Dec 02, 2025

In pneumatic systems, leakage rarely comes from one dramatic failure. Instead,

it grows quietly through connection points — and no connector is more misunderstood than the pneumatic push-in fittings.

Fast to install and widely used in automation, packaging, and robotics, these fittings save assembly time but demand correct selection and handling.

When misapplied, they become the most common source of air loss in modern factories.

Many distributors assume leaks indicate “low-quality fittings.” In reality, over 70% of field failures are caused by incorrect usage rather than manufacturing defects.

Engineers and purchasing managers who understand how pneumatic push in fittings actually fail can reduce downtime, warranty returns, and energy waste dramatically.

Below are the causes behind leaking pneumatic push-in fittings, explained with engineering logic and purchasing perspective.

Every pneumatic connector has a defined working pressure — yet this is often ignored during system design.

Standard plastic body pneumatic push in air fittings are usually rated at 1.0 MPa (145 PSI), while brass or stainless-steel models can handle more. When pressure exceeds specification:

◆ Internal seals deform slowly

◆ O-rings lose elasticity

◆ Micro-cracks form around the thread base

The failure rarely happens instantly. Instead, leakage emerges after weeks of overload.

According to implementation guidance from ISO in pneumatic system safety standards,

operating components above rated pressure can reduce sealing lifespan by over 40%.

◆ Engineering reminder: Always select fittings based on actual peak pressure, not just nominal operating pressure.

Push-in connectors rely on two critical parts: the metal gripping collet and the elastic O-ring.

Frequent tubing changes wear both. Aggressive pulling without releasing the collar damages:

◆ Locking teeth

◆ Seal compression zone

◆ Alignment surfaces

Once worn, fittings may still “hold the tube” but lose airtight integrity under vibration.

Systems that require frequent layout changes — test benches, modular lines, R&D rigs — face accelerated failure without reinforced fittings.

Field advice: When disassembly is frequent, use fittings with stainless-steel locking claws and industrial-grade O-rings.

An incomplete insertion is one of the cheapest mistakes — and also the costliest.

Inside a Pneumatic Quick Connector, the O-ring sits deeper than visible. If the tube only enters past the collet but not into the seal, air escapes internally.

Correct connection requires:

◆ Square cut tubing (90°)

◆ No cracks or burrs

◆ Insertion until solid stop

◆ Light pull test

Small visible gaps often become leakage paths when pressure rises.

Simple rule: No resistance, no seal.

This is the most dangerous “almost correct” installation error.

For example, a 6 mm tube pushed into a 1/4" (6.35 mm) fitting enters easily — but locks poorly. Initial performance looks normal. Under pressure, it slips.

This mistake causes intermittent air loss and sudden tube ejection.

Distributor warning: Do not let convenience override compatibility.

Material stiffness matters more than appearance.

Old nylon or low-grade polyurethane tubing becomes rigid with age or heat exposure. Hard tubing cannot maintain radial pressure against O-rings, especially under:

◆ Vibration

◆ Temperature cycles

◆ High-flow bursts

Industry data from Parker Hannifin confirms that exceeding recommended tubing hardness doubles seal failure probability.

Use tubing rated for pressure and elasticity retention.

Some of the worst leaks come from outside the system:

◆ Chemical vapors attack rubber compounds

◆ Fine dust prevents full sealing

◆ Low temperatures shrink O-rings

◆ Aggressive cleaners dissolve polymers

Food and pharmaceutical factories experience the fastest degradation due to frequent sanitation processes.

Engineering mindset: Environment choice is as important as size selection.

In real-world automation systems, air leaks don’t announce themselves with alarms. Leakage is not just a maintenance issue.

It affects cycle time, control accuracy, and long-term reliability. More importantly, it often signals incorrect selection rather than defective components.

Choosing the right pneumatic push in air fittings protects not just pipelines — but entire production lines.

More related examples can be found on YouTube:Why Is Your Push-to-Connect Fitting Leaking Air ?

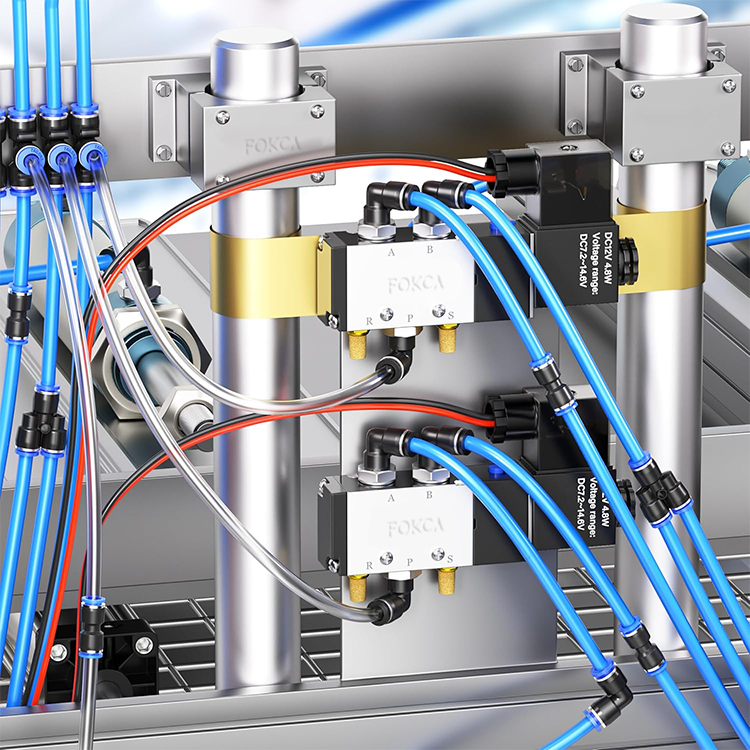

At FOKCA, you can always find the most suitable pneumatic fittings for your application.

We not only supply a full range of pneumatic push-in fittings in various specifications, but also deliver complete pneumatic connection solutions tailored to your system.

Our designs focus on pressure rating, insertion cycle life, media compatibility, and precision locking mechanisms to ensure stable and long-term performance.

If you have any questions about pneumatic fittings, feel free to contact us at any time. Our team is ready to provide you with professional support and the best possible service.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-Retardant

Sep 24, 2025 Blog

Can polyurethane tubing be used for fuel lines?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap