Dec 17, 2025

In many pneumatic systems, the air hose quick connect is one of the smallest components, yet it often becomes the point where leaks, pressure loss, or maintenance headaches begin. Engineers usually focus on cylinders, valves, or actuators, while quick connections are treated as interchangeable accessories. In practice, the wrong hose quick connection can quietly limit system efficiency, shorten component life, or create safety risks during operation and maintenance.

For distributors, equipment engineers, procurement teams, and end users, selecting the right connector is less about brand names and more about matching the connector to the actual working conditions. Pressure, flow, media, materials, sealing, and compatibility all matter—and they matter together.

Before comparing catalogs or connector shapes, the first step is always the operating environment.

An air hose quick connect must survive the same conditions as the rest of the pneumatic system. This includes working pressure, required flow rate, and working medium. Ignoring these basics is the most common cause of premature failure.

High-pressure applications demand connectors with sufficient safety margins, not just nominal ratings.

Flow rate is equally critical: undersized hose connections create pressure drops that are often misdiagnosed as valve or cylinder problems. When compressed air is replaced or supplemented by other media—such as inert gases, water, or light hydraulic oil—the internal structure and seal material become even more important.

In automated assembly lines, engineers often discover unstable actuator speeds traced back to restrictive hose connections rather than faulty regulators. Choosing based on system requirements first avoids this trap and simplifies later troubleshooting.

Material choice directly affects durability, compatibility, and long-term cost. For hose quick connect fittings, the most common options are carbon steel, brass, nickel-plated brass, and stainless steel. Each material has a clear application logic rather than a simple “better or worse” ranking.

Carbon steel connectors offer high mechanical strength and are suitable for stable indoor environments, especially where cost control is critical.

Brass is widely used for general pneumatic applications because of its corrosion resistance and good machinability.

Nickel-plated brass adds surface hardness and improved wear resistance, making it suitable for frequent connect–disconnect cycles.

Stainless steel stands apart for harsh environments. In food processing, chemical plants, or outdoor equipment exposed to moisture, stainless steel air hose quick connect fittings resist corrosion and contamination far better than other materials. Although the initial cost is higher, lifecycle cost is often lower due to reduced replacement and downtime.

For distributors and procurement teams, offering multiple material options allows better alignment with customer budgets and application risks instead of pushing a single “standard” solution.

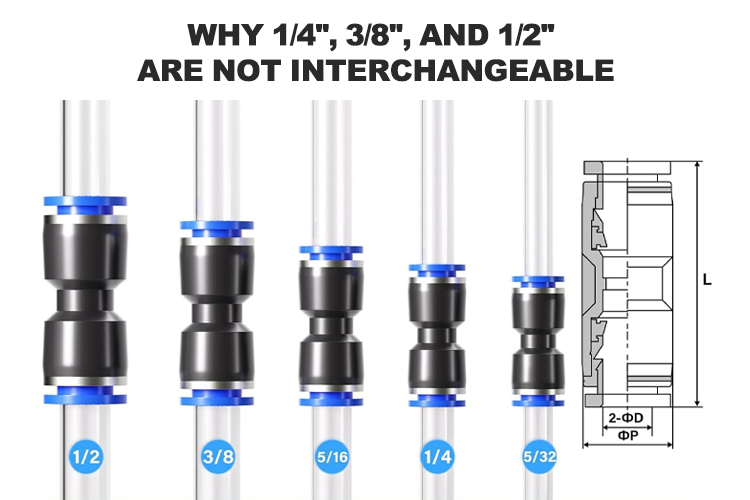

Connector size is often chosen by habit rather than calculation. Common sizes like 1/4'', 3/8'', and 1/2'' are familiar, but they are not interchangeable when flow performance matters. The internal bore of a quick connections determines how much air can pass without excessive pressure loss.

In compact tools or control circuits, a 1/4'' connector may be sufficient. In systems feeding multiple actuators or high-speed cylinders, 3/8'' or 1/2'' connectors often provide more stable pressure and faster response. Undersized connectors can cause inconsistent motion, especially during peak demand.

Many equipment engineers notice improved cycle times simply by upgrading hose connections while keeping the same compressors and valves. Selecting size based on actual airflow demand rather than existing hose threads leads to measurable performance gains.

Sealing is where quick connections either succeed quietly or fail visibly. The seal material must match the working medium and temperature range. NBR (Buna-N) seals are common for compressed air and general industrial use. They offer good elasticity and cost efficiency under moderate temperatures.

For higher temperatures or chemically aggressive environments, Viton (FKM) seals provide excellent chemical resistance and longer service life. In food, beverage, or pharmaceutical applications, EPDM is often preferred due to its compatibility with water and cleaning agents.

Seal selection also affects how smoothly connectors engage and disengage. Poor seal compatibility leads to sticking, leakage, or sudden seal extrusion under pressure. For buyers replacing existing hose connections, checking seal material compatibility is as important as matching thread size.

The locking mechanism defines how a hose quick connect fittings behaves during daily operation. Ball-lock systems are the most common, offering fast connection and secure holding under pressure. They are suitable for most pneumatic tools and automation lines.

Push-to-connect designs emphasize speed and convenience, especially in maintenance-intensive environments. However, they require careful material and tolerance control to avoid accidental disconnection. Threaded safety locks add an extra layer of protection in high-vibration or mobile equipment, where accidental release could be hazardous.

From a sales and engineering perspective, the choice of locking style should reflect how often hoses are connected and disconnected, who performs the operation, and how critical unplanned disconnection would be. There is no universal best choice—only a best match for the application.

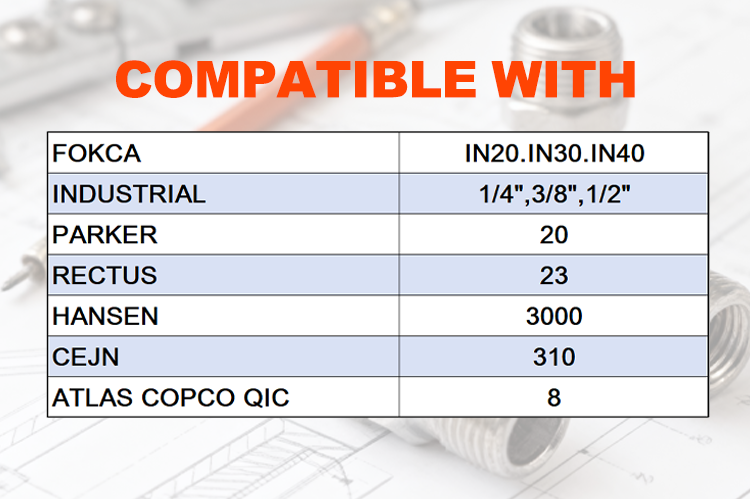

When replacing an existing air hose quick connect, compatibility becomes the central concern. Quick connectors come in many profiles, and different regions often follow different standards. Two connectors may look similar but fail to mate properly or seal reliably.

This is especially relevant for distributors and procurement managers sourcing replacements across regions. Rather than relying on appearance alone, buyers should check whether the supplier provides clear interchangeability references or cross-compatibility charts. Reputable manufacturers typically specify which standards their connectors are compatible with and which they are not.

In mixed-brand systems, a lack of interchangeability documentation often leads to trial-and-error purchasing, wasted inventory, and downtime. Clear compatibility guidance significantly reduces these risks.

A well-selected air hose quick connect rarely draws attention, which is exactly the point. It maintains pressure stability, reduces leakage, shortens maintenance time, and improves overall system reliability. In contrast, a poorly chosen connector quietly increases energy consumption and service costs.

Across automation lines, workshops, and industrial plants, the difference between “any connector” and the right connector is felt over years, not days. By treating hose connections as functional components rather than accessories, companies gain measurable efficiency and operational confidence.

When selection is driven by real operating conditions and supported by suppliers who understand both technical and market requirements, quick connectors become what they should be: simple, reliable, and invisible in daily operation.

For more information on Quick couplings polyolefin tubings, please do not hesitate to Contact us.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap