Jan 06, 2026

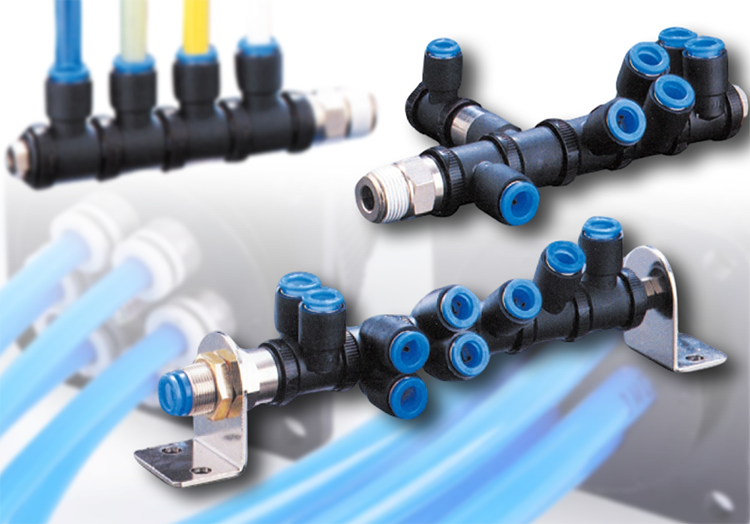

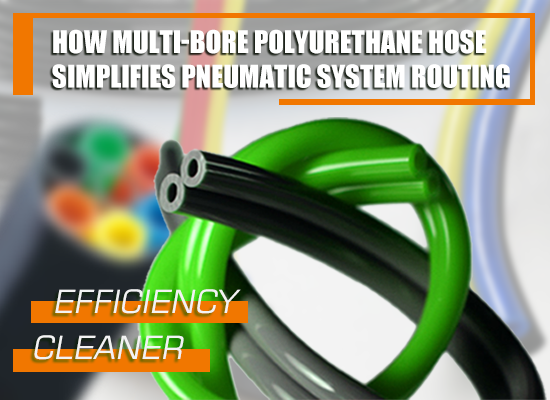

In compact pneumatic systems, multi-bore PU tube tubing is often chosen to simplify routing, reduce installation time, and keep machines visually organized. Compared with single lines, one tube carries multiple air channels, which is especially useful in automation panels, pick-and-place units, and modular equipment. However, when these tubes are connected to PU tube connectors or push-in fittings, small mistakes can lead to leaks, unstable pressure, or premature tube damage. Understanding the connection details makes a real difference in long-term reliability.

Unlike standard polyurethane hose pipe, multi-bore PU tubing contains several independent air channels inside a single outer jacket. Each bore behaves like a small PU tube with its own pressure path, while the outer layer keeps everything aligned and protected.

This structure saves space, but it also means that cut quality and alignment are more critical. If the tube end is not cut cleanly, individual bores may deform, causing uneven sealing once inserted into the fitting. For engineers and installers, this is often the first hidden source of leakage.

Think of it like inserting several thin tubes at the same time—each one must seat correctly.

Not all push-in fittings designed for single tubes are suitable for multi-bore designs. A proper pneumatic quick coupling must match both the outer diameter and the internal bore layout of the tube. Using an oversized fitting may feel “easy to insert,” but it compromises holding force.

For applications that reference SMC polyurethane tubing dimensions, compatibility is especially important. Some multi-bore tubes follow standard OD sizes, while others are custom. Always confirm whether the fitting manufacturer specifies support for multi-bore or flat-tube structures.

Key selection points include:

1.Matching outer diameter tolerance

2.Sufficient gripping length inside the fitting

3.Seal design that accommodates multiple internal channels

These factors are essential for distributors recommending alternatives or replacements.

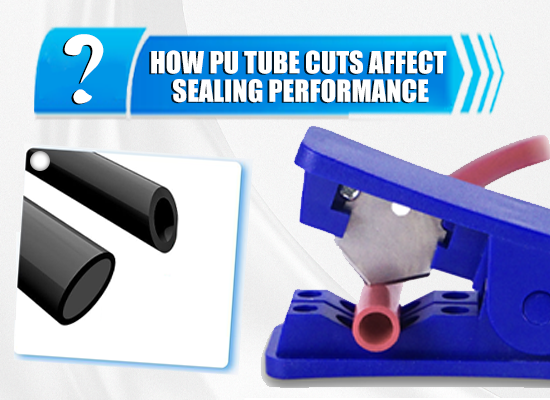

Before inserting any polyurethane tube , the cut must be perfectly square and clean. Angled cuts reduce contact area between the tube and the internal seal, while crushed ends distort the inner bores.

Using a sharp tube cutter rather than scissors helps preserve the tube geometry. After cutting, visually check that each internal bore remains open and evenly shaped. This step takes seconds but prevents troubleshooting hours later.

For multi-bore tubes, avoid twisting the tube during insertion. Twisting can cause uneven loading on the inner bores, especially in tight panel installations.

Push-in fittings rely on correct insertion depth to function properly. With polyurethane hose pipe, installers often rely on “feel,” but multi-bore tubes require more attention. If the tube is not fully seated, one or more internal channels may seal poorly even if others appear fine.

A practical approach is to mark the required insertion depth on the tube before installation. Once inserted, gently pull back to confirm the grip ring has engaged. This method is commonly used by experienced equipment technicians assembling dense pneumatic layouts.

Micro-leaks often originate from partially seated tubes rather than obvious installation errors.

Multi-bore PU tubing is flexible, but excessive bending near the fitting increases stress on the inner channels. Over time, this can cause oval deformation, reducing sealing effectiveness. Always respect the minimum bending radius, especially within the first 30–50 mm from the fitting.

At higher pressures, uneven stress distribution between bores becomes more noticeable. Selecting a tube rated for the actual working pressure — not just nominal values — is critical for system stability and safety.

FOKCA Automation supplies polyurethane tubes and push-in fittings designed with consistent dimensional control, making installation more predictable for OEM and distribution customers. Tube hardness, OD tolerance, and fitting grip geometry are matched to reduce assembly variability.

For distributors, this consistency means fewer complaints and returns. For engineers, it means faster installation and stable performance across different machines. FOKCA also supports OEM/ODM customization, including special bore counts, colors, and paired fitting solutions, helping customers standardize pneumatic layouts without compromise.

Connecting multi-bore PU tube tubing is not difficult, but it rewards careful attention to detail. Correct fitting selection, clean cuts, full insertion, and proper routing together determine whether the system runs quietly for years or develops leaks after weeks.

For projects where space, efficiency, and reliability matter, pairing quality push-to-connect fittings with stable polyurethane tubing — from a supplier that understands both — turns a simple connection into a dependable solution.

If you have any requirements or questions,please feel free to Contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap