Dec 12, 2025

When industrial teams need to link two air hoses of different diameters, the first challenge is always reliability: Will the joint leak? Will the airflow drop? Will the connection survive continuous vibration? Choosing the right air hose quick connect system — and preparing the tube ends correctly — determines whether the installation runs smoothly or becomes a maintenance issue.

PU-series connectors, including PG, BPU, and SPU types, offer a proven and efficient solution for distributors, equipment engineers, purchasing managers, and factory end-users who need stable hose connections in pneumatic applications.

When hoses of different OD/ID sizes must be linked, many factories still rely on clamps, threaded joints, or customized adapters. These older methods are slow, leak-prone, and require tools.

A modern air hose quick connect provides:

◆Instant push-in assembly without tools

◆Secure sealing even with pressure fluctuations

◆Compatibility with PU, PE, and Nylon hoses

◆Lower maintenance cost for distributors and plant operators

◆Compact size for tight installation spaces

For teams managing multiple machine models or mixed pneumatic systems, a versatile push-in connector eliminates training complexity and reduces spare-part inventory.

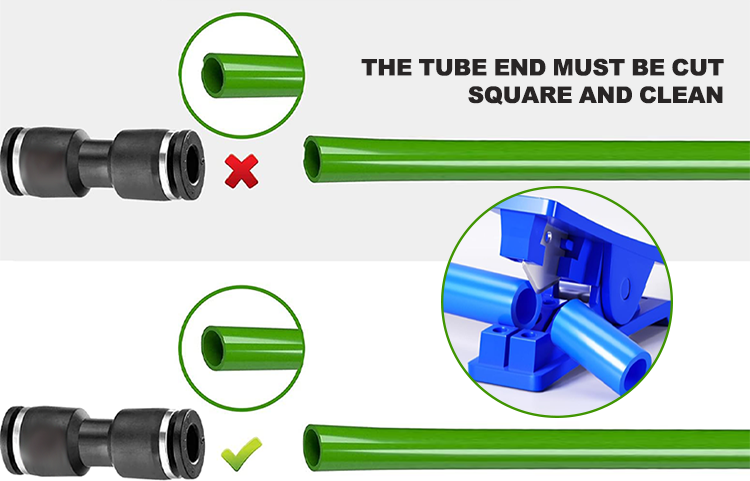

Before inserting the hose into any PG, BPU, or SPU connector, the tube end must be cut square and clean.

A poorly cut hose leads to:

◆Micro-leakage

◆Incomplete sealing

◆Reduced pull-out resistance

◆Higher chances of vibration loosening

Best practice: always use a tube cutter for a flat, burr-free, perpendicular cut.

This single step improves sealing reliability by up to 25% (based on general pneumatic component testing data from industry reports).

Below is a simplified view of the three connector families used for air hose quick connect solutions:

Connector Type | Typical Use Case | Key Strength | Common Hose Sizes | Notes |

PG Series | Hose-to-hose joints (equal or step-down sizes) | Strong grip + compact | 4–16 mm | Ideal for two-way hose extensions |

BPU Series | Mixed-diameter connections | Flexible size combinations | 4–12 mm | Good for portable tools & field repair |

SPU Series | High-flow or continuous vibration environments | Enhanced sealing | 6–16 mm | Used in automation & production lines |

These PU-series connectors are widely used in packaging machines, textile equipment, food automation, woodworking systems, assembly lines, and general pneumatic tools.

PG connectors are the simplest and most robust option when technicians need a two hose connector for everyday pneumatic applications.

Where PG Connectors Perform Best

◆Linking two hoses of the same diameter

◆Creating temporary or permanent extensions

◆Upgrading old hose sections without replacing entire lines

◆Adding branches via T-type PG fittings (optional models)

Their internal stainless-steel collet ensures a firm mechanical lock, while the PU body provides corrosion resistance and lightweight installation — advantages highly valued by distributors who sell to multi-industry clients.

Why PG Is Ideal for Quick Repairs

The push-to-connect structure makes PG fittings ideal for:

◆On-site repairs

◆Machine adjustments

◆Temporary setups during testing

Technicians can perform hose assembly within seconds, without tools or thread sealants.

When two tubes do not share the same size, a standard coupler cannot guarantee sealing. This is why the BPU series exists.

Why BPU Fits Mixed-Diameter Applications

The BPU connector’s internal design accommodates size transitions such as:

◆6 mm → 8 mm

◆8 mm → 10 mm

◆4 mm → 6 mm

This helps factories upgrade equipment gradually without needing to replace entire hose networks.

Typical Industry Scenarios

◆Switching from old 1/4”lines to metric hoses

◆Adding new pneumatic modules with different air consumption

◆Tooling systems that use mixed hose sizes for different actuators

With a BPU connector, teams maintain full airflow and stable pressure while avoiding the cost of redesigning or re-plumbing the system.

SPU connectors are engineered for demanding situations where vibration, flow rate, or long operating cycles require a stronger air hose quick connection.

When SPU Makes a Difference

◆Robotic arms

◆Automatic packaging lines

◆Long-cycle repetitive motion

◆High-precision pneumatic drives

The design includes a reinforced sealing ring and a more stable collet structure, giving users:

◆Higher leak resistance

◆Better performance under constant vibration

◆Longer connector service life

For equipment engineers responsible for uptime, SPU provides a strong balance between durability and installation efficiency.

A packaging factory needs to link a 10 mm air line from the main compressor to a 6 mm hose feeding a pneumatic cylinder.

The engineer chooses a BPU 10–6 quick connector.

Steps:

Cut both hose ends flat and clean.

Insert the 10 mm hose until it clicks.

Insert the 6 mm hose on the opposite side.

Perform a short pressure test.

Result: stable flow, no leakage, installation completed in under 60 seconds.

This workflow is typical when operators need fast changeovers with minimal downtime.

To increase conversion for distributors and technical buyers, the following competitive advantages can be highlighted:

1. High Precision Molding

All FOKCA PU connectors are manufactured with high-precision tooling, ensuring:

◆Smooth insertion

◆Consistent sealing

◆Reduced internal turbulence

This leads to more stable airflow, especially important for automation systems.

2. Reliable Stainless-Steel Clamps

The internal clamp uses 304 stainless steel, offering stronger bite and longer lifespan than common lower-grade steel used by some low-cost competitors.

3. Full Size Coverage

From 4 mm to 16 mm, FOKCA supports nearly all mainstream pneumatic hoses, reducing inventory burden for distributors.

4. Multi-Environment Compatibility

PU connectors maintain stable performance across:

◆High humidity

◆Oily air

◆Temperature fluctuations

This reliability makes them suitable for OEMs selling to multi-industry customers.

5. Fast Supply for Distributors

FOKCA’s stable stock and production efficiency help distributors shorten lead time and win more repeat customers.

These specs align with typical industrial pneumatic standards referenced in general market analyses.

When connecting two hoses of different diameters, the fastest, cleanest, and most reliable method is choosing the appropriate air hose quick connect model from the PU series.

Engineers gain stability and easy installation; distributors gain repeat sales; purchasing teams get lower lifecycle costs.

A cleanly cut hose end + the right connector = a long-lasting pneumatic joint.

For more information on polyolefin tubings, please do not hesitate to Contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic SystemsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap