Jan 04, 2026

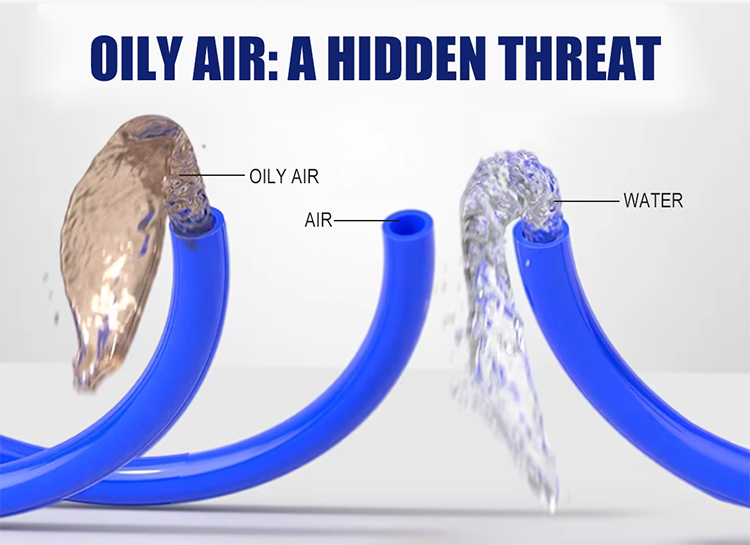

Polyurethane (PU) tubing is a staple in pneumatic systems due to its flexibility, ease of routing, and abrasion resistance. However, even high-quality PU tubing can degrade prematurely when exposed to oily compressed air—a factor often overlooked by distributors, engineers, and procurement managers. Understanding this interaction helps prevent air leaks, downtime, and unnecessary replacements.

Compressed air is rarely completely clean. Many industrial compressors, especially piston or screw types, release residual oil aerosols into the air line. Over time, this oil can reach PU tubing, valves, and fittings. Even when systems meet standard air quality levels (ISO 8573-1 Class 2–4 for oil), long-term exposure can compromise tube integrity. Subtle effects may go unnoticed initially, but they reduce the material’s lifespan.

PU’s molecular structure provides elasticity and abrasion resistance, but it is sensitive to mineral oils and compressor lubricants. Prolonged contact may cause softening, wall swelling, and reduced tensile strength, which often shows up near fittings or bend points. The tubing may still hold pressure temporarily, but cracks and leaks eventually appear.

For engineers and distributors, recognizing this chemical compatibility issue is crucial in guiding clients toward reliable solutions.

Field reports show that PU tubing exposed to continuous oil mist can experience 30–50% shorter service life compared with dry air systems. Oil acts as a plasticizer: the tube initially becomes softer, but over time this flexibility turns into instability. Micro-cracks form, fittings lose grip, and leaks occur, especially in high-cycle automation environments.

Proactive maintenance can prevent failures. Common early warning signs include:

◆Tubing feels unusually soft or sticky

◆Surface appears glossy or slightly swollen

◆Push-in fittings lose retention strength

◆Small leaks appear near high-pressure zones

Detecting these signs allows technicians to replace tubing before major downtime or safety issues arise.

Mitigating oil damage starts with air preparation. Multi-stage filters and oil separators reduce oil aerosol concentration, protecting PU tubing and improving overall system reliability. For systems with continuous oil-lubricated air, alternative materials like PA tubing or oil-resistant PU can provide longer-lasting performance.

FOKCA offers optimized PU tubing formulations that resist common compressor oils while maintaining flexibility and reliable sealing in push-in fittings. Combined with precision dimensions and quality control, FOKCA tubing helps distributors, engineers, and factory operators reduce downtime and maintenance costs.

When advising customers, these questions ensure correct tube selection:

Is the compressed air oil-lubricated?

What is the system’s duty cycle—intermittent or continuous?

Are high-temperature zones present near valves or cylinders?

How regularly is air filtration maintained?

Answering these guides material choice and installation recommendations, positioning distributors and engineers as trusted technical partners rather than just product suppliers.

FOKCA’s PU tubing and push-in fittings are designed with real-world air quality in mind. The material resists common oils, maintains elastic recovery, and ensures strong, leak-free connections even under demanding conditions. For distributors, OEMs, and end users, this combination of material expertise, precision fittings, and application support translates into longer-lasting pneumatic systems and fewer service interruptions.

Oily compressed air doesn’t immediately destroy PU tubing, but it significantly accelerates aging if left unaddressed. By combining proper air preparation, careful material selection, and high-quality fittings like those from FOKCA, distributors, engineers, and factory managers can extend tube life, reduce air leaks, and improve system reliability—all while maintaining efficient operations and lowering long-term costs.

If you have any requirements or questions,please feel free to Contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap