Jan 05, 2026

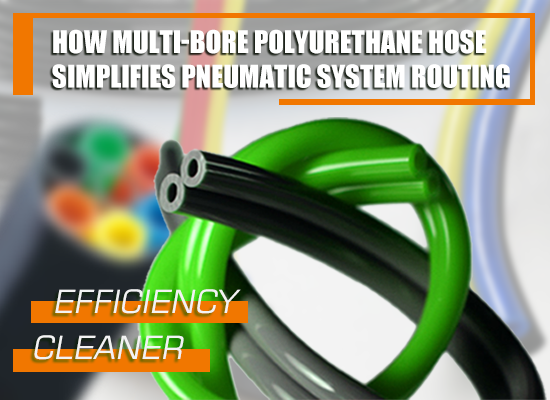

As pneumatic systems become more compact and function-dense, traditional single-line tubing often introduces unexpected complexity. Multiple air lines routed in parallel increase installation time, make maintenance difficult, and raise the risk of misconnection. This is where PUM Multi-Bore Polyurethane Hose provides a clear structural advantage. By combining several pneumatic channels into one unified tube, it simplifies pneumatic system routing without changing fittings or connection methods.

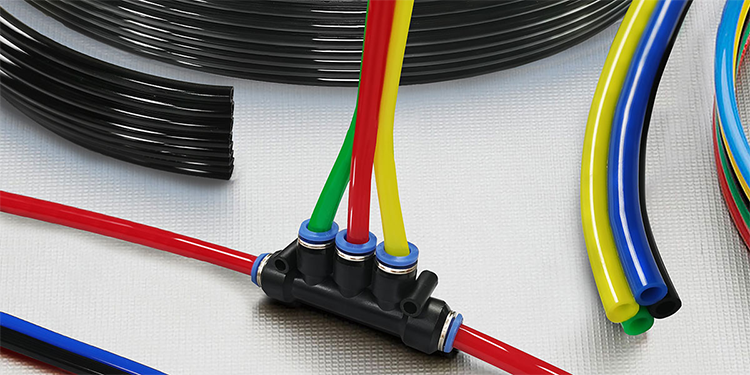

A multi-bore PU tube integrates two or more independent air passages inside a single polyurethane outer jacket. Each internal bore functions as a separate pneumatic line, while the outer tube keeps all lines aligned and protected.

Compared with managing multiple individual hoses, this structure reduces clutter and improves routing consistency. For equipment engineers, it also makes pneumatic layouts easier to design, document, and replicate across machines.

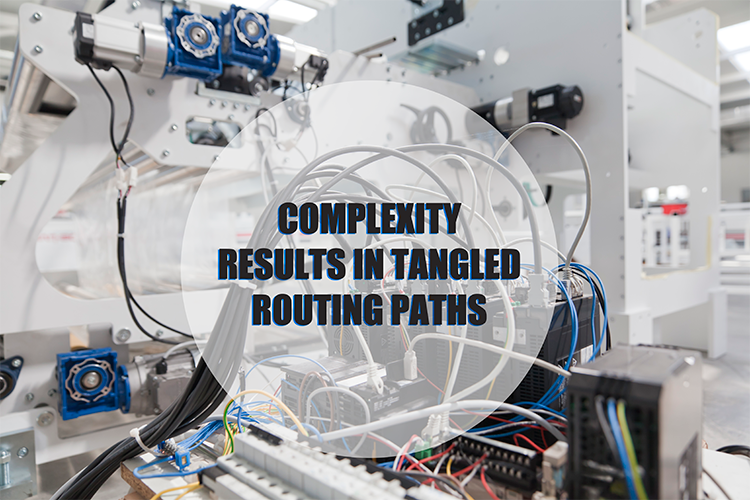

In compact pneumatic systems, multiple air signals frequently need to reach the same actuator group—such as double-acting cylinders, grippers, or valve manifolds. Using separate hoses for each signal often results in tangled routing paths, uneven bend radii, and inconsistent hose lengths.

Over time, these conditions increase installation errors and slow down troubleshooting. Misrouted air lines remain one of the most common causes of commissioning delays in automated equipment. Multi-bore tubing addresses this issue by structurally grouping related air lines from the start.

One of the key benefits of multi-bore polyurethane tubing is improved installation efficiency. Instead of routing and securing several individual hoses, installers handle a single tube assembly with fixed internal channel positions.

Cutting, labeling, and routing become more consistent, especially in serial production. Bending behavior is also more predictable, since all internal air lines share the same bending radius. For OEMs, this reduces variability between machines and shortens assembly time.

With multi-bore tubing, each air channel maintains a defined position within the tube cross-section. This makes air lines easier to identify during installation and maintenance, particularly in control cabinets or moving assemblies.

For distributors and end users, fewer loose hoses mean fewer chances of incorrect reconnection. A clean pneumatic layout is not just visually appealing—it directly reduces downtime and service costs.

Despite its internal complexity, Twin (Multi-row) Hose retains the core advantages of standard PU hose: flexibility, abrasion resistance, and stable pressure performance. Each bore is dimensionally controlled to ensure compatibility with push-in fittings and consistent airflow.

Well-designed multi-bore tubing also minimizes internal twisting between channels, maintaining stable performance in dynamic applications such as pick-and-place systems, packaging machines, and robotic arms.

Multi-bore pneumatic hose is commonly used in applications where space efficiency and organized routing are critical:

1.Valve islands and pneumatic control panels

2.Multi-axis actuators and grippers

3.End-of-arm tooling

4.Packaging and assembly machinery

5.Modular automation equipment

In European and North American markets, structured pneumatic routing is often preferred for both functional clarity and professional equipment appearance.

FOKCA Automation supplies PUM Multi-Bore Polyurethane Hose manufactured with controlled bore spacing and tight dimensional tolerances. This ensures consistent sealing performance when used with standard pneumatic fittings.

For OEM and distributor customers, FOKCA offers customization options including bore count, color-coded channels, hardness selection, and cut-to-length packaging. These options help simplify assembly, reduce installation errors, and improve logistics efficiency.

As pneumatic systems continue to evolve toward higher integration, tubing layout becomes a critical design factor. Multi-bore PU tubing simplifies routing, reduces clutter, and improves system clarity—without increasing component complexity.

For engineers, it enables cleaner designs. For distributors, fewer support issues. For end users, more stable operation. In many cases, optimizing a pneumatic system starts not with adding components, but with simplifying how air is routed.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Dec 26, 2025 Blog

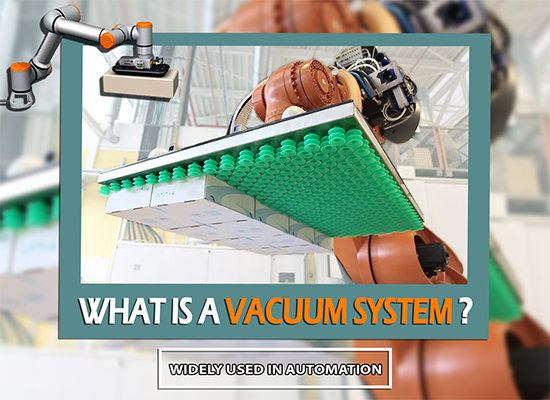

What Is Vacuum and What Is a Vacuum System

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for WaterLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap