Dec 01, 2025

When selecting a polyurethane pipe for compressed air systems, “95A” is not just a number on a datasheet—it defines how the tubing behaves in real working conditions.

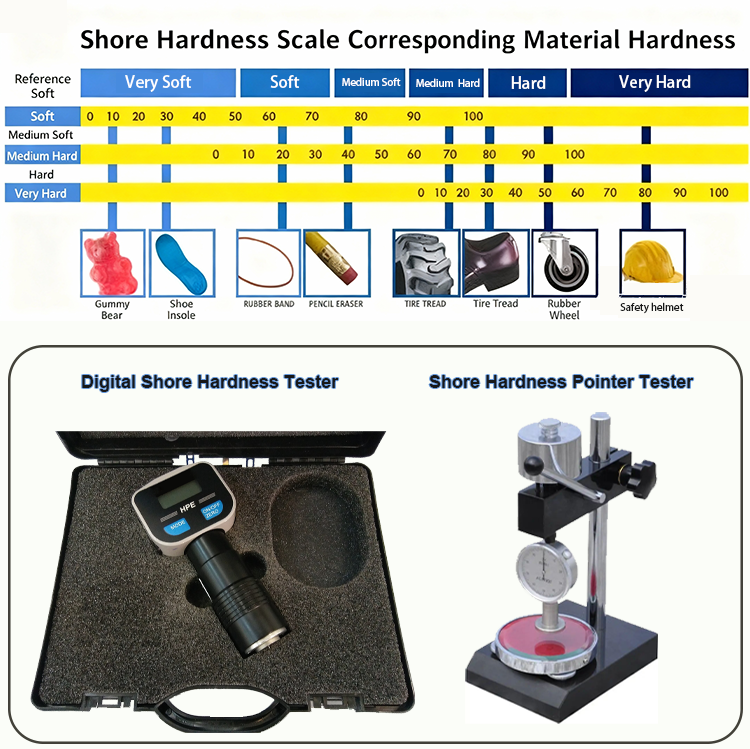

The “A” refers to Shore A hardness, a standardized scale used to measure the softness and elasticity of materials such as polyurethane.

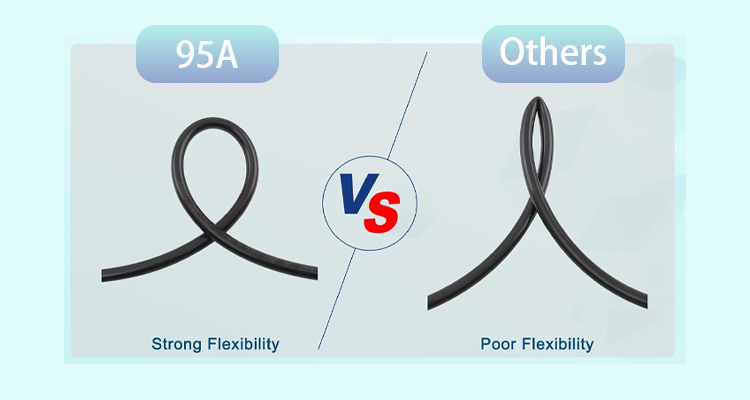

A hardness of 95A means the tubing offers an ideal balance between flexibility and structural strength, sitting between ultra-soft hoses and rigid plastic tubing.

In applications where pneumatic tubing must tolerate mechanical stress while maintaining ease of routing, this specification becomes a deciding factor.

Hardness plays a direct role in how air tubing performs under pressure. Softer tubes may kink or expand under load, while overly rigid tubing is prone to cracking in dynamic environments.

A 95A polyurethane tubing structure resists internal deformation, allowing stable airflow even under repeated pressure cycles.

This characteristic makes 95A pipes suitable for automated assembly lines, packaging machinery, and robotic arms where movement and airflow must stay consistent.

One of the most common frustrations with plastic tubing is difficult routing in compact equipment. Engineers prefer tubing that bends smoothly without losing its shape.

A 95A pu tube offers controlled flexibility—easy to insert, route, and connect, yet rigid enough to hold position under vibration.

Compared with ultra-soft lines, it also resists collapse when vacuum or negative pressure is applied. This directly reduces downtime during installation and servicing.

A polyurethane pipe is often exposed to oil mist, lubricants, cleaning agents, and metal fragments. Hardness influences surface durability,

and 95A offers excellent abrasion resistance. It also shows strong tolerance toward hydraulic oils, diluted acids, and alkalis.

According to industry material studies from polymer testing laboratories, polyurethane significantly outperforms PA and PVC in durability.

This translates into longer service life and fewer replacements in demanding factory environments.

FOKCA’s standard pneumatic tubing is manufactured to 98A hardness, giving higher pressure resistance and shape retention.

However, in applications requiring frequent bending or manual installation, 95A polyurethane is often preferred.

Choosing between the two depends on working conditions:

| Item | 95A PU Tube | 98A PU Tube |

|---|---|---|

| Tactile feel | Flexible yet tough | Relatively rigid |

| Bending performance | ★★★★☆ | ★★☆☆☆ |

| Kink resistance | Strong | Average |

| Sealing fit | Excellent | Slightly poorer |

| Vibration resistance | Excellent | Average |

| Low-temperature flexibility | Good | Average |

| Pressure resistance | Slightly lower (but still suitable for standard pneumatic systems) | Higher |

| Scratch / wear resistance | Good | Better |

| Shape retention | Slightly weaker | Better |

| Recommended Use | Mobile equipment, compact systems, frequent bending | High pressure lines, long fixed routing, heavy-duty setups |

If you would like to learn more about pneumatic tubing, pneumatic push-in fittings, or other air-line components, please feel free to contact us at any time.

FOKCA is committed to providing you with the most professional support and service.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Nov 27, 2025 Blog

Why PVC Pipe Is Flame-Retardant

Sep 24, 2025 Blog

Can polyurethane tubing be used for fuel lines?

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap