Dec 24, 2025

In modern pneumatic design, space is no longer a luxury. Control cabinets are slimmer, modular machines integrate more functions into smaller footprints, and equipment builders are constantly asked to “fit more into less.” In this context, the mini quick coupling has become more than a convenience component—it is a practical solution to a real engineering bottleneck. With an overall size of only about 40% of standard quick couplings, mini versions enable reliable air connections where traditional fittings simply do not fit.

A quick coupling is a mechanical connector that allows fast connection and disconnection of fluid or air lines without tools. When engineers ask what is a quick coupler, the classic answer focuses on speed and convenience. However, in compact automation, size becomes just as important as function.

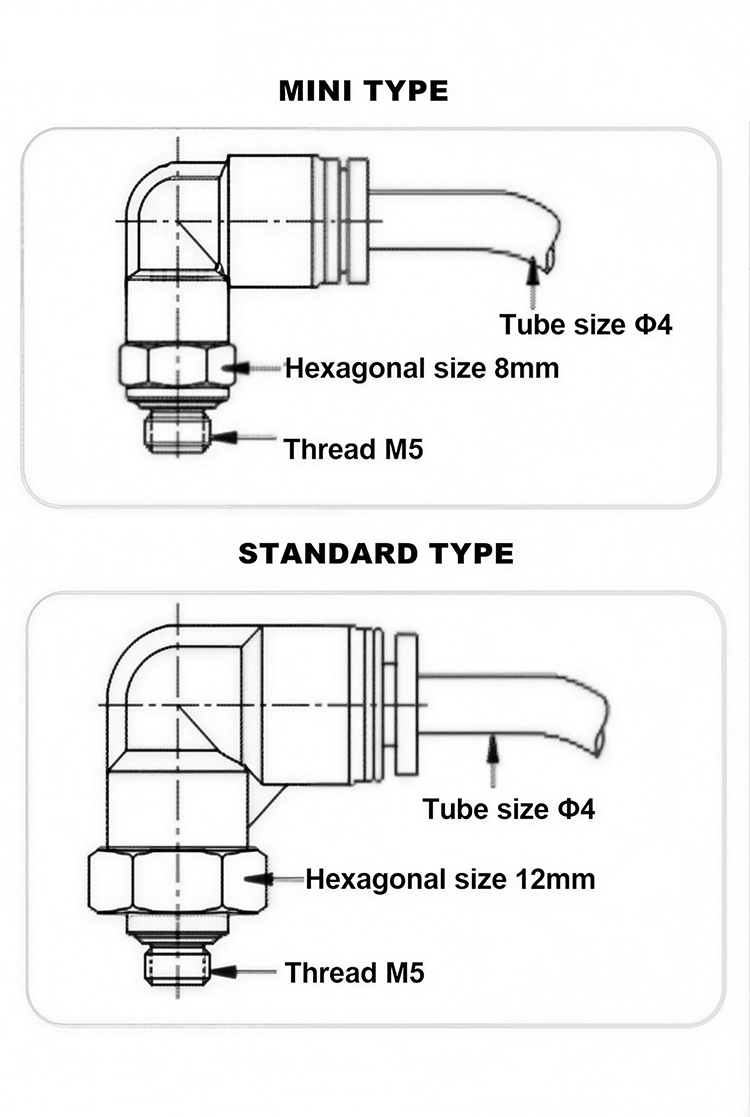

A Mini Type Pneumatic Push In Fittings follows the same working principle as standard models but is redesigned with reduced outer diameter, shorter body length, and lighter weight. This compact geometry makes it especially suitable for integrated equipment, portable tools, and dense pneumatic manifolds. In many installations, reducing connector size is the only way to maintain clean routing and safe assembly without redesigning the entire system.

Understanding how does a quick coupler work helps clarify why miniaturization is possible without sacrificing reliability. Inside both standard and mini types, the mechanism relies on spring-loaded locking balls or pins combined with an internal valve. When the plug (male) is inserted into the socket (female), the locking elements engage automatically, creating a sealed flow path.

In mini quick connect fittings, the same principle is applied with tighter tolerances and optimized internal geometry. Advances in CNC machining and surface treatment allow manufacturers to maintain sealing performance even with smaller sealing areas. For engineers, this means compact size does not imply fragile operation, as long as the coupling is designed and tested correctly.

When comparing mini type quick disconnect pneumatic fittings to standard European quick disconnect air fittings, the difference is immediately visible. Standard couplings are robust and easy to handle, but they occupy valuable space and add weight at connection points.

Mini couplings typically reduce body volume by around 60%, while still supporting common pneumatic pressures used in automation. This reduction improves accessibility during installation and maintenance, especially inside enclosed machines. For distributors, this also creates a clear product segmentation: standard couplings for general use, and mini versions for compact or high-density applications.

Questions about quick connect coupler sizes often arise during system design or retrofitting. Size selection is not only about thread dimensions, but also about flow rate, pressure drop, and ergonomics.

Mini couplings are ideal for low to medium flow requirements, such as sensor air supply, actuator control lines, or handheld pneumatic tools. While their internal bore is smaller, modern designs minimize pressure loss through smooth internal channels. Engineers should evaluate actual air consumption, not just nominal line size, before assuming a mini coupling is insufficient.

The advantage of a mini quick release coupling becomes most apparent in real applications. In integrated assembly machines, where multiple air lines converge in tight spaces, smaller couplings reduce interference and improve serviceability. In portable devices, lighter connectors reduce operator fatigue and improve handling.

Specialized versions, such as handle with mini quick coupling, are commonly used in handheld pneumatic tools, test equipment, and maintenance kits. Even outside classic factory automation, compact couplings are seen in niche applications like mini excavator quick coupling systems, where space and weight constraints drive design decisions.

Mini couplings are available in multiple material options. A miniature brass quick disconnect coupling for air is widely used due to its corrosion resistance, machinability, and cost-effectiveness. Stainless steel variants serve harsher environments, while hardened steel versions handle higher mechanical stress.

Certain specialized designs, such as mini quick coupling chuck or quick coupling minimess, are tailored for testing, measurement, or hydraulic-adjacent applications where precision and compactness are critical. The variety of designs allows engineers and buyers to match coupling performance closely to the operating environment.

In global markets, compatibility matters. Many customers specifically request European quick disconnect air fittings, even in mini form, to ensure interchangeability with existing plugs and tools. Mini couplings designed to European profiles allow seamless integration without changing mating components across the system.

For distributors, offering mini couplings that follow recognized standards simplifies stocking and reduces after-sales issues. For end users, it ensures that compact size does not lock them into proprietary ecosystems.

As a global pneumatic component supplier, FOKCA Automation provides a complete range of mini quick coupling solutions designed for space-limited systems. Our products are engineered to deliver reliable sealing and consistent performance despite their reduced size, making them suitable for integrated equipment and compact automation modules.

Beyond standard offerings, FOKCA supports OEM and ODM projects, helping customers adapt coupling size, material, and interface to specific application needs. Combined with our pneumatic tubing, valves, and fittings, mini couplings become part of a cohesive system rather than an isolated component.

The growing adoption of mini quick connect fittings reflects a broader trend in automation: smarter, denser, and more efficient system design. By occupying only a fraction of the space of standard couplings, mini versions unlock new layout possibilities without sacrificing functionality.

For distributors, engineers, and end users alike, understanding when and how to apply mini quick couplings turns a simple connector into a strategic choice. In environments where every millimeter counts, compact pneumatic connections are not just convenient—they are essential.

For more information or to place an order, feel free to contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap