Dec 15, 2025

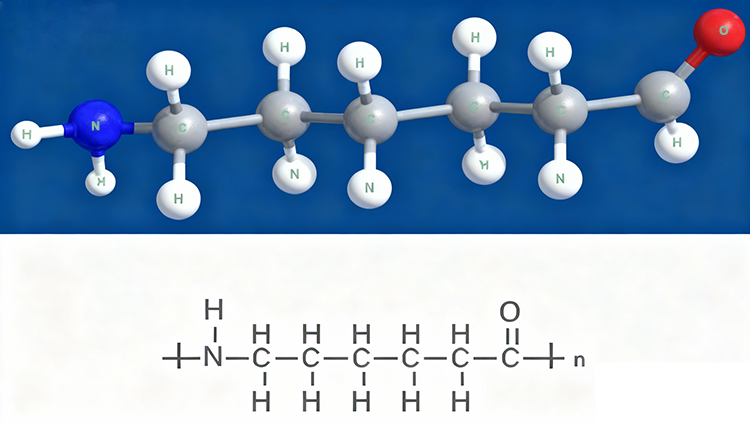

Nylon 6, or PA6, has long held its place as the backbone of the nylon family. Unlike specialized nylons that excel in one particular property, PA6 is renowned for its balanced performance across mechanical, thermal, and chemical characteristics. This equilibrium makes it an ideal choice for a wide range of applications where high performance is desired without demanding specialized material features. In fact, PA6 accounts for approximately 55% of the nylon market, establishing itself as the most widely used and cost-effective nylon material for industrial tubing solutions.

The true strength of PA6 lies in its versatility. It may not boast the extreme flexibility of PA11 or the chemical resistance of PA12, but it achieves consistent, reliable performance in most operational environments. Its key properties include:

Property | PA6 Performance | Notes |

Tensile Strength | 70–90 MPa | Strong enough for general pneumatic and hydraulic tubing |

Elongation at Break | 20–50% | Offers moderate flexibility, reduces risk of cracking |

Abrasion Resistance | High | Suitable for repeated mechanical movement |

Chemical Resistance | Moderate | Compatible with common oils, greases, and mild chemicals |

Operating Temperature | -40°C to +120°C | Ideal for general machinery environments |

This balance makes PA6 particularly appealing for plastic tubing, air tubing, and hose plastic applications where a combination of durability, flexibility, and affordability is required.

For many industrial applications, extreme material properties are unnecessary. What is essential is a material that performs reliably while remaining cost-effective. PA6 hits this sweet spot, offering excellent performance-to-price ratio.

Example: A mid-sized manufacturing plant replacing specialized PA12 tubing with PA6 saw a 20% reduction in material cost without affecting operational efficiency. Such adaptability has contributed to PA6's dominance in industrial tubing, particularly for plastic tubing used in pneumatic systems and general machinery applications.

Its widespread use in industries like automation, packaging, and robotics underscores its reputation as a “default nylon” that engineers and procurement teams trust.

PA6 tubing is commonly applied in environments where moderate mechanical performance and chemical resistance suffice. Typical applications include:

1.Pneumatic systems: Air tubing for actuators, valves, and cylinders

2.Hydraulic auxiliary lines: Low-pressure fluid transfer in machinery

3.Mechanical equipment: Protective sheaths, conduit for wires, or lightweight connectors

Case Study: A European automation equipment provider integrated PA6 nylon tubing across its pneumatic modules. The tubing’s flexibility, durability, and chemical compatibility ensured smooth operation, while its affordability allowed the company to standardize components across multiple product lines, simplifying inventory management.

These examples highlight how PA6’s balanced characteristics translate into practical advantages, reducing the need for material specialization unless the application has extreme requirements.

At FOKCA, our PA6 plastic tubing, nylon tubing, and air tubing stand out for quality, consistency, and service. Our advantages include:

◆Global OEM/ODM capabilities: Customized tubing solutions tailored to client specifications

◆High-quality raw materials: Ensures uniform mechanical properties, chemical resistance, and dimensional accuracy

◆Rapid delivery and stable supply: Supporting distributors, OEMs, and industrial end-users

◆Wide range of specifications: Available in various diameters, wall thicknesses, colors, and temperature ratings

By choosing FOKCA, customers can simplify procurement, reduce lead times, and ensure long-term operational reliability.

Choosing the right PA6 tubingrequires attention to diameter, wall thickness, and temperature tolerance. For pneumatic applications, ensure tubing matches the working pressure of your system. While PA6 tolerates moderate chemicals, avoid prolonged exposure to strong acids or bases, which may degrade the material over time.

Maintenance tip: Regularly inspect tubing for wear or discoloration, especially in high-friction or high-temperature environments. FOKCA’s tubing, with its consistent quality, reduces the likelihood of premature failure, ensuring your machinery runs smoothly.

PA6 remains the most balanced and versatile nylon for industrial applications, offering a unique combination of performance, reliability, and cost-effectiveness. Its wide adoption across pneumatic systems, air tubing, and plastic tubing solutions is a testament to its practical value.

For engineers, distributors, and procurement managers seeking high-quality, reliable, and cost-effective PA6 tubing, FOKCA provides premium solutions that integrate seamlessly into industrial and automation workflows. Whether it’s standard air tubing or custom OEM applications, PA6’s balanced properties make it the go-to choice in the nylon family.

For more detail you can contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic FittingsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap