Dec 26, 2025

In industrial automation, “vacuum” is one of those terms that sounds simple but is often misunderstood in practice. Many users associate vacuum with the idea of “nothingness,” yet in reality, absolute vacuum does not exist in industrial applications. What engineers and equipment users work with every day is relative vacuum—a pressure condition lower than standard atmospheric pressure. Understanding this distinction is essential for selecting, designing, and operating reliable vacuum systems on automated production lines.

From pick-and-place robots to packaging machines and CNC handling systems, vacuum technology has become a core part of modern automation. We will explain what vacuum really means, how vacuum systems work, and why proper component selection directly impacts efficiency, stability, and cost control.

In physics, vacuum is defined as a space devoid of matter. However, in industrial automation, this ideal condition is neither achievable nor necessary. Any pressure lower than standard atmospheric pressure (101.325 kPa) is considered vacuum. The key is not whether air is completely absent, but how much lower the pressure is compared to the surrounding environment.

This is why vacuum strength is described using vacuum degree, often expressed as negative pressure (kPa, bar) or as a percentage of atmospheric pressure.

For example, a system operating at –60 kPa does not mean “no air,” but rather that the internal pressure is significantly lower than the outside atmosphere, creating a pressure difference that can be used to generate holding force.

In practical automation scenarios, this pressure difference is what allows vacuum cups to grip, lift, and move objects safely.

Vacuum degree is not just a number on a gauge; it directly determines whether a system can reliably handle a specific workpiece. A higher vacuum degree means a larger pressure difference, resulting in stronger suction force—but higher is not always better.

For example, lightweight cartons or plastic films often require only moderate vacuum levels. Excessive vacuum may deform the material or increase energy consumption unnecessarily. On the other hand, heavy metal sheets, glass panels, or uneven surfaces require higher vacuum degrees to maintain stable gripping during acceleration and deceleration.

From a system design perspective, the goal is to match vacuum degree with application requirements, balancing safety margin, response speed, and energy efficiency. This is where experienced component selection becomes more important than simply choosing the strongest vacuum source available.

A vacuum system is a functional assembly designed to generate, control, and apply vacuum for industrial tasks. In automation, its most common role is handling and positioning workpieces using vacuum suction rather than mechanical gripping.

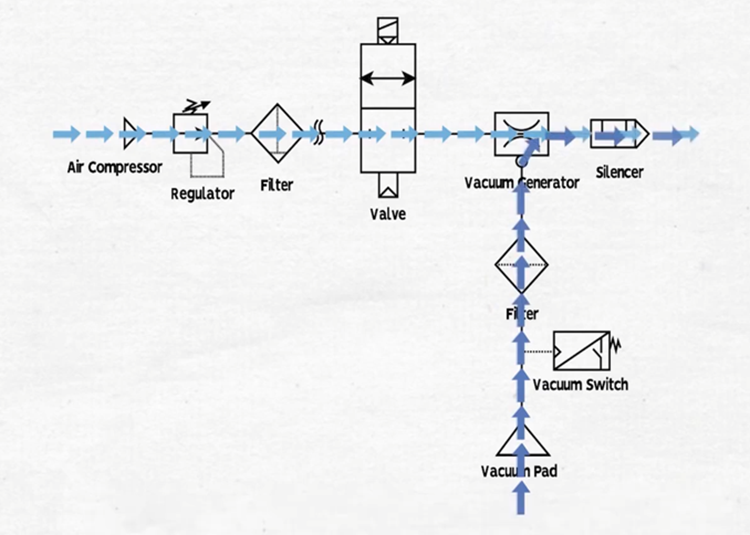

A typical industrial vacuum system consists of:

◆A vacuum generator (vacuum pump or ejector)

◆Vacuum suction cups

◆Control components such as valves and sensors

◆Optional filters and reservoirs

These components work together to create a stable vacuum environment that can respond quickly to control signals from PLCs or robotic controllers. In automated lines, vacuum systems are valued for their simplicity, speed, and adaptability to different product shapes.

The most visible part of any vacuum system is the suction cup. Its role is straightforward: create a sealed contact with the workpiece surface so that atmospheric pressure can press the object against the cup when internal pressure drops.

However, suction cup performance depends on several factors:

◆Surface roughness and porosity of the workpiece

◆Cup material (rubber, silicone, polyurethane)

◆Cup diameter and lip structure

◆Available vacuum degree and airflow

In real production environments, surfaces are rarely perfect. Dust, oil, or minor surface irregularities can reduce sealing performance. This is why vacuum systems must be designed with practical safety margins, not theoretical calculations alone.

Experienced automation suppliers often recommend combining proper cup selection with stable vacuum generation rather than relying on oversized pumps.

Industrial vacuum systems typically use one of two methods to generate vacuum: vacuum pumps or vacuum ejectors.

Vacuum pumps are suitable for applications requiring continuous vacuum and higher flow rates, such as large-format handling or centralized vacuum systems. They are often used in packaging lines or material handling systems with multiple suction points.

Vacuum ejectors, on the other hand, use compressed air to create vacuum via the Venturi effect. They are compact, fast-responding, and easy to integrate into decentralized automation setups. For many pick-and-place applications, ejectors provide an excellent balance between performance and installation simplicity.

In modern factories, energy efficiency is a growing concern. Choosing the right vacuum generation method—and matching it with correct control logic—can significantly reduce compressed air consumption.

Vacuum handling offers several advantages over mechanical gripping:

1.Non-damaging contact, ideal for fragile or finished surfaces

2.Simple mechanical structure with fewer moving parts

3.High-speed operation suitable for automation cycles

4.Easy adaptation to different product sizes and shapes

Because of these advantages, vacuum systems are widely used in electronics manufacturing, food packaging, glass handling, woodworking, and sheet metal processing. In many cases, switching from mechanical grippers to vacuum systems improves throughput while reducing maintenance requirements.

However, these benefits are only realized when system components are properly matched and installed.

Many vacuum-related issues in factories do not come from defective components, but from incomplete system understanding. Common problems include insufficient holding force, slow response times, unstable gripping, or excessive energy consumption.

These issues often trace back to:

1.Undersized or oversized vacuum generators

2.Inappropriate suction cup materials

3.Poor tubing layout causing pressure loss

4.Lack of filtration leading to contamination

From a procurement and engineering perspective, selecting vacuum components based solely on unit price often leads to higher long-term costs. A well-designed vacuum system should prioritize reliability, repeatability, and ease of maintenance.

For distributors, equipment engineers, and factory managers, vacuum system selection should always start from the application itself. Workpiece material, weight, surface condition, cycle time, and available utilities all influence the optimal configuration.

This is where working with a supplier that understands OEM and ODM requirements becomes valuable. Instead of offering isolated components, experienced suppliers can provide application-oriented recommendations, helping customers avoid trial-and-error during commissioning.

In automated lines, vacuum systems rarely operate alone. They must integrate smoothly with cylinders, valves, sensors, pneumatic tubing , fittings and control logic, forming a complete pneumatic solution.

As a global supplier of pneumatic components, FOKCA Automation provides more than individual parts. With extensive experience in OEM and ODM services, FOKCA supports customers in building stable, application-specific pneumatic and vacuum solutions.

From vacuum-compatiblevacuum generator, pneumatic tubing and fittings to control valves and actuators that work seamlessly with vacuum systems, FOKCA focuses on consistency, compatibility, and long-term performance. This approach is especially valuable for distributors and equipment manufacturers seeking standardized solutions across multiple projects.

By aligning component design with real industrial use cases, FOKCA helps customers reduce downtime, simplify sourcing, and improve system reliability.

Vacuum is not an abstract concept reserved for laboratories—it is a practical, measurable tool that drives efficiency in modern automation. Understanding that vacuum is defined by pressure difference, not absolute emptiness, allows engineers and decision-makers to design systems that are both effective and economical.

When vacuum systems are properly designed, they become one of the most reliable handling methods available. And when supported by well-matched pneumatic components, they contribute directly to productivity, quality stability, and operational safety across industries.

For automation professionals, mastering vacuum fundamentals is not optional—it is part of building systems that perform consistently in real-world conditions.

For more information or to place an order, feel free to contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-RetardantLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap