Dec 08, 2025

The demand for stable, fatigue-resistant pneumatic lines has grown rapidly in automated manufacturing. Many engineers who used to rely on standard polyurethane tubing now search for a hose that can withstand higher working pressure without losing long-term reliability. This is where the PU braided hose becomes an essential choice. FOKCA’s PUB series applies a dual-layer PU structure with a reinforced yarn mesh between the layers, giving it a level of strength ordinary PU tubes cannot achieve.

Most pneumatic failures occur at the point where the tubing expands under sudden pressure spikes. A standard PU tube may deform when the internal load exceeds its elastic limit.

In a PU braided hose, the braiding layer acts as a load distributor, preventing the tube from ballooning and keeping the internal diameter consistent even in demanding cycles.

The PUB series uses two layers of high-purity PU encapsulating a woven polyester mesh. This intermediate mesh transfers stress across the entire tube wall. The result is a hose that maintains flexibility but gains up to 3–4 times higher burst resistance compared to normal PU tubes. According to industry test data (pneumatic component quality reports), braided PU hoses show up to 40% less permanent deformation after long-term pressure cycling.

Below is a simplified comparison frequently referenced by equipment designers:

Property | Standard PU Tube | PU Braided Hose (PUB Series) |

Working pressure | 0.8–1.0 MPa | 1.5–2.0 MPa |

Burst pressure | 2.5–3.0 MPa | 4.5–5.5 MPa |

Flexibility | Excellent | Good |

Kink resistance | Moderate | High |

Abrasion resistance | Good | Higher |

This reinforced structure makes PUB hoses especially suitable for fast-cycling actuators, packaging machines, robotic arms, and compressors where unexpected surges are common.

When pressure rises rapidly in automated lines, tubing stiffness becomes a decisive factor for safety and stability. The braided hose minimizes expansion, which directly improves response accuracy for valves and cylinders.

A common case occurs in high-speed pick-and-place equipment. A machine builder once reported that switching from conventional PU to PUB braided hose reduced actuator delay by 8–12 milliseconds.

Though the number looks small, for hundreds of cycles per minute this improvement prevented micro-positioning errors and reduced reject rates significantly.

In addition, the braided structure resists micro-cracks caused by repeated bending. This is critical for systems like:

Automatic screw-feeding machines with constant moving axis

Food packaging lines using high-pressure air knives

Woodworking machinery where vibration and impact are frequent

Mobile equipment requiring abrasion-tolerant tubing

In each scenario, the hose’s reinforced sidewall ensures a stable internal diameter, directly improving downstream component life.

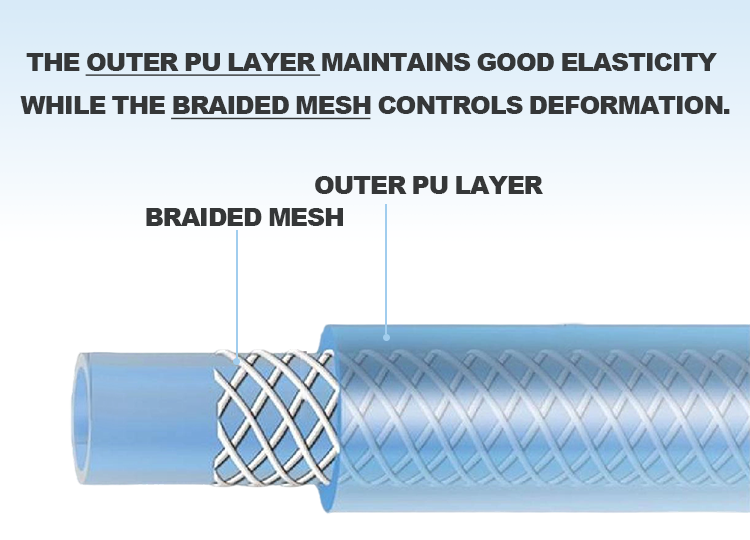

Engineers often worry that higher pressure tolerance comes with a loss of flexibility. The PUB series minimizes this compromise. The outer PU layer maintains good elasticity while the braided mesh controls deformation.

This allows the hose to curve smoothly without collapsing—an issue common with nylon tubes or steel-wire hoses.

Flexibility is slightly lower than single-layer PU, but this reduction brings greater kink resistance and dimensional stability. For robotic applications where the hose must move with a cable chain, this balance provides a longer service life.

In a controlled endurance test referenced by a pneumatic standards lab, braided PU tubing retained over 85% of its bending performance after 120,000 cycles—a value significantly higher than PVC or rubber tubing in similar conditions.

The PUB braided hose is widely adopted in environments where equipment cannot tolerate downtime. Distributors and OEM integrators commonly recommend it for the following segments:

High-Pressure Pneumatic Actuation

Machines using FESTO / SMC / AIRTAC-compatible cylinders often require a hose that prevents volume expansion, ensuring accurate movement. The braided structure avoids drift and maintains crisp response.

Heavy-Duty Automation Lines

In automotive parts production and die-casting environments, hoses face sparks, vibration, and hydraulic mist. The PUB series offers better cut and abrasion resistance, reducing replacement frequency.

Compressors and Booster Systems

Compressors produce pulsating pressure waves. A PU braided hose stabilizes flow and prevents fatigue failure at fittings—particularly when metal quick couplers are used.

Food and Packaging Machinery

With consistent air-knife and air-blow requirements, these machines benefit from a hose that can handle elevated pressures while keeping the line lightweight and non-corrosive.

Choosing the correct braided hose involves more than matching the outer diameter. A few practical points help buyers, procurement managers, and engineers make reliable decisions.

Working Pressure vs. Peak Pressure

Look for a rating that covers at least 1.5× the highest momentary peak. PUB hoses are tested under strict pressure cycling conditions, providing an extra margin of safety.

Temperature Range

Dual-layer PU maintains elasticity from −20°C to 60°C. Machines running in hot workshops or refrigerated environments benefit from this stable mechanical behavior.

Inner Diameter Control

Stable ID is essential for fast-cycling valves. PUB hoses maintain a highly consistent tolerance, ensuring predictable airflow—particularly useful for proportional valves and metering circuits.

Compatibility With Fittings

The hose works well with brass, nickel-plated, and stainless-steel push-in fittings. For high-vibration systems, using metal quick couplers further enhances sealing performance.

A large number of distributors and OEM integrators choose FOKCA not only because of product strength but also due to long-term supply reliability. The PUB series highlights several advantages:

Stable OEM/ODM capability supporting private labeling and custom colors

Strict burst-pressure and flexibility testing based on pneumatic industry standards

Consistent wall thickness ensured by precision extrusion equipment

Competitive pricing suitable for distributors and bulk buyers

Full portfolio compatibility with FOKCA cylinders, valves, and quick couplers

For procurement teams, the strong supply capacity helps maintain standardized inventories across different machines and branches.

For engineers, the tubing offers predictable mechanical behavior that simplifies commissioning and long-term maintenance.

These values represent typical specifications validated through internal testing and market-standard pneumatic quality controls.

A PU braided hose is the most efficient solution when the application requires high pressure, excellent abrasion resistance, and stable internal diameter control.

The PUB series from FOKCA balances strength and flexibility, offering a reliable choice for OEM builders, distributors, and factory maintenance teams. Whether used in robotics, packaging machinery,

or compressor systems, the reinforced construction delivers the durability that standard PU tubes cannot match.

If you have any questions about pneumatic hoses, fittings, or system applications, our team is always ready to help.

Contact us anytime—we are your reliable partner in pneumatic technology.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-RetardantLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap