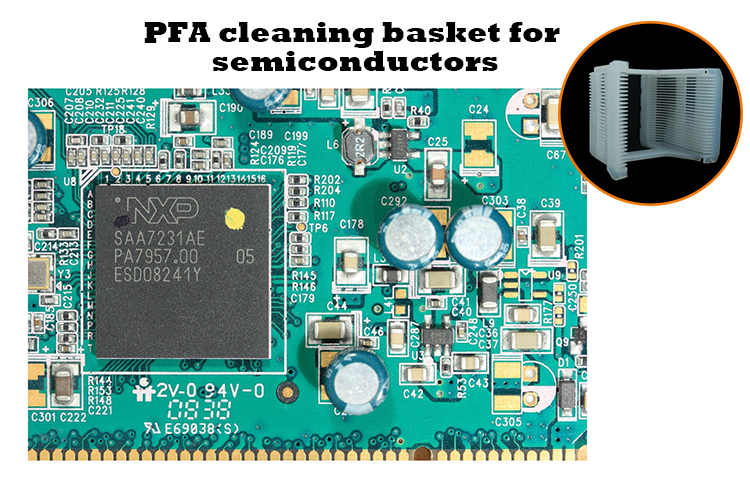

1.Semiconductor wet process equipment

2.Pharmaceutical fluid transfer systems

3.Chemical dosing and metering systems

4.High-purity water and ultrapure water (UPW) lines

5.Laboratory and analytical instrumentation

In these environments, material degradation is not merely a maintenance issue—it can compromise product quality, safety, or regulatory compliance.

As industrial processes become more precise and regulated, materials once considered “good enough” are being replaced. PFA plastic material aligns with this shift, offering predictability, cleanliness, and long-term stability.

For distributors, engineers, and factory operators, understanding the true PFA meaning goes beyond a definition. It is about recognizing when material choice protects systems, processes, and reputations.

As a leading China PFA hose factory, FOKCA Automation offers a comprehensive range of PFA pneumatic hoses suitable for OEM and ODM integration. Key advantages include:

1.Dimensional precision: Ensures leak-free fittings and consistent performance

2.Custom lengths and diameters: Supports compact layouts and complex equipment design

3.High-purity material with smooth inner walls: Prevents particle accumulation in high-precision pneumatic systems

4.Compatibility with multiple connectors: Supports standard quick fittings and customized interfaces

Strict control over raw material selection and extrusion processes ensures consistent performance across production batches, providing distributors and OEM clients with predictable, reliable products.

Contact us anytime—we are your reliable partner in pneumatic technology.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic SystemsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap