Jan 13, 2026

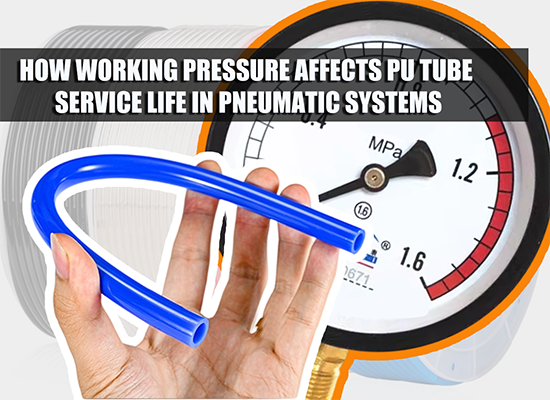

In real-world pneumatic and hydraulic applications, pressure rarely behaves in a smooth, steady manner. Rapid valve switching, actuator cycling, and system start-stop events all generate pulsating pressure. For many pneumatic tube systems, this repetitive pressure fluctuation becomes a silent contributor to premature hose failure. Understanding how PUB Braided Polyurethane Tube performs under such conditions helps engineers, distributors, and buyers make more reliable long-term decisions.

Pulsating pressure is not limited to high-pressure hydraulic circuits. In pneumatic tubes, frequent solenoid valve actuation and fast cylinder movement can create sharp pressure spikes that repeatedly load and unload the tube wall. Over time, this cyclic stress accelerates material fatigue even when the average working pressure appears well within rated limits.

In many pneumatic tube systems, these pressure pulses occur thousands of times per shift. While each individual pulse may seem harmless, their cumulative effect often leads to tube expansion, loss of dimensional stability, and eventual leakage at fittings. This explains why some pneumatic tubes fail unexpectedly despite operating below their nominal pressure rating.

Standard single-layer polyurethane or PVC pneumatic tubes rely entirely on the tube wall to absorb pressure changes. Under pulsating conditions, the tube repeatedly expands and contracts in the radial direction. This constant deformation gradually weakens the polymer structure, especially at stress concentration points such as bends and fittings.

Common failure modes include micro-cracks, wall thinning, and permanent deformation that prevents proper sealing. Increasing wall thickness may delay failure, but it also reduces flexibility and often transfers stress to other parts of the pneumatic tube system. In dynamic applications, this trade-off rarely delivers a satisfactory long-term result.

These limitations are the primary reason why reinforced solutions are increasingly specified for demanding applications.

The key advantage of braided polyurethane tubing lies in its ability to redistribute stress. By introducing a tube braid between the inner and outer layers, internal pressure pulses are converted into tensile forces along the braided fibers rather than being absorbed solely by the polymer wall.

When pressure rises suddenly, the pu braid tightens and limits radial expansion. When pressure drops, the structure returns to its original state with minimal residual deformation. This controlled response significantly reduces cyclic strain on the inner PU layer, directly improving fatigue resistance.

Compared to ordinary pneumatic tubes, a braided polyurethane hose maintains dimensional stability over far more pressure cycles, even when subjected to rapid and irregular pulsation patterns.

A typical PUB Braided Polyurethane Tube uses a three-layer composite structure, each layer addressing a specific engineering challenge.

| Layer | Function | Engineering Value |

|---|---|---|

| Inner PU layer | Flow channel | Smooth surface, abrasion resistance |

| Braided reinforcement | Structural support | Pressure stability, fatigue resistance |

| Outer protective layer | Environmental protection | Abrasion and oil resistance |

This layered design allows pressure management, flexibility, and durability to coexist without compromise. In pulsating environments, the braided layer becomes the primary load-bearing element, protecting the inner tube from repetitive stress damage.

In automated production lines, robotic equipment, and packaging machinery, pneumatic systems often operate continuously with rapid pressure fluctuations. Under these conditions, pu braided hose solutions consistently outperform standard pneumatic tubes in service life and reliability.

Field observations show that systems using PUB Braided Polyurethane Tube experience fewer fitting-related leaks and maintain consistent outer diameter over time. This stability is especially valuable for distributors and maintenance teams, as it reduces unplanned downtime and replacement frequency.

For procurement managers, the slightly higher initial cost is often offset by lower maintenance expenses and improved system uptime.

As a global pneumatic component supplier, FOKCA Automation designs braided polyurethane tubing with practical system compatibility in mind. Our tubes are developed to match common pneumatic fittings, valves, and cylinders used across automation equipment, ensuring stable integration within complete pneumatic tube systems.

Through OEM and ODM services, FOKCA supports customers who require customized dimensions, pressure ratings, or material combinations tailored to pulsating-pressure environments. This system-oriented approach helps distributors and end users deliver consistent performance across different applications and markets.

When pulsating pressure is present, tube selection should prioritize fatigue resistance over nominal pressure rating alone. The structural advantages of PUB Braided Polyurethane Tube make it a reliable choice for systems where pressure stability, durability, and long-term performance matter.

By understanding how braided reinforcement alters stress behavior inside pneumatic tubes, engineers and buyers can avoid common failure patterns and build systems that perform reliably under real operating conditions.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Jan 12, 2026 Blog

Air Brake Tube for Heavy-Duty Truck Braking Systems

Jan 09, 2026 Blog

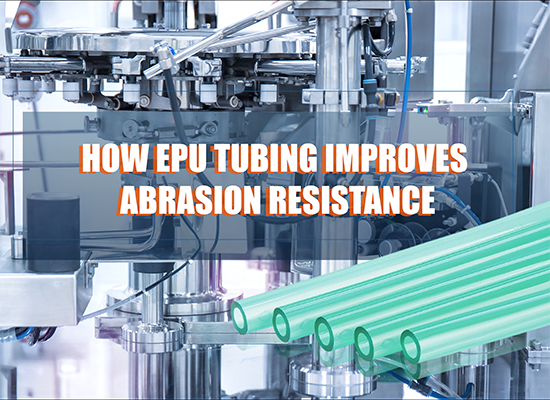

How EPU Tubing Improves Abrasion Resistance

Jan 08, 2026 Blog

What Is a Pneumatic Silencer and Why Do You Need One

Jan 07, 2026 Blog

How to Choose the Right Hex Head Plug

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Dec 08, 2025 Blog

PU Braided Hose for High-Pressure Pneumatic Systems

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose MenderLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap