Dec 29, 2025

In automated handling systems, the choice between a vacuum pump and a vacuum generator is rarely a purely technical debate. It affects energy consumption, system layout, response speed, maintenance cost, and even how reliably a production line can run over multiple shifts. For distributors, equipment engineers, and factory managers, understanding the real difference between these two vacuum sources helps avoid overdesign—or worse, underperformance—later in the project.

At a glance, both devices create vacuum. In practice, they serve very different roles.

A vacuum pump works much like an industrial vacuum cleaner. It is usually motor-driven, relatively large in size, and designed to generate strong and stable vacuum levels over long periods of time. Once started, it can maintain suction continuously without frequent on–off cycling.

This makes vacuum pumps a natural choice for applications that require uninterrupted vacuum, such as vacuum clamping, large-area material holding, or centralized vacuum systems serving multiple workstations. In woodworking or glass processing, for example, a vacuum pump can hold heavy or oversized workpieces in place for extended durations without noticeable performance loss.

The trade-off is cost and complexity. Vacuum pumps are more expensive, consume more energy, and require scheduled maintenance. They also occupy more installation space, which can be a limitation in compact machines or modular production lines.

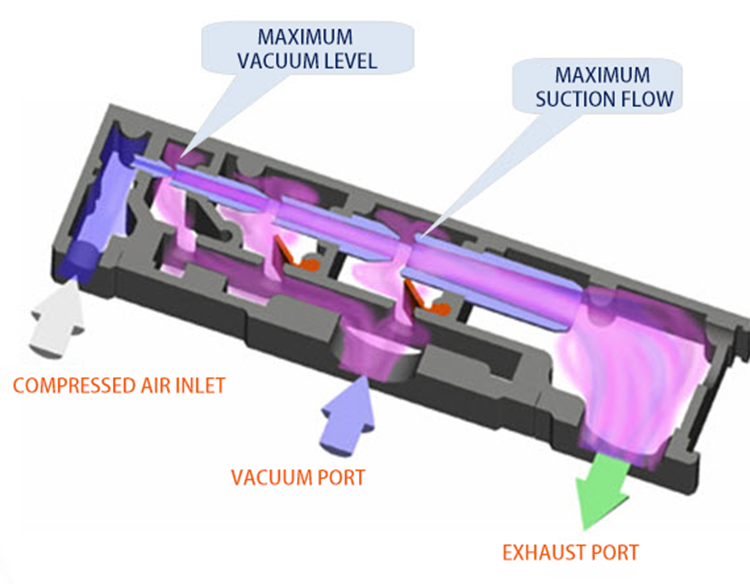

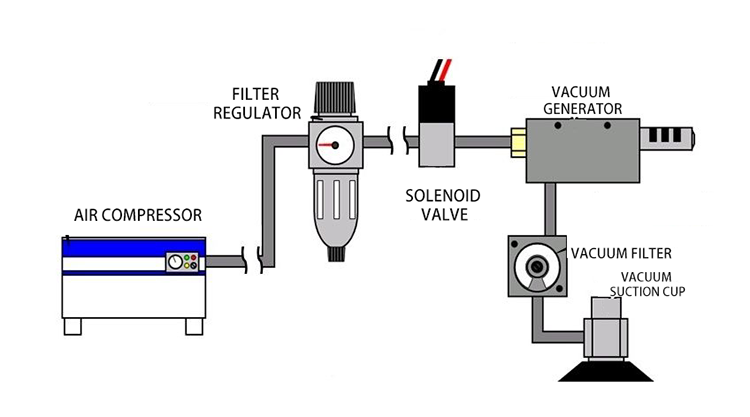

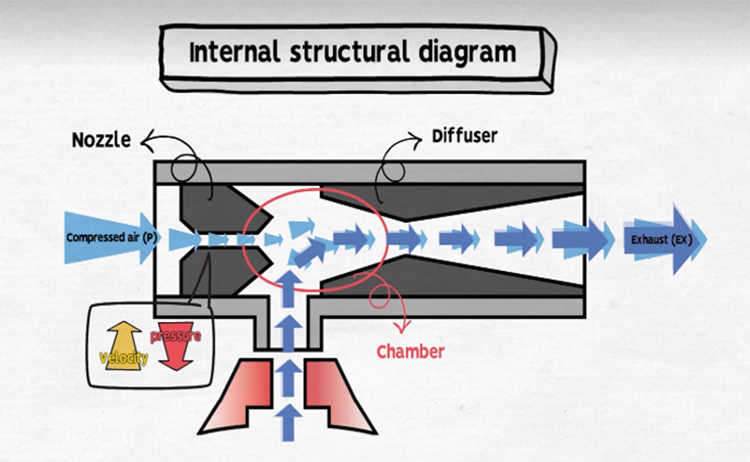

A vacuum generator, often referred to as a pneumatic vacuum generator, creates vacuum using compressed air based on the Venturi principle. Compared with a pump, it is small, lightweight, and relatively inexpensive, which explains why it is widely used in pick-and-place automation.

In applications where suction cups repeatedly grip and release workpieces—such as packaging, electronics assembly, or robotic handling—a vacuum generator excels. It can be switched on and off rapidly, synchronizing perfectly with machine cycles. This responsiveness is a key reason why SMC vacuum generators and similar designs dominate high-speed automation lines.

However, the vacuum level produced by a generator is typically weaker than that of a pump. It is optimized for intermittent operation rather than continuous suction, making it less suitable for holding large loads over long periods.

The fundamental reason these two solutions differ lies in how they create vacuum. A vacuum pump physically moves air using mechanical components, allowing it to sustain vacuum regardless of cycle frequency. A vacuum generator, by contrast, relies on compressed air flow to create negative pressure locally.

This difference explains why generators are compact and low-cost, yet dependent on the availability and quality of compressed air. In factories with stable air supply, a pneumatic vacuum generator integrates seamlessly into existing pneumatic systems. Where compressed air is limited or expensive, a centralized vacuum pump may be more economical in the long run.

Industry energy studies often point out that compressed air is one of the most costly utilities in manufacturing. From a purchasing perspective, evaluating air consumption versus electrical power usage becomes an essential part of the selection process.

In carton handling and palletizing, vacuum generators are often mounted close to suction cups. This short air path improves response time and reduces system inertia. The generator only activates when a carton is picked, then shuts off immediately, conserving energy during idle phases.

In contrast, vacuum pumps dominate applications like vacuum tables, laminating machines, or material holding fixtures. These processes demand constant vacuum stability, where even minor fluctuations could affect product quality or safety.

Many modern factories actually combine both technologies. A centralized vacuum pump handles base-level holding tasks, while localized vacuum generators manage fast pick-and-place movements. This hybrid approach balances performance, cost, and flexibility.

1.Duty Cycle and Operating Pattern

If the vacuum source must run continuously for hours, a vacuum pump is usually the safer choice. For frequent start–stop cycles synchronized with machine motion, a vacuum generator offers better efficiency and responsiveness.

2.Required Vacuum Level and Flow Rate

Heavy or porous materials often require higher vacuum strength, favoring pumps. Lightweight, non-porous parts such as plastic trays or electronic components are well within the capability of SMC vacuum generators or equivalent designs.

3.Energy Consumption and Infrastructure

Compressed air availability plays a decisive role. Facilities with robust pneumatic infrastructure naturally lean toward pneumatic vacuum generators, while sites focused on electrical efficiency may prefer vacuum pumps.

4.Installation Space and System Design

Compact machines benefit from the small footprint of vacuum generators. Larger installations with centralized control rooms can accommodate vacuum pumps more easily.

5.A Practical Comparison at a Glance

Aspect | Vacuum Pump | Vacuum Generator |

Size | Large | Compact |

Initial Cost | High | Low |

Vacuum Strength | Strong | Moderate |

Operation Mode | Continuous | Intermittent / Cyclic |

Typical Use | Holding, clamping | Pick-and-place, handling |

Data based on common industrial configurations and market analysis reports from automation equipment suppliers.

SMC vacuum generators are widely recognized for their compact integration, stable performance, and broad model range. They are frequently selected by OEMs designing standardized automation modules. Their popularity also reflects a broader industry trend toward decentralized vacuum generation close to the point of use.

For distributors and system integrators, offering compatible alternatives with similar performance characteristics can be a strategic advantage, especially when lead time flexibility and customization are required.

As a global pneumatic components supplier, FOKCA Automation provides both standard and customized solutions for vacuum generators and vacuum-related components, supporting OEM and ODM projects worldwide. Beyond product supply, FOKCA assists customers in evaluating application parameters such as cycle time, air consumption, and load characteristics.

For distributors and purchasing managers, this translates into cost-effective alternatives to mainstream brands, consistent quality control, and the ability to tailor specifications for specific machines or markets. For equipment engineers, it means technical support that aligns component selection with real operating conditions rather than catalog assumptions.

Choosing between a vacuum pump and a vacuum generator is less about which technology is “better” and more about which fits the application. Pumps deliver endurance and strength, much like a powerful industrial vacuum cleaner. Vacuum generators offer speed, compactness, and economic efficiency for repetitive handling tasks.

When selected correctly, either solution can run reliably for years. When mismatched, even the most advanced automation system can suffer from unstable cycles, rising energy costs, or frequent maintenance. Understanding these differences upfront allows manufacturers to design systems that are not only functional, but genuinely efficient and scalable over time.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap