Jan 08, 2026

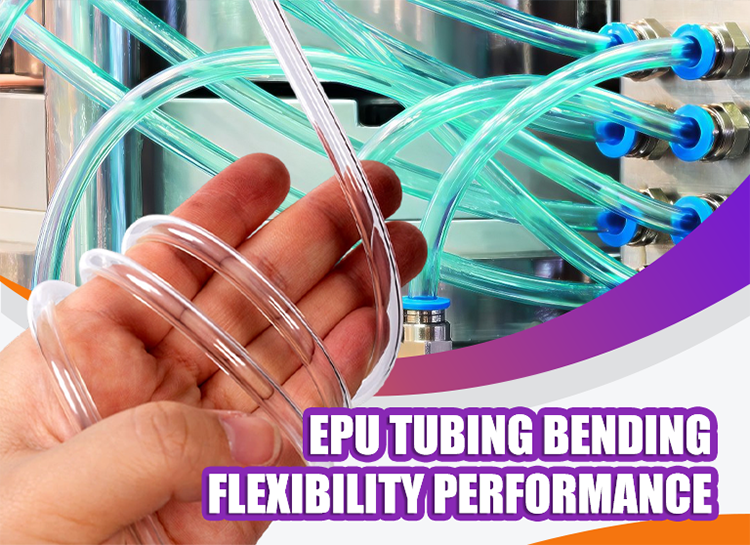

In pneumatic systems, tubing flexibility is often treated as a secondary concern—until repeated bending starts to cause kinks, cracks, or premature failure. For applications involving continuous movement, tight routing, or compact machine layouts, tubing flexibility directly affects system reliability. This is where EPU (Ether-Based Polyurethane) tubing shows clear advantages compared to standard polyurethane tubing.

Understanding the bending behavior of Ether-Based Polyurethane Tubing helps engineers, buyers, and distributors make more informed material choices, especially in demanding automation environments.

Pneumatic tubing rarely stays static. In automated equipment, tubes bend repeatedly due to cylinder motion, robotic arms, or sliding assemblies. Each bend introduces stress into the tubing wall, especially at fixed connection points.

When tubing lacks sufficient flexibility, common problems appear:

1.Kinking under tight bend radii

2.Surface cracking after repeated cycles

3.Reduced airflow due to internal deformation

For end users and maintenance teams, these issues translate into downtime and replacement costs. For OEMs, they can affect machine reputation and warranty claims.

The key difference lies in the polymer structure. EPU Ether-Based Polyurethane Tubing uses ether-based soft segments instead of ester-based ones. This molecular structure provides greater elasticity and resilience under dynamic stress.

Compared to conventional polyurethane tubing, EPU tubing offers:

1.Higher flexibility at the same hardness

2.Better resistance to repeated bending

3.Improved performance in low-temperature environments

These properties make EPU tubing especially suitable for moving pneumatic lines where bending is unavoidable rather than occasional.

One practical way to evaluate tubing flexibility is by looking at minimum bending radius and fatigue life. A smaller bending radius means the tubing can be routed more tightly without kinking or collapsing.

In repeated motion tests, EPU polyurethane tubing typically maintains its shape and airflow characteristics over more cycles than standard PU tubing. This is because the ether-based structure distributes stress more evenly across the tube wall instead of concentrating it at one point.

For equipment engineers, this means more freedom in layout design without sacrificing durability.

Flexibility is not only about room-temperature behavior. In colder environments, many tubing materials become stiff and brittle, increasing the risk of cracking.

Ether-Based PU Tube retains elasticity at lower temperatures, which helps maintain bending performance in cold workshops, refrigerated areas, or seasonal outdoor installations. This stability under temperature variation is a key reason why EPU tubing is often selected for dynamic pneumatic systems rather than static air lines.

Because of its bending resistance and flexibility, EPU tubing is commonly used in:

◆Robotic automation and pick-and-place systems

◆Moving pneumatic connections on cylinders

◆Compact machinery with tight tube routing

◆Equipment requiring frequent repositioning

For distributors, EPU tubing is often positioned as a premium alternative to standard polyurethane tubing, offering longer service life in motion-heavy applications.

At FOKCA, EPU tubing is produced with controlled material formulation and extrusion parameters to ensure consistent wall thickness and elasticity. This consistency is critical for predictable bending behavior across different batches.

Key advantages include:

◆Stable flexibility across standard metric and inch sizes

◆Smooth inner surface to maintain airflow under bending

◆Compatibility with common pneumatic fittings

For OEM and ODM customers, FOKCA also supports customization of tubing dimensions, colors, and packaging to match specific equipment requirements.

While EPU Ether-Based Polyurethane Tubing may have a higher initial cost than standard PU tubing, its resistance to bending fatigue often results in longer service intervals and fewer unexpected failures.

For engineers, it enables more compact and dynamic designs. For buyers and factory managers, it reduces maintenance frequency. For distributors, it provides a clear value-based upgrade option rather than a simple price comparison.

In pneumatic systems where motion is constant, flexibility is not a detail—it is a defining performance factor.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Jan 08, 2026 Blog

What Is a Pneumatic Silencer and Why Do You Need One

Jan 07, 2026 Blog

How to Choose the Right Hex Head Plug

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap