Jan 09, 2026

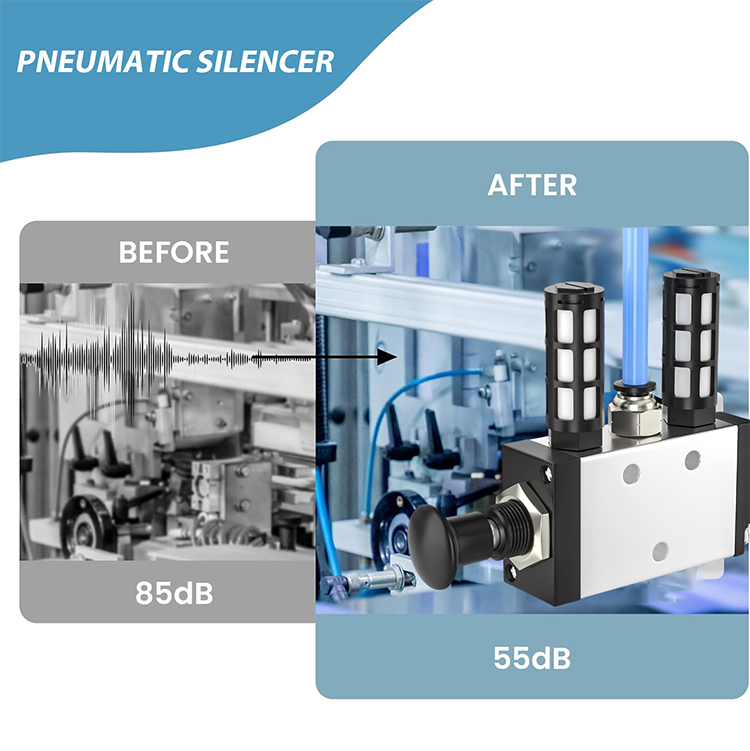

In compressed air systems, exhaust noise is often treated as a secondary issue—until it becomes a real problem on the shop floor. High exhaust noise affects operator comfort, safety compliance, and even the perceived quality of a machine. A pneumatic silencer, sometimes called a pneumatic muffler , is a small component, but its material choice directly impacts performance, durability, and cost.

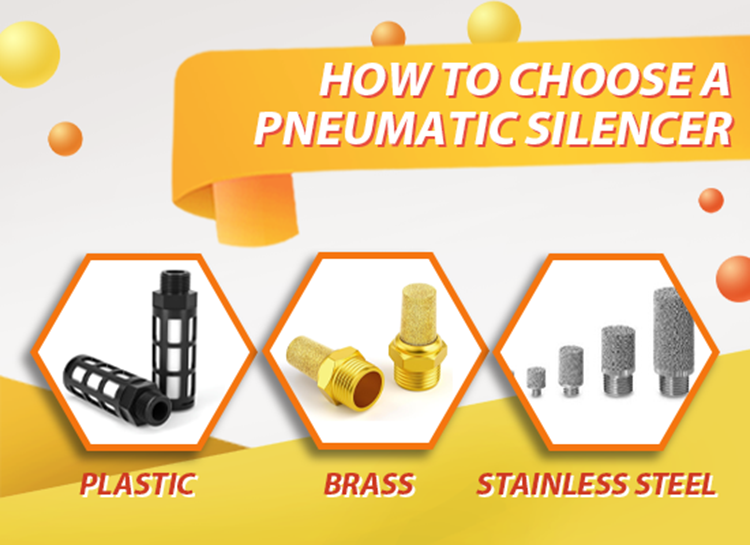

Brass pneumatic silencers, stainless steel silencers, and plastic pneumatic mufflers all serve the same basic function, yet they behave very differently in real applications. Choosing the wrong material can lead to premature clogging, corrosion, airflow restriction, or unnecessary cost. Understanding these differences is essential for engineers, buyers, and distributors alike.

At a technical level, a pneumatic silencer reduces noise by diffusing exhaust air through a porous structure. The material of that structure determines airflow resistance, corrosion behavior, temperature tolerance, and service life.

In practical terms, this means the same muffler design can perform very differently depending on whether it is made from brass, stainless steel, or plastic. For distributors and OEM customers, material choice also affects inventory strategy, target industries, and long-term customer satisfaction.

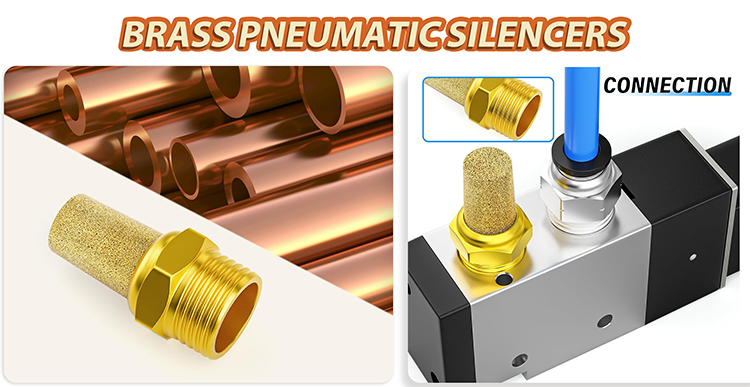

A brass pneumatic silencer is one of the most widely used solutions in industrial automation. Brass offers a balanced combination of strength, machinability, and corrosion resistance, making it suitable for most standard factory environments.

From an engineering perspective, brass provides stable pore structure and consistent airflow. It handles moderate exhaust temperatures well and resists wear better than plastic alternatives. For general-purpose machines—such as packaging equipment, assembly lines, and standard pneumatic cylinders—brass silencers deliver reliable noise reduction without overengineering.

Typical advantages of brass pneumatic silencers include:

1.Good corrosion resistance in dry or mildly humid air systems

2.Stable airflow characteristics, minimizing back pressure

3.Cost-effective for large-scale installations

4.Broad compatibility with common valve ports (M5 to 1")

That said, brass is not immune to aggressive chemicals or constant washdown environments. In food processing plants using alkaline cleaners, or in coastal areas with high salinity, brass may discolor or degrade over time.

Brass silencers are often the first recommendation for distributors serving general industrial customers.

A stainless steel silencer is typically selected when environmental conditions exceed the limits of brass. Stainless steel—especially grades like 304 or 316—offers superior resistance to corrosion, chemicals, and high temperatures.

In real-world applications, stainless steel pneumatic mufflers are common in food and beverage production, pharmaceutical equipment, chemical processing, and outdoor machinery. These environments demand materials that maintain performance even under constant cleaning, moisture exposure, or aggressive media.

From a performance standpoint, stainless steel silencers maintain structural integrity at higher exhaust temperatures and withstand repeated pressure cycles without deformation.

Key reasons to choose a stainless steel silencer:

1.Excellent corrosion and chemical resistance

2.High temperature tolerance for continuous-duty systems

3.Long service life in harsh or regulated environments

4.Suitable for washdown and hygienic applications

The trade-off is cost. Stainless steel silencers are typically more expensive than brass or plastic options. However, in environments where failure or contamination is unacceptable, the higher upfront cost is often justified by reduced downtime and maintenance.

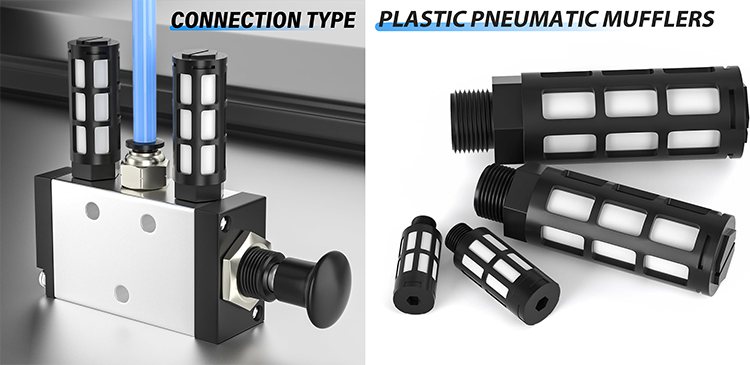

A plastic pneumatic muffler is often associated with lightweight equipment, compact systems, or cost-sensitive applications. Typically manufactured from engineering plastics such as nylon or POM, plastic silencers are easy to install and resistant to certain chemicals.

Plastic mufflers perform well in low-pressure, low-temperature environments and are commonly found in laboratory equipment, medical devices, and small automation units. Their non-metallic nature also eliminates concerns about surface corrosion.

However, plastic has clear limitations. Under continuous high airflow or elevated temperatures, plastic mufflers may deform or lose structural integrity. Their porous elements can also clog more easily in oily air systems.

Plastic pneumatic mufflers are best suited for:

1.Clean, dry compressed air systems

2.Compact or portable equipment

3.Applications where weight and cost are critical factors

4.Light-duty exhaust noise reduction

For OEMs producing high-volume, price-sensitive machines, plastic silencers can be an effective solution when used within their limits.

Choosing between these materials is easier when viewed side by side. The table below summarizes practical differences relevant to engineering and procurement decisions.

Material | Durability | Corrosion Resistance | Temperature Resistance | Cost Level | Typical Applications |

Brass pneumatic silencer | Medium–High | Good | Medium | Medium | General automation, packaging, machinery |

Stainless steel silencer | Very High | Excellent | High | High | Food, pharma, chemical, outdoor equipment |

Plastic pneumatic muffler | Low–Medium | Selective | Low | Low | Light-duty, clean environments |

This comparison helps distributors and system designers align product selection with actual operating conditions rather than assumptions.

Material selection should never be isolated from airflow requirements. A poorly chosen pneumatic muffler—regardless of material—can introduce excessive back pressure, reducing cylinder speed or affecting valve response.

Brass and stainless steel silencers typically offer more stable airflow characteristics due to their rigid structure. Plastic mufflers, while effective for noise reduction, may restrict flow sooner under high exhaust volumes.

For high-speed cylinders or large valve exhaust ports, it is often advisable to oversize the silencer slightly to maintain system efficiency. Noise reduction should not come at the expense of machine performance.

Another often overlooked factor is maintenance. In oily compressed air systems, silencers can clog over time. Brass and stainless steel silencers can usually be cleaned or backflushed, extending service life. Plastic mufflers are often treated as disposable components.

From a total cost of ownership perspective, a stainless steel silencer may outlast multiple plastic units in demanding environments, even if the initial purchase price is higher.

Procurement teams increasingly evaluate silencers based on lifecycle cost, not just unit price.

As a global pneumatic components supplier, FOKCA provides brass pneumatic silencers, stainless steel silencers, and plastic pneumatic mufflers covering common thread standards and airflow ranges.

For distributors and OEM partners, FOKCA offers:

◆OEM/ODM customization, including thread size, filtration grade, and branding

◆Stable supply for high-volume projects

◆Material selection guidance based on application and market positioning

◆Compatibility with FOKCA valves, cylinders, and fittings for integrated solutions

This flexibility allows partners to offer the right silencer material without overcomplicating their product portfolio.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Jan 08, 2026 Blog

What Is a Pneumatic Silencer and Why Do You Need One

Jan 07, 2026 Blog

How to Choose the Right Hex Head Plug

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap