In pneumatic and fluid transfer systems, flow instability is often attributed to pressure fluctuations, fittings, or compressor performance. However, in practice, one frequently overlooked factor is the hardness selection of the inner PU layer in a PUB Braided Polyurethane Tube. For systems that demand consistent airflow or liquid delivery, inner-layer material behavior under pressure plays a decisive role.

Why Inner Layer Hardness Matters in Polyurethane Tubes

A polyurethane tubes pipe PU is not a rigid conduit. Polyurethane is an elastic material, and its mechanical response to internal pressure directly affects internal diameter stability. When the inner PU layer is too soft, the tube tends to expand under pressure, causing temporary increases in inner diameter and localized turbulence. When the material is excessively hard, flexibility decreases, increasing installation stress and long-term fatigue risk.

For PU polyurethane braided tubes, the inner layer is the primary interface with the medium. Its hardness determines how the tube reacts dynamically to pressure changes, pulsation, and repeated cycling.

Deformation Behavior Under Working Pressure

In real pneumatic applications—such as automated assembly lines or valve-controlled air circuits—pressure is rarely static. Rapid opening and closing of solenoid valves introduce short-term pressure spikes. Under these conditions:

◆Low-hardness PU (below typical design range)

The inner wall expands more noticeably, leading to micro-volume changes. This can cause inconsistent flow rates, delayed actuator response, and unstable sensor readings.

◆High-hardness PU (above optimal range)

Deformation is minimal, but the tube becomes less forgiving during bending or vibration, increasing the risk of stress concentration at fittings.

A PUB Braided Polyurethane Tube is designed specifically to manage this balance. The braid limits radial expansion, but the inner PU layer must still absorb part of the pressure load.

Flow Stability Is a Structural Issue, Not Just a Pressure Issue

Flow stability depends on maintaining a consistent internal cross-section. Even minor diameter fluctuations can affect airflow velocity and pressure drop, especially in long tube runs or precision pneumatic systems.

In testing environments and field applications, tubes with improperly selected inner PU hardness often exhibit:

◆Unstable actuator speed

◆Inconsistent air consumption data

◆Audible pressure oscillation in high-frequency systems

This is why professional manufacturers do not select PU hardness arbitrarily. The inner layer must work with the braided reinforcement, not against it.

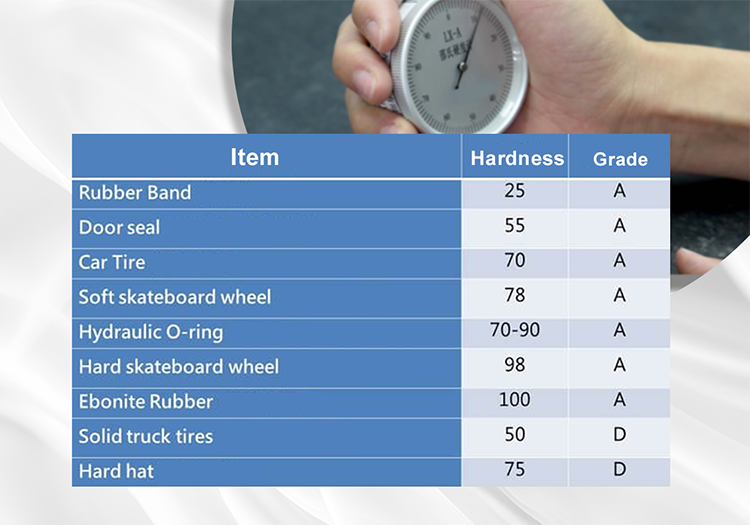

Typical Inner PU Hardness Ranges and Their Effects

The table below illustrates how different inner-layer hardness levels influence performance characteristics in braided polyurethane tubes:

| Inner PU Hardness (Shore A) | Deformation Under Pressure | Flow Stability | Flexibility | Typical Use Case |

|---|---|---|---|---|

| 80–85A | High | Moderate | Excellent | Low-pressure, flexible routing |

| 88–92A (Common Choice) | Controlled | Stable | Balanced | Industrial pneumatic systems |

| 95A+ | Minimal | High | Limited | Straight runs, rigid installations |

Industry data based on pneumatic hose material testing and application feedback.

The 88–92 Shore A range is widely adopted for the inner layer of PUB Braided Polyurethane Tube because it offers a practical balance between elastic control and mechanical durability.

Why Braided PU Tubes Still Need the Right Inner Hardness

Some users assume that the polyester or fiber braid alone ensures pressure stability. In reality, the braid mainly limits maximum radial expansion. The inner PU layer still governs:

◆Initial elastic response

◆nergy absorption during pressure spikes

◆Long-term dimensional recovery after repeated cycles

If the inner layer is poorly matched, the braid cannot compensate for internal flow disturbance or fatigue-related deformation.

Durability, Wear Resistance, and Long-Term Flow Consistency

Besides flow stability, inner PU hardness also affects abrasion resistance. Media containing oil mist, particles, or moisture can gradually wear the inner surface. Medium-hardness PU materials provide better resistance to inner-wall erosion without becoming brittle.

This is particularly relevant in automated factories where tubes operate continuously for thousands of cycles. A stable inner diameter over time translates directly into predictable system behavior and reduced maintenance.

FOKCA’s Approach to PUB Braided Polyurethane Tube Design

At FOKCA, PUB Braided Polyurethane Tube inner layers are formulated within a controlled hardness window based on pressure rating, tube diameter, and application type. Rather than maximizing hardness, the focus is on functional stability—maintaining flow consistency while preserving installation flexibility and service life.

This approach allows FOKCA to support distributors, OEM customers, and end users who require repeatable performance across different equipment and environments, not just compliance with nominal pressure specifications.

Choosing the Right Tube for Stable Performance

When selecting a polyurethane tubes pipe PU for braided applications, inner layer hardness should be evaluated alongside pressure rating and reinforcement structure. For most industrial pneumatic systems, a moderately hard PU inner layer combined with braided reinforcement provides the most reliable flow behavior.

This is one of the key reasons why PUB Braided Polyurethane Tube remains a preferred solution in automation, machinery manufacturing, and factory air systems where stability matters as much as strength.

(FK9026)