Dec 19, 2025

In pneumatic and fluid handling systems, tubing is often treated as a simple consumable. In reality, the wrong material choice can lead to chemical incompatibility, premature aging, or unexpected downtime. Polypropylene (PP) tubing has become a widely accepted solution in many industrial environments because it balances chemical resistance, flexibility, and cost. For distributors, equipment engineers, and purchasing managers, understanding polypropylene material characteristics helps ensure the tubing performs reliably throughout the system’s service life.

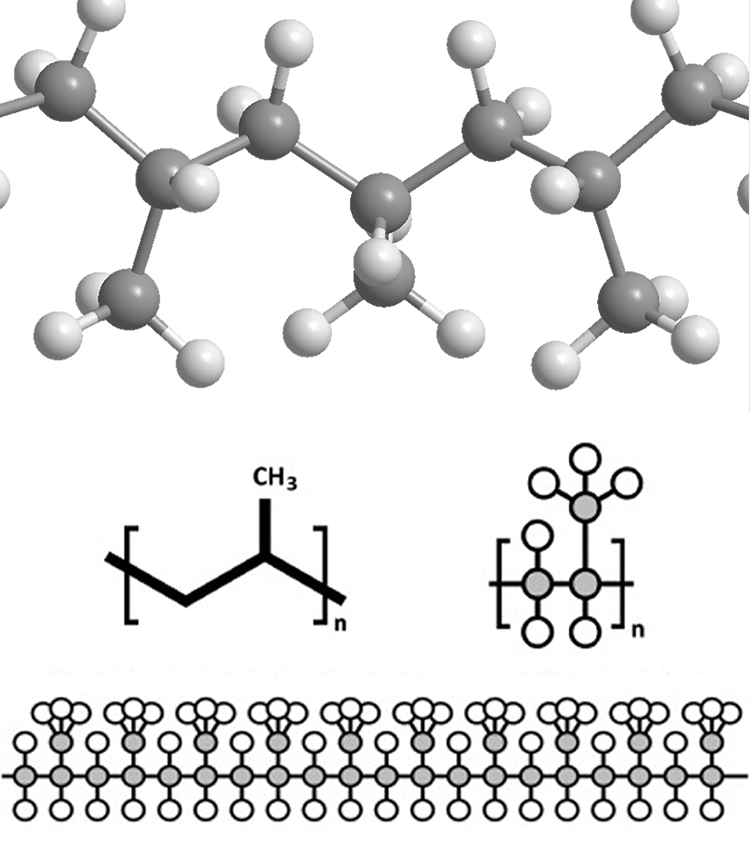

Polypropylene, often abbreviated as PP, is a thermoplastic polymer known for its stable molecular structure and resistance to many chemicals. In industrial applications, this material is valued not for extreme strength, but for consistency and predictability. Unlike softer plastics, PP maintains its shape under moderate pressure while remaining light in weight.

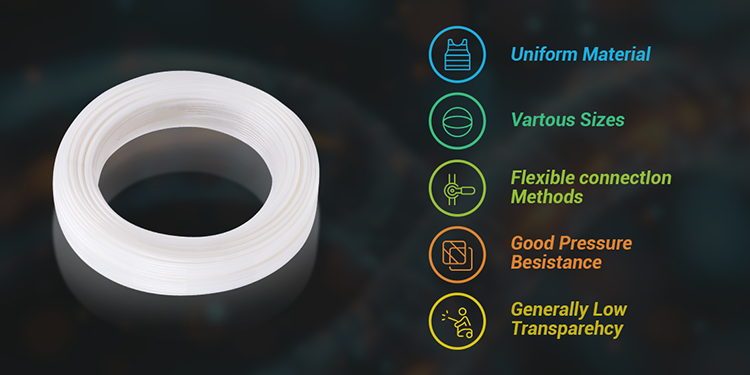

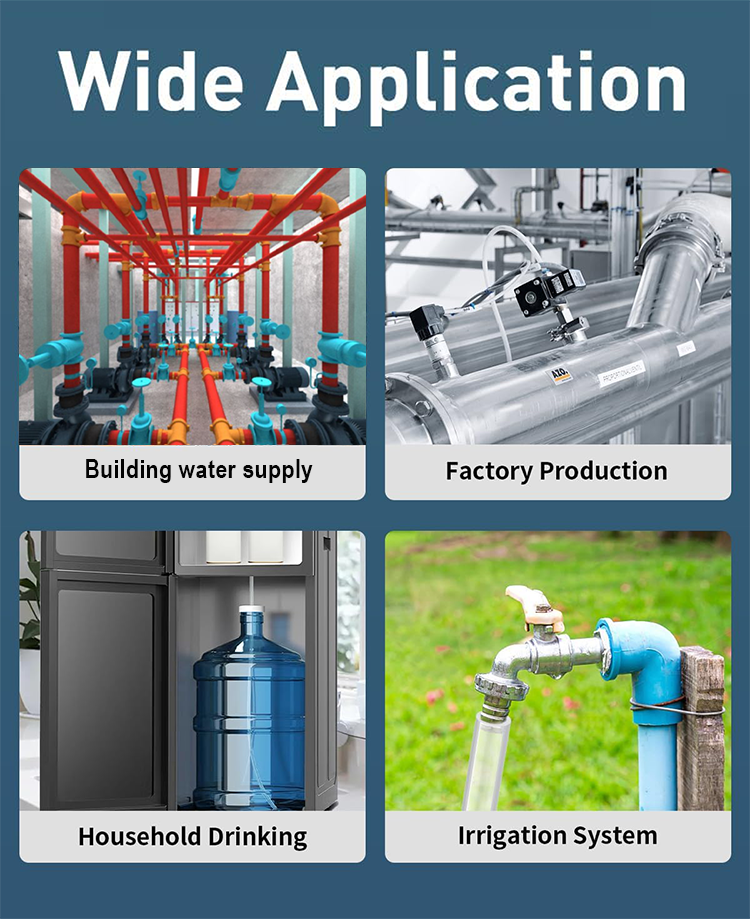

In pneumatic systems, polypropylene material is commonly processed into polypropylene tubes and hoses. These tubes are suitable for air, water, and a wide range of non-aggressive fluids. For factories that handle frequent media changes or cleaning cycles, PP offers a reliable middle ground between rigid plastics and elastomer hoses.

When selecting tubing, engineers often compare PP with PU, nylon (PA), and PVC. Each material has its place, but polypropylene tubing stands out in chemically sensitive environments. Compared with PU tubing, PP offers better resistance to acids and alkalis, although it is slightly less elastic. Compared with nylon, it absorbs less moisture and remains more dimensionally stable.

From a cost perspective, PP tube rolls are often more economical for large-scale installations. This makes them attractive to distributors and OEM customers who need consistent quality across long production runs. Material selection is rarely about “best overall,” but about “best fit for the application”.

One of the strongest advantages of polypropylene material is its chemical resistance. PP tubes perform well with most acids, alkalis, salts, and cleaning agents commonly used in industrial environments. This is why they are frequently used in chemical dosing systems, laboratory air lines, and fluid transfer applications.

In terms of temperature, polypropylene tubing typically operates reliably in a moderate range. While it is not designed for high-temperature steam, it maintains stability in normal pneumatic operating conditions. According to polymer material data from industry material databases, PP retains its mechanical properties better than many general-purpose plastics under continuous chemical exposure.

Although PP is not as elastic as polyurethane, PP flexible hose still offers sufficient bend radius for most pneumatic layouts. It resists kinking better than rigid plastic pipes and maintains a smooth internal surface, supporting stable airflow.

Installation efficiency is another reason PP tubing is widely used. Polypropylene tubes are compatible with standard push-in fittings and compression fittings, making them easy to cut, route, and replace. For maintenance teams, this translates into faster line changes and lower labor cost over time.

In real-world supply chains, pp tube roll packaging is often preferred over fixed-length tubes. Rolls reduce waste, simplify inventory management, and allow installers to cut exact lengths on site. This is especially valuable for distributors serving diverse customer requirements.

Straight-cut polypropylene tubing is still used in predefined assemblies or OEM equipment where consistency matters most. Choosing the right form is less about performance and more about logistics and installation efficiency, a consideration that procurement teams increasingly prioritize.

Polypropylene tubing is widely used across industries such as packaging machinery, water treatment equipment, chemical processing, and food-related auxiliary systems. While PP is not always in direct food contact, its clean surface and chemical stability make it suitable for peripheral pneumatic lines.

In automation systems, polypropylene tubes are often paired with valves, regulators, and cylinders where media cleanliness and material compatibility are more critical than extreme flexibility. This makes PP a practical choice for systems designed for long-term, low-maintenance operation.

Polypropylene tubing is not chosen for extremes—it is chosen for balance. Its combination of chemical resistance, installation convenience, and cost efficiency makes it a dependable option in many pneumatic applications. For engineers, buyers, and end users, understanding polypropylene material properties allows better system decisions and fewer surprises during operation.

In industrial systems, reliability often comes from well-matched components rather than complex design. Polypropylene tubes are a clear example of how the right material choice quietly supports long-term performance.

As a global pneumatic component supplier, FOKCA Automation provides polypropylene tubing and PP flexible hose designed for compatibility with common pneumatic fittings and systems. Our products are manufactured with stable material formulation, consistent dimensions, and controlled extrusion processes, ensuring predictable performance in real installations.

Beyond standard specifications, FOKCA supports OEM/ODM services, including custom colors, special diameters, and tailored packaging such as PP tube rolls. This flexibility helps distributors and equipment manufacturers adapt to different market standards while maintaining a unified supply source.

For more information on polyolefin tubings, please do not hesitate to Contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-Retardant

Sep 24, 2025 Blog

Can polyurethane tubing be used for fuel lines?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap