Dec 04, 2025

When air systems fail, the problem is rarely dramatic — it starts with silent pressure loss, inconsistent actuator speed, or unexplained compressor overload.

In many factories, these issues can be traced back to one overlooked component: the fitting.

This is whereSMC fittingshave earned their reputation in global automation. Produced by SMC Corporation, SMC push to connect fittings are not merely connectors;

they are engineered control points that protect the performance of the entire pneumatic system.

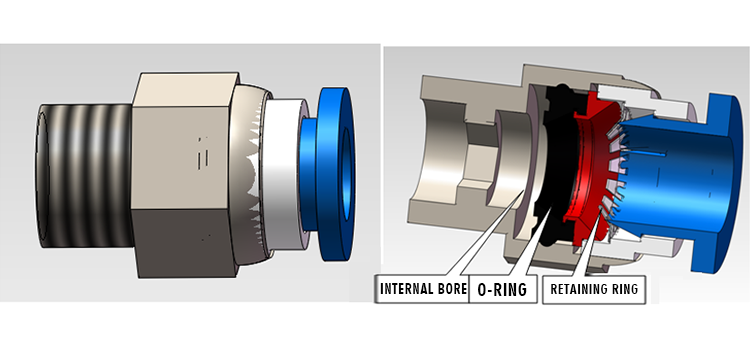

SMC pneumatic fittings are precision-engineered connectors designed to link pneumatic tubing to valves, cylinders,

and air preparation units quickly and securely without tools. The tubing is inserted directly into the fitting body,

where stainless gripping claws lock it in place while elastomer seals maintain airtight integrity.

Unlike ordinary fittings, these connectors are designed as functional system components rather than accessories.

The internal geometry is optimized to control airflow disturbance, minimize turbulence, and maintain consistent pressure delivery — an advantage that becomes visible in high-speed or multi-axis automation environments.

If cylinders are the muscles, fittings are the veins. And in automation, vein quality determines system health.

From the outside, most fittings look similar. The difference emerges after months of operation.

| Feature | Ordinary Pneumatic Connectors | SMC Air Fittings |

|---|---|---|

| Manufacturing Precision | Rely on broad tooling tolerances with inconsistent dimensions | CNC-machined or precision-molded with micrometer-level accuracy |

| Component Consistency | Grip rings, bores, and seal grooves vary between batches | Uniform grip rings, bores, and O-ring channels |

| Effect on Tubing | Higher risk of deformation over time | Reduced tube deformation and long-term stability |

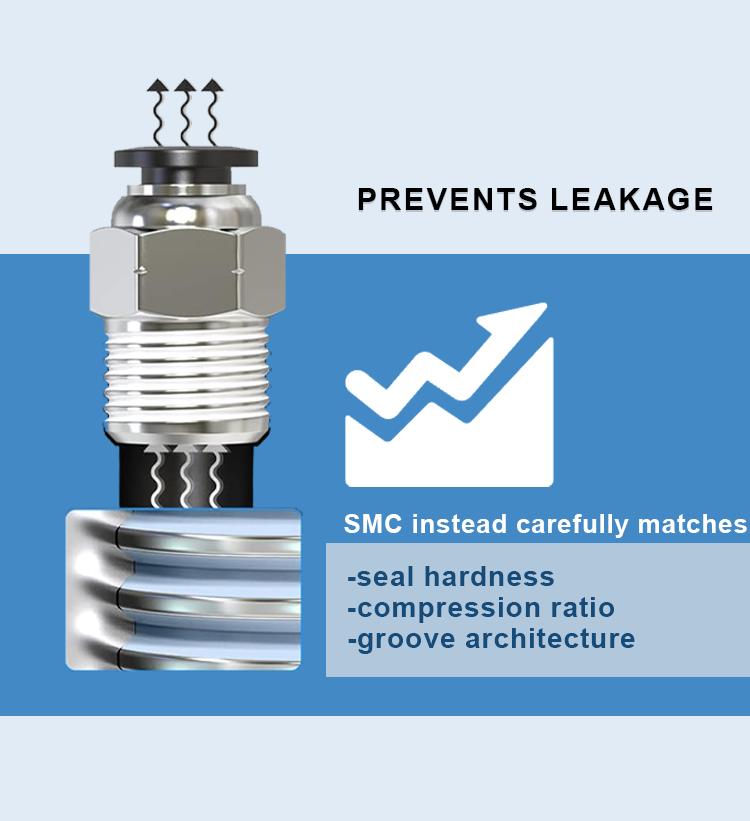

| Sealing System Design | Single flat elastomer seal | Optimized seal hardness, compression ratio, and groove geometry |

| Vibration Resistance | Seals may fail under vibration or temperature changes | Stable sealing even under vibration and temperature fluctuation |

| Grip Mechanism | Uneven gripping pressure | Even force distribution around the tube circumference |

| Blow-out Risk | Higher chance under pressure surges | Lower risk of oval deformation and accidental tube release |

| Service Life | Limited connection cycles and pressure stability | Several times longer lifespan in cycles and pressure retention |

| Quality Validation | Minimal testing | Validated by industry testing and manufacturer lifecycle assessments |

Factories breathe oil mist, vibration, and humidity.

Pneumatic tube fittings from SMC are tested for:

· Thermal expansion

· Pressure surges

· Mechanical vibration

· Tube relaxation

· Chemical exposure

The result is a component that continues sealing even after years of use — not weeks.

Long-term gain:

· Fewer shutdowns

· Lower failure incidents

· Improved asset utilization

Compressed air is expensive. Leaking systems quietly drain profit.

One leaking fitting may waste thousands of dollars each year in energy.

SMC pneumatic fittings reduce this loss with:

· Multi-point sealing

· Controlled tube engagement depth

· Anti-creep elastomers

· Precision bore alignment

Reduced leakage equals reduced compressor load — and direct electricity savings.

In filling lines, carton erectors, and robotic arms, tiny fluctuations in air pressure create visible defects.

SMC pneumatic fittings help eliminate this by forming a consistent internal diameter through the airflow channel.

This matters because pressure disturbances caused by poor fitting geometry propagate through the entire system, especially in complex networks with long hose runs.

What engineers gain:

· Reduced pressure drop

· Faster actuator response

· Stable repeatability in automation cycles

In short: stable airflow creates stable production.

Unlike many brands that focus only on standard connectors, SMC fittings cover industrial use cases across multiple sectors:

Application Area | Typical SMC Fitting Series |

Food & Beverage | Stainless push fittings |

Robotics | Compact swivel connectors |

Packaging | High-speed release types |

Semiconductor | Clean-room materials |

Automotive | Reinforced high-pressure types |

Medical Devices | Miniature polymer connectors |

This product depth allows OEM builders to source all fittings from one ecosystem — simplifying technical documentation and spare parts planning.

While SMC delivers world-class engineering, availability and customization are challenges in some markets.

This is where FOKCA becomes a strategic partner.

FOKCA supplies:

· SMC-equivalent fittings with compatible tolerances

· OEM/ODM customization for projects requiring non-standard threads or tubing

· Large-volume inventory for distributors

· Fast prototyping for machine builders

· Cost-controlled alternatives without sacrificing quality

For buyers, this creates a safety net — ensuring production continues even when supply chains stall.

Making the Right Choice: Engineer & Buyer Checklist

Is vibration present? → Choose reinforced metal fittings

Is hygiene required? → Stainless steel models

Is space tight? → Compact elbow/swivel types

High cycle count? → Premium push fittings only

Urgent delivery? → FOKCA equivalent options available

If you would like to learn more about pneumatic push-in fittings, pneumatic tubing, or other air-line components, please feel free to contact us at any time.

FOKCA is committed to providing you with the most professional support and service.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-RetardantLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap