Jan 06, 2026

In pneumatic and fluid systems, few things cause more confusion than identifying an unknown thread. A fitting looks familiar, it screws in “almost right,” but leaks appear after installation. In many real cases, the root cause is simple: the thread size or standard was guessed instead of measured. This happens often with NPT fittings , especially when the part is removed from existing equipment or comes without documentation.

If you have an NPT fitting in hand and need to know exactly what size it is, there are two reliable approaches. One is the most accurate professional method using thread gauges. The other is a practical field method using a caliper and a reference chart. Understanding both helps engineers, distributors, and buyers avoid mismatches, downtime, and unnecessary returns.

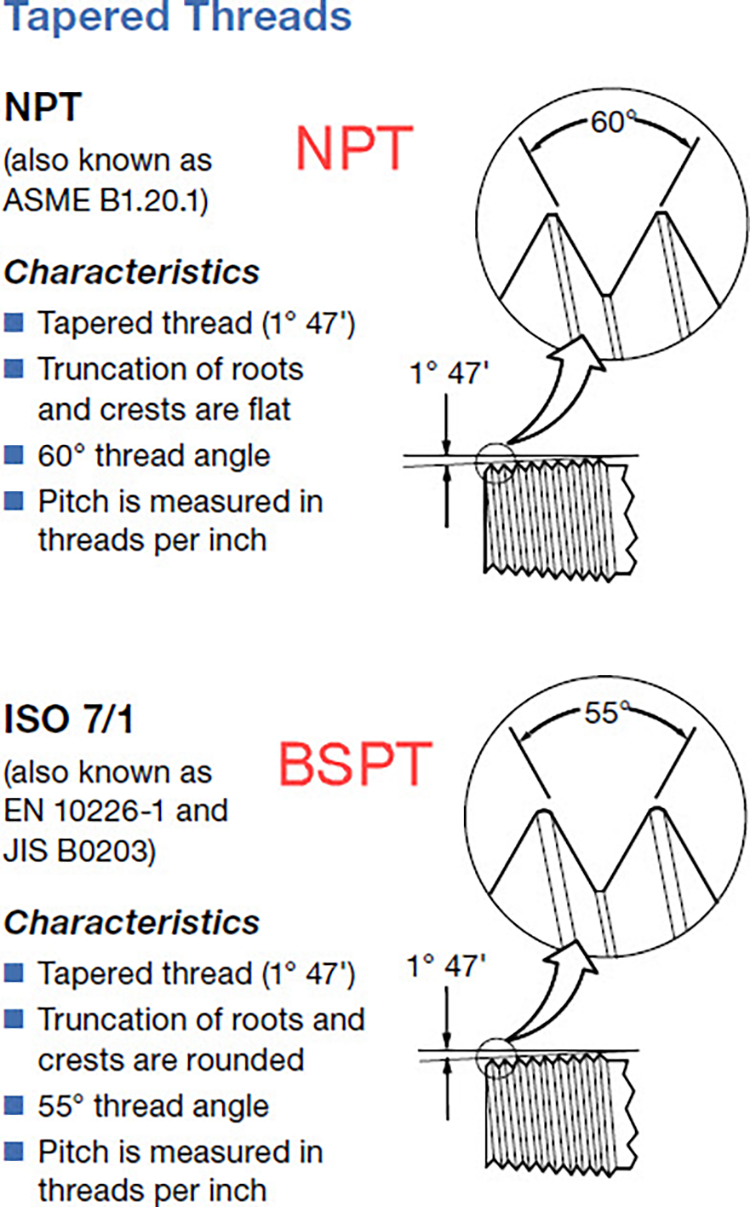

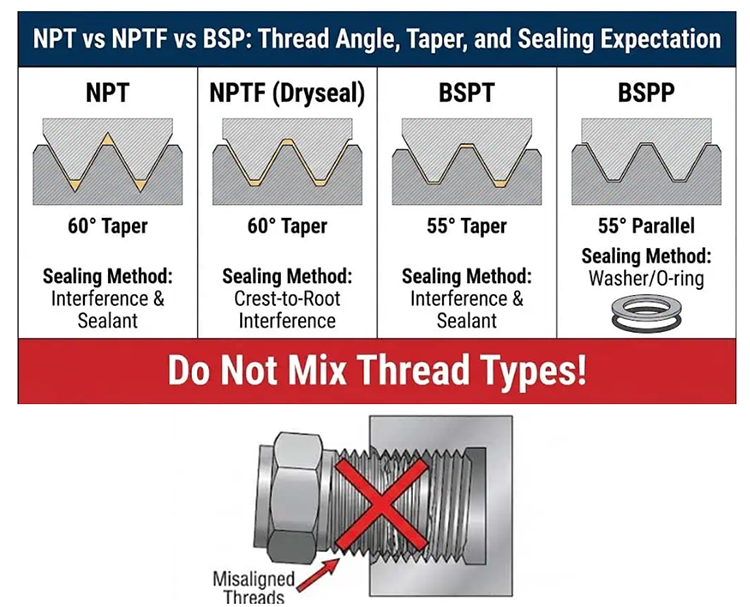

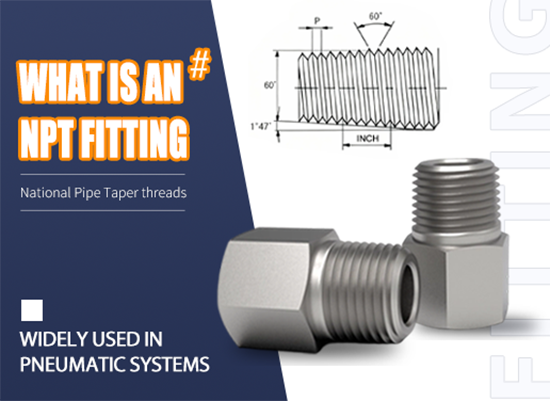

Before measuring anything, it’s important to understand what you’re dealing with. NPT (National Pipe Taper) threads are designed to seal through metal-to-metal interference, not by a flat gasket or O-ring. The thread has a 1:16 taper, meaning the diameter changes along the length.

This taper is the main reason NPT threads are often misidentified. A 1/4" NPT thread does not measure 1/4 inch anywhere on the fitting. Instead, its nominal size comes from historical pipe dimensions, not physical measurements. Engineers who assume “measure the outside diameter and read the size” often end up selecting the wrong fitting.

In pneumatic systems, even a small mismatch between NPT and BSPT or metric threads can cause slow leaks that are hard to trace.

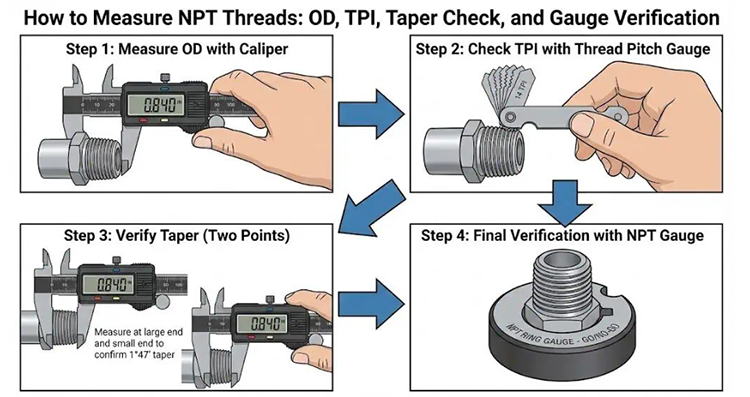

When accuracy matters — especially for OEM production, replacement parts, or bulk purchasing — a thread gauge is the correct tool. This is the same method used by manufacturers and quality inspectors.

A complete NPT thread gauge set includes two parts:

1.A pitch gauge to identify threads per inch (TPI)

2.A taper plug or ring gauge to confirm the NPT standard

To measure, start by matching the pitch gauge teeth to the thread profile. NPT threads commonly use 27, 18, 14, or 11.5 TPI, depending on size. When the gauge fits cleanly with no light gaps, you’ve identified the pitch.

Next, use the taper gauge to confirm the thread angle and taper. This step ensures you are not confusing NPT with BSPT, which has a similar taper but a different thread angle (55° vs 60°).

This method is the most reliable, especially for distributors handling mixed inventories or engineers specifying fittings for critical systems.

Not everyone has a thread gauge at hand. In maintenance rooms, warehouses, or on-site troubleshooting, a caliper and a reference table can still give dependable results — if done correctly.

First, use the caliper to measure the outside diameter (OD) of the male thread at the widest point. Because NPT is tapered, always measure near the first full thread. Record the value in millimeters or inches.

Second, measure the thread pitch by counting how many threads appear within one inch, or by measuring the distance between multiple threads and calculating the pitch. This step requires patience but improves accuracy significantly.

Once you have OD and pitch, compare the values with a standard NPT thread size chart. If both match one size range, you can be confident in your identification.

This method is widely used by equipment engineers when reverse-engineering existing pneumatic or hydraulic systems.

The table below shows commonly used NPT sizes in pneumatic systems. Values are approximate and intended for identification, not machining.

| Nominal Size | Threads per Inch | Approx. Male OD |

|---|---|---|

| 1/8" NPT | 27 TPI | ~10.3 mm |

| 1/4" NPT | 18 TPI | ~13.7 mm |

| 3/8" NPT | 18 TPI | ~17.1 mm |

| 1/2" NPT | 14 TPI | ~21.3 mm |

| 3/4" NPT | 14 TPI | ~26.7 mm |

| 1" NPT | 11.5 TPI | ~33.4 mm |

Data based on ASME B1.20.1 pipe thread standards.

When OD and TPI both align with one row, you’ve likely found the correct NPT size.

One frequent mistake is confusing NPT with BSPT. The threads may engage for a few turns, giving a false sense of compatibility, but the seal will be unreliable. Another error is assuming metric threads are “close enough” in low-pressure systems. Over time, vibration and pressure cycles expose these shortcuts.

Another issue arises when fittings are plated or coated. Surface treatments can slightly change measured diameters, which is why pitch measurement is just as important as diameter.

Experienced distributors often keep a small thread gauge set at the counter — not as a luxury, but as a cost-saving tool that prevents returns and customer complaints.

In compressed air systems, leaks are silent efficiency killers. Industry audits consistently show that 10–30% of compressed air is lost through leaks, many originating from poorly matched fittings or incorrect thread standards.

A correctly identified NPT fitting, installed with proper sealing tape or thread sealant, provides a durable, vibration-resistant connection. This directly impacts energy consumption, machine uptime, and maintenance frequency.

For procurement teams, correct identification also simplifies sourcing. Once the size is confirmed, it’s easier to compare suppliers, standardize inventory, and avoid emergency purchases at premium prices.

Once the thread size is confirmed, material and manufacturing quality become the next priorities. NPT fittings are commonly available in brass, stainless steel, and plated carbon steel, each suited to different environments.

For OEM and distributor customers, consistency matters. Variations in thread taper or pitch tolerance can cause installation issues even when the nominal size is correct. This is why many buyers prefer suppliers that machine threads according to international standards and perform 100% thread inspection.

At FOKCA Automation, NPT fittings are produced with controlled taper accuracy and stable thread profiles, making them compatible with valves, cylinders, and pneumatic components from major brands.

Beyond supplying standard NPT fittings, FOKCA supports OEM and distribution partners with OEM/ODM customization, including special lengths, mixed thread ends, and material upgrades. This is especially useful when replacing imported components or adapting designs for local markets.

FOKCA’s pneumatic fittings are widely used alongside air cylinders, solenoid valves, pneumatic actuators, and air preparation units, allowing customers to source compatible components from a single supplier. This reduces lead times and simplifies quality control.

For distributors, consistent thread quality means fewer after-sales issues. For engineers, it means fewer surprises during installation.

If you have any requirements or questions,please feel free to Contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap