Dec 29, 2025

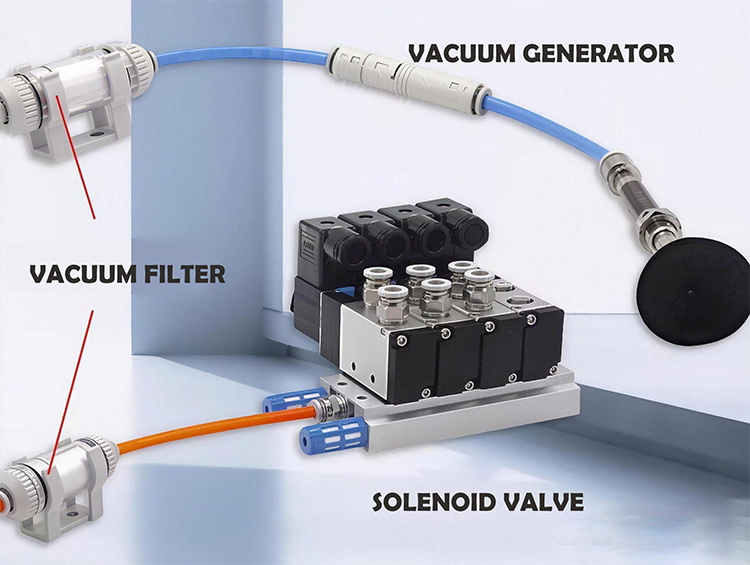

In automated handling systems, a vacuum filter is rarely the most expensive component, yet it often determines the service life of the entire vacuum circuit. In applications using suction cups to pick and place workpieces, fine dust, powder, paper fibers or machining residues are easily drawn into the airflow. Without proper filtration, these contaminants quickly reach the vacuum generator, where internal nozzles and ejector passages are both precise and unforgiving. This is exactly why SMC vacuum filter solutions such as ZFC, VFC, VFR and ZFB series have become a standard choice in modern automation lines.

A vacuum suction system works much like breathing through a straw. When the airflow is clean, everything runs smoothly; when dust enters, performance degrades fast. In real factories, workpieces are rarely pristine. Cardboard boxes shed fibers, metal parts carry fine chips, and plastic components attract dust through static electricity. Once these particles are pulled into the system, the vacuum generator , often one of the most expensive pneumatic components, becomes vulnerable.

An SMC vacuum filter acts as the first line of defense. Positioned between the suction cup and the vacuum generator, it intercepts contaminants before they can cause wear, clogging, or unstable vacuum levels. Over time, this protection translates into lower maintenance costs, more stable vacuum performance, and fewer unexpected production stops—benefits that matter equally to equipment engineers and purchasing managers.

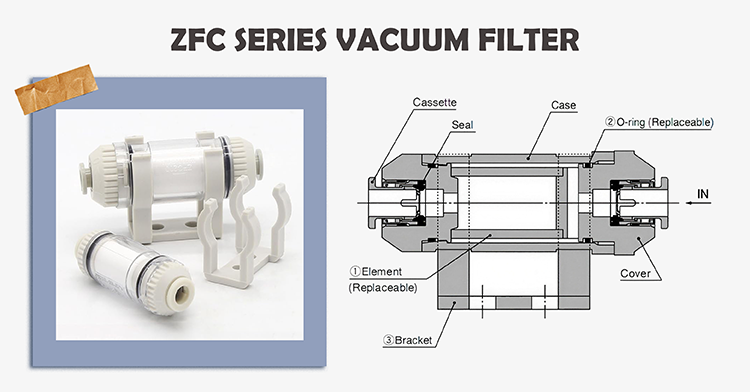

The ZFC vacuum filter is widely used in compact automation equipment where space is limited. Its lightweight body allows

installation directly near the suction cup, minimizing the distance contaminants can travel. This placement is especially effective when handling dusty workpieces such as paper, wood panels, or molded plastics.

A key advantage of the ZFC series lies in its easy filter element replacement, allowing operators to clean or change the element without dismantling the entire system. In high-cycle applications, this simplicity reduces downtime and keeps the vacuum line operating at a stable level, even under continuous operation.

For systems requiring higher airflow, the VFC vacuum filter offers a more robust structure and larger filtration capacity. This series is commonly selected in packaging lines or material handling equipment where multiple suction cups operate simultaneously.

In these scenarios, airflow demand fluctuates rapidly. A properly sized vacuum filter ensures that filtration does not become a bottleneck. The VFC series balances filtration efficiency with low pressure loss, helping maintain consistent suction force without overloading the vacuum generator.

The VFR series combines filtration with flow regulation, making it suitable for systems that require fine control over vacuum response. In pick-and-place robots handling fragile or lightweight parts, sudden pressure changes can cause slippage or deformation.

By integrating a regulator, the VFR series allows engineers to tune the vacuum level while still providing effective filtration. This dual function reduces the number of components in the circuit and simplifies system design, an advantage often appreciated by OEM equipment designers working under tight space constraints.

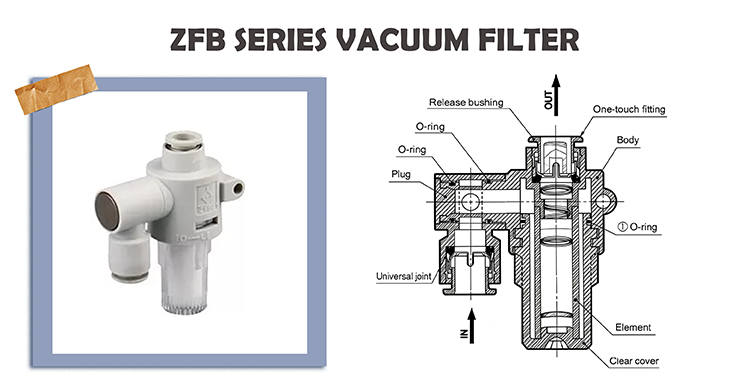

The ZFB vacuum filter focuses on inline installation and straightforward maintenance. It is often chosen when system layouts need flexibility or when retrofitting existing equipment. With its transparent housing, operators can visually check contamination levels at a glance, a small feature that greatly improves routine maintenance efficiency.

In production environments where operators manage multiple machines, this visual feedback helps prevent neglected filters from becoming a hidden cause of vacuum loss.

One of the most common mistakes in vacuum system design is undersizing the filter. A vacuum filter must have an intake flow rate equal to or greater than the vacuum generator’s flow capacity. When the filter becomes the limiting factor, airflow restriction leads to slower response times, reduced vacuum levels, and unstable suction.

Industry guidelines from pneumatic system design references emphasize that filtration components should never throttle airflow under normal operating conditions. Selecting an SMC vacuum filter with sufficient flow margin ensures that even as the filter element accumulates dust, performance remains within acceptable limits. In practice, engineers often choose a filter rated 20–30% above the generator’s nominal flow, providing a buffer for real-world conditions.

Higher filtration accuracy captures finer particles, but it also means the filter element loads faster. In dusty environments, ultra-fine filtration may increase maintenance frequency. The optimal balance depends on the application: semiconductor handling demands fine filtration, while packaging lines may prioritize long service intervals.

Placing the vacuum filter close to the suction cup reduces contamination travel but may complicate maintenance if access is limited. Conversely, centralized filters are easier to service but allow dust to move further into the system. Many OEMs solve this by using multiple compact filters near critical suction points.

Temperature, humidity, and chemical exposure also affect filter choice. Some applications benefit from metal-bodied vacuum filters for durability, while others prefer lightweight polymer designs. Understanding the operating environment helps avoid premature degradation and leakage.

In packaging automation, vacuum filters protect generators from cardboard dust and adhesive particles. In CNC loading systems, they intercept metal fines before they reach sensitive ejectors. In electronics assembly, filters prevent microscopic debris from destabilizing precise pick-and-place operations. Across these industries, the SMC vacuum filter plays a quiet but critical role in system reliability.

Market analyses from industrial automation reports consistently show that preventive components like filtration contribute significantly to overall equipment effectiveness (OEE), even though they represent a small portion of total system cost.

As a global pneumatic component supplier, FOKCA Automation supports customers who use SMC-compatible vacuum filter solutions across ZFC, VFC, VFR and ZFB series. For distributors and equipment manufacturers, this means access to OEM/ODM services, stable quality control, and flexible customization options for non-standard requirements.

Beyond standard products, FOKCA assists customers in flow rate matching, material selection, and application-specific optimization, helping avoid common selection pitfalls. For buyers managing long-term supply chains, consistent performance and reliable delivery are just as important as technical specifications.

A vacuum system rarely fails dramatically; instead, performance degrades quietly. Suction weakens, cycle times lengthen, and energy consumption rises. In many cases, the root cause traces back to inadequate filtration. Investing time in selecting the right vacuum filter is not merely a technical decision but a strategic one.

By choosing appropriate SMC vacuum filter series and ensuring correct flow matching, manufacturers protect their vacuum generators, stabilize production, and reduce total cost of ownership. In competitive manufacturing environments, these incremental gains often make the difference between reactive maintenance and truly reliable automation.

For more information or to place an order, feel free to contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap