Dec 16, 2025

Pioneering reliable solutions for automotive, industrial, and electronics applications, PA66 plastic tubing is a high-performance material that combines strength, rigidity, and durability. As the second most widely used nylon, PA66, together with PA6, accounts for approximately 95% of total nylon consumption, with the remaining 5% made up of specialty nylons. Its superior mechanical properties make it an essential choice for demanding environments, providing a balance between strength, wear resistance, and thermal stability.

PA66 is widely recognized for its high strength, high rigidity, excellent wear resistance, and heat tolerance. Compared with PA6, it delivers slightly higher mechanical performance but is slightly less flexible and more expensive. These characteristics make PA66 ideal for components that must withstand mechanical stress, high temperatures, and continuous operation.

Property | PA6 | PA66 | Notes |

Tensile Strength | 70–80 MPa | 85–90 MPa | PA66 is stronger |

Flexural Modulus | 2.8 GPa | 3.1 GPa | Higher rigidity |

Melting Point | 220 °C | 260 °C | Better heat resistance |

Flexibility | High | Moderate | PA66 slightly less flexible |

Cost | Lower | Higher | Tradeoff for durability |

For distributors, engineers, and procurement managers, understanding these properties ensures the right material selection for long-lasting, high-performance tubing.

PA66 also plays a significant role in industrial machinery, including gears, pulleys, pump housings, and pneumatic systems. Its high rigidity and strength allow it to bear mechanical loads without deformation, while its wear resistance extends service life in moving parts.

For example, air tubing made from PA66 in pneumatic systems can handle repeated pressurization without compromising shape or functionality. This reliability reduces downtime and ensures smooth operation for equipment used in manufacturing lines.

Optional Data: Lifespan comparison between PA6 and PA66 under continuous mechanical stress (Source: Industry Machinery Report, 2023).

The automotive industry relies heavily on PA66 for engine compartment components, brake system parts, and fluid handling tubing. Under the hood, high temperatures, vibration, and exposure to oils and chemicals demand a material that retains mechanical integrity. PA66 tubing is ideal for these environments because of its thermal stability and wear resistance.

Example: A brake fluid line made from PA66 tubing maintains dimensional stability under repeated pressure cycles, reducing maintenance needs and enhancing vehicle safety.

In the electrical and electronics industry, PA66 tubing is employed in connectors, switches, cable insulation, and electronic housings. Its dimensional stability, heat resistance, and mechanical strength make it suitable for protecting wires and components in high-temperature and vibration-prone environments.

FOKCA custom PA66 tubing provides precise protection for delicate wiring assemblies, ensuring compliance with industry safety standards while enhancing operational longevity.

Choosing the right PA66 tubing requires consideration of diameter, wall thickness, temperature range, and chemical compatibility.

For distributors and engineers, selecting tubing that matches application requirements ensures reliable performance and prevents leaks or mechanical failure.

Parameter | Consideration |

Inner Diameter | Match to flow requirements |

Wall Thickness | Ensure mechanical strength |

Temperature Rating | Suitable for operating environment |

Chemical Resistance | Compatible with fluids handled |

Flexibility | Must bend without cracking or kinking |

Correct selection of PA66 plastic tubing prevents costly downtime and increases confidence for OEMs and end-users alike.

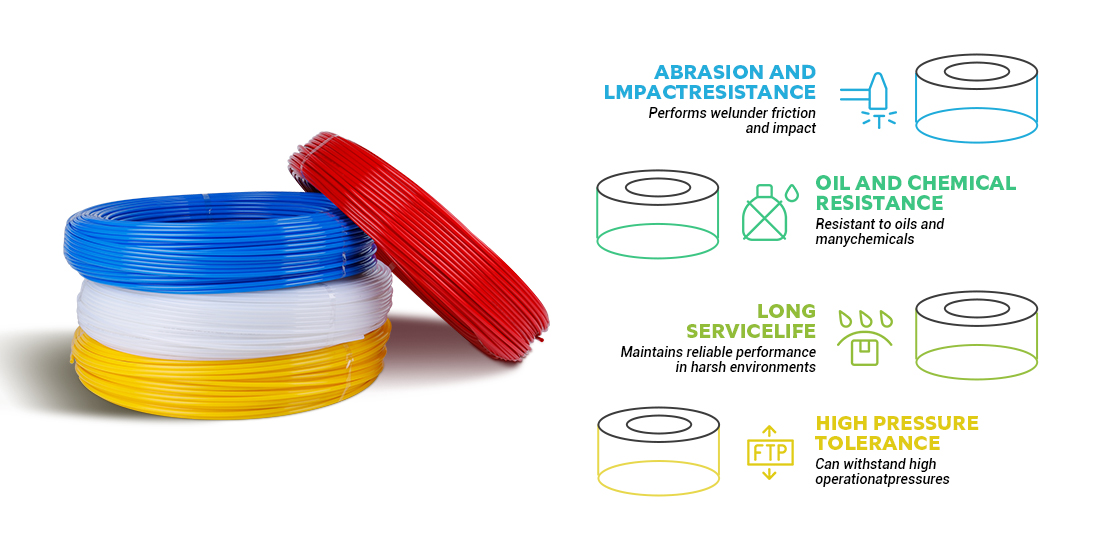

As a global supplier of pneumatic and hydraulic components, FOKCA Automation Co., Ltd. offers a full range of PA66 tubing and custom solutions tailored to industrial requirements. Key advantages include:

◆OEM/ODM flexibility for standard and custom tubing sizes

◆Wide range of products: nylon tubing, fittings, pneumatic components, and accessories

◆Proven durability and quality control, ensuring tubing withstands heat, wear, and chemical exposure

◆Support for automotive, industrial, and electronics sectors, providing high-performance solutions for demanding applications

By choosing FOKCA, distributors, engineers, and procurement managers can ensure long-lasting, reliable nylon tubing that reduces maintenance, minimizes downtime, and maximizes efficiency.

Selecting the right tubing and partnering with a trusted supplier like FOKCA ensures that every component performs as intended, delivering durability, safety, and operational efficiency.

For more detail you can contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap