Dec 26, 2025

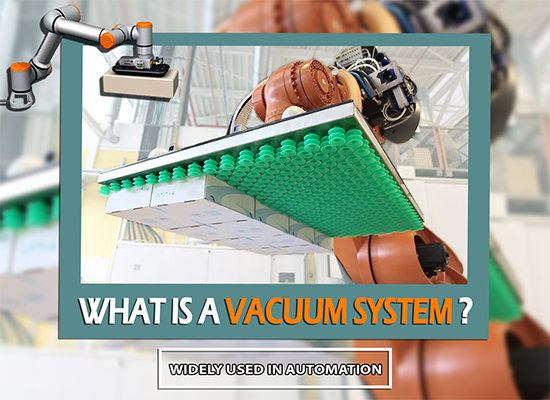

In industrial automation, vacuum generators are often small components with a disproportionately large impact. When a pick-and-place system fails, packaging lines slow down, or suction becomes unstable, the root cause frequently traces back to how the vacuum generator is selected, installed, or understood. Despite their compact size, vacuum generators sit at the center of many automated handling systems, especially in high-speed and flexible production environments.

Among global suppliers, SMC vacuum generator solutions are widely recognized for their modularity and reliability. Understanding how these devices work—and how different series such as ZU, ZH, and EV are applied—helps engineers, buyers, and distributors make decisions that balance performance, energy use, and long-term system stability.

A vacuum generator converts compressed air into vacuum using fluid dynamics rather than mechanical motion. Unlike a traditional vacuum generator pump with rotating parts, most pneumatic vacuum generators rely on the Venturi effect, which allows them to produce vacuum instantly and reliably with minimal maintenance.

In automation systems, vacuum generators are primarily used to:

◆Create vacuum for suction cups

◆Enable fast pick-and-place cycles

◆Reduce mechanical gripping complexity

◆Handle fragile or irregularly shaped products

Because they are air-driven, vacuum generators integrate naturally with pneumatic systems already using cylinders, valves, and air preparation units.

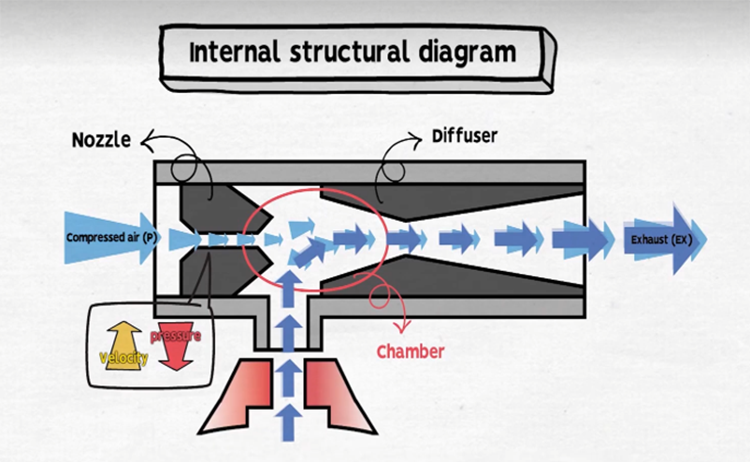

The vacuum generator working principle is based on a well-known physical phenomenon. When compressed air passes through a narrow nozzle at high speed, static pressure drops. This pressure drop creates a vacuum zone that draws in surrounding air through a vacuum port.

In practical terms:

a. Compressed air enters the generator

b. Air accelerates through an internal nozzle

c. Pressure decreases at the vacuum port

d. Surrounding air is drawn in, creating vacuum

e. Exhaust air exits through a silencer or muffler

This process happens almost instantaneously, which is why vacuum generators are preferred in high-cycle automation where response time matters more than continuous vacuum flow.

In many automation scenarios, a centralized vacuum generator pump may appear powerful but introduces complexity. Long piping runs, pressure losses, delayed response, and higher maintenance are common challenges.

By contrast, pneumatic vacuum generators offer:

1.Compact size, mountable close to suction cups

2.Fast on/off response

3.Minimal maintenance due to no moving parts

4.Easy integration with solenoid valves

5.Flexible scaling for multi-station systems

For decentralized automation cells, vacuum generators reduce system inertia and improve cycle consistency.

Different applications require different vacuum characteristics. This is why SMC vacuum generator designs are offered in multiple series, each optimized for specific conditions.

The ZU series is known for compact design and energy efficiency, making it suitable for small pick-and-place units and electronics handling.

The ZH series focuses on higher vacuum flow and holding force, often used for larger surfaces or porous materials.

The EV series integrates vacuum generation with control functions, reducing external piping and simplifying installation.

Choosing the correct series is less about brand preference and more about matching vacuum performance to application realities.

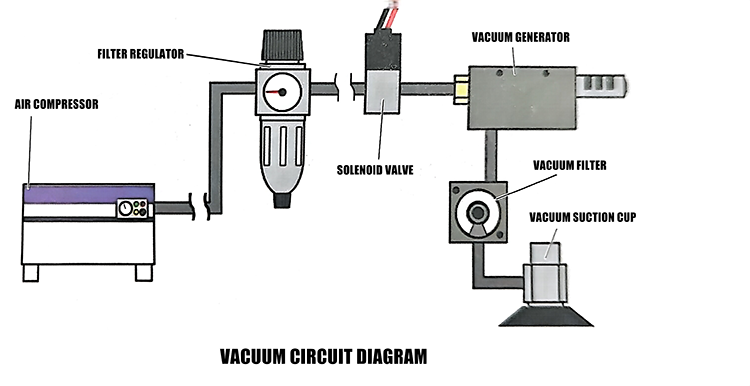

A vacuum generator rarely operates alone. In most systems, it works alongside a vacuum generator valve, typically a solenoid valve that controls air supply and release timing.

Proper valve integration enables:

◆Rapid vacuum build-up

◆Controlled blow-off for part release

◆Reduced compressed air consumption

◆Synchronization with PLC logic

In advanced systems, vacuum sensors provide feedback to ensure sufficient vacuum is achieved before movement continues, improving safety and repeatability.

Vacuum generators perform best when matched with compatible pneumatic components. Tubing diameter, fitting quality, air filtration, and pressure regulation all influence vacuum stability.

A poorly matched system may show adequate vacuum at startup but degrade under continuous operation. This is why system-level thinking matters more than isolated component selection.

As a global pneumatic component supplier, FOKCA Automation supports customers beyond individual part supply. With extensive OEM and ODM experience, FOKCA helps distributors, machine builders, and end users integrate vacuum generators into reliable pneumatic systems.

By offering compatible cylinders, solenoid valves, air preparation units, pneumatic tubing ,fittings, and quick couplings, FOKCA ensures that vacuum generators operate within stable and predictable conditions. Customization options allow adaptation to space constraints, environmental requirements, and specific automation layouts.

This system-oriented approach reduces commissioning time and improves long-term performance across multiple equipment platforms.

Vacuum generators are not just accessories; they are enabling components that allow automation systems to move faster, handle more delicately, and adapt to product variation. Understanding how they work, how they are controlled, and how they integrate with the broader pneumatic architecture leads to better engineering outcomes and smarter purchasing decisions.

When vacuum generators are selected based on application logic rather than habit or price alone, they contribute directly to uptime, energy efficiency, and production consistency.

For more information or to place an order, feel free to contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-Retardant

Sep 24, 2025 Blog

Can polyurethane tubing be used for fuel lines?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap