Jan 05, 2026

In modern pneumatic systems, air leakage is often attributed to push-in fittings or valves. However, experienced technicians know that the problem frequently originates with the PU tube itself. A PU pipe is cut straight or at an angle can significantly influence its sealing performance. This detail may seem minor but is crucial for achieving reliable self-sealing connections.

Polyurethane tubing is widely used for its flexibility, abrasion resistance, and ease of installation. Yet, the sealing behavior of a PU tube relies on how its end interacts with the internal O-ring and stop inside the fitting. Improperly cut tubing can create microscopic gaps, allowing compressed air to escape even when the connector appears correctly installed. Over time, these leaks increase energy costs and reduce system efficiency, particularly in continuous-operation equipment.

A clean, perpendicular cut guarantees that the PU tube contacts the fitting evenly. When fully inserted, the tube face presses uniformly against the internal stop, allowing the O-ring to compress symmetrically around the tube’s outer diameter. This geometry supports true self-sealing, distributes pressure evenly, and reduces wear on the O-ring.

For distributors and end users managing multiple machines, straight cuts improve maintenance reliability and allow easier tube replacement without compromising system integrity.

Angled cuts often result from scissors, utility knives, or worn tools. While the PU hose may still fit the connector, only part of the tube reaches the internal stop. The O-ring compresses unevenly, creating partial seals instead of a full circumferential seal. Initial leak tests may pass, but the system can develop intermittent leaks during prolonged operation or under vibration.

In high-cycle applications, angled cuts accelerate O-ring deformation and reduce the lifespan of the sealing interface. This often leads to troubleshooting errors, as the source of leaks is mistakenly blamed on the fitting rather than installation.

Even small leaks caused by poor tube cutting have measurable effects. Studies on industrial compressed air systems show that leaks as small as 1 mm² can increase energy consumption by several percent. For factories with multiple pneumatic lines, this translates to higher compressor load, more frequent maintenance, and less stable system pressure—affecting actuator performance in automated production.

Professional installers follow simple yet effective rules:

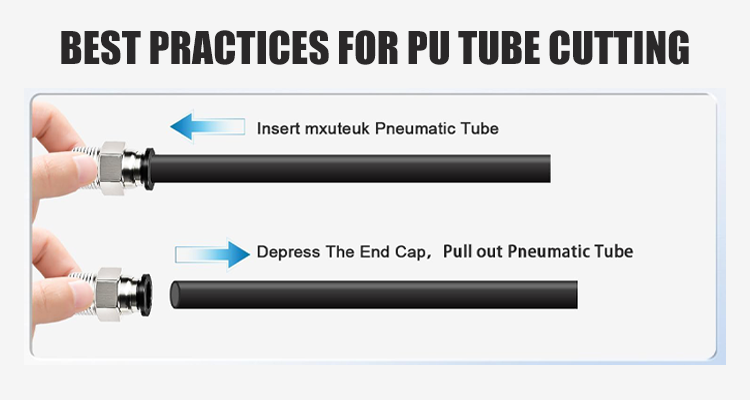

1.Always use a dedicated tube cutter designed for PU tubing to achieve clean, perpendicular cuts without deforming the tube wall.

2.Inspect the cut surface for flatness and smoothness. Remove any burrs or oval deformation. Recut if compression marks are visible.

3.Fully insert the tube into the fitting until it reaches the internal stop; partial insertion undermines even the best cut.

Even with proper cuts, sealing depends on consistent tube dimensions and material quality. Variations in outer diameter or hardness can affect how the O-ring engages the tube surface. FOKCA Automation provides PU tubing manufactured with controlled tolerances, ensuring consistent performance with push-in fittings.

For OEM customers, FOKCA offers customized options such as special hardness, color coding, and pre-cut lengths. This reduces assembly errors and enhances the self-sealing reliability of pneumatic systems.

For distributors, understanding the difference between angled and straight cuts reduces customer complaints and returns. Engineers benefit from improved system reliability without increasing BOM costs, while end users enjoy fewer leaks, lower energy bills, and more stable operations.

In pneumatic systems, reliability often hinges on small details rather than major components. Properly cut PU tubing, paired with high-quality fittings, ensures long-term, dependable self-sealing performance—the standard modern industrial operations demand.

If you have any requirements or questions,please feel free to Contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-RetardantLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap