Jan 12, 2026

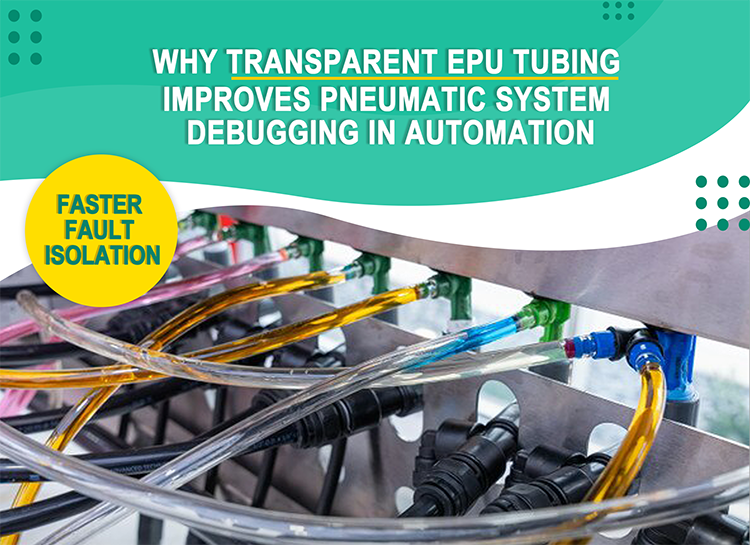

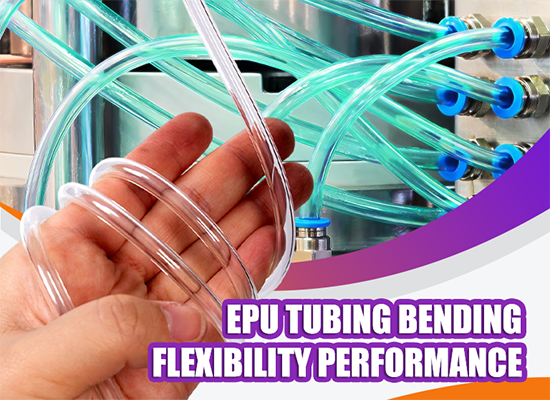

In pneumatic and automation systems, many performance issues do not originate from valves or actuators, but from what happens inside the tube. Air contamination, moisture, oil carryover, or unstable flow are often invisible until a failure occurs. This is where transparent EPU Ether-Based Polyurethane tubing provides a practical advantage over conventional opaque PU pneumatic tubes, especially during system setup, debugging, and early-stage operation.

For equipment engineers, distributors, and end users, tube transparency is not an aesthetic feature. It directly affects diagnostic efficiency, commissioning time, and long-term maintenance cost.

EPU (ether-based polyurethane) tubing differs from common ester-based PU mainly in material structure and performance stability. While both belong to the family of polyurethane pneumatic tubing, EPU offers superior resistance to hydrolysis, better flexibility at low temperatures, and more stable mechanical properties over long service cycles.

When EPU tubing is produced in a transparent or semi-transparent form, it combines material durability with visual accessibility. Compared with standard opaque PU hoses, transparent EPU tubing allows engineers to observe internal conditions in real time without dismantling the system.

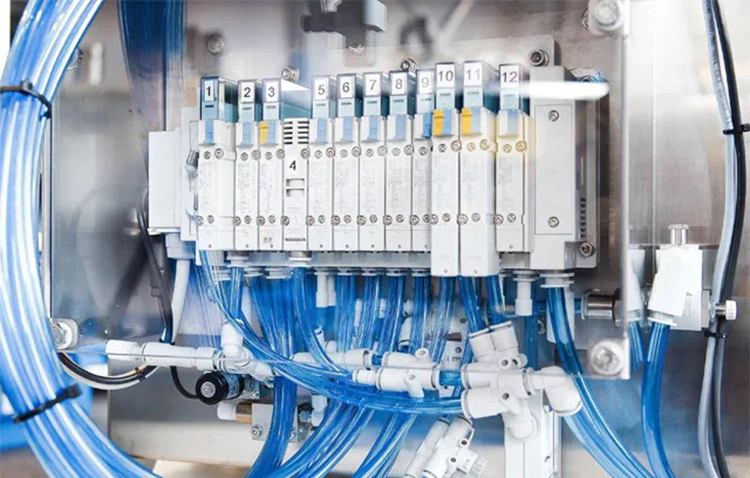

During commissioning and debugging, engineers often need to confirm whether air flow is stable, whether condensate is present, or whether oil mist distribution is uniform. With opaque PU pneumatic tube , these checks rely on indirect judgment, pressure readings, or repeated disassembly.

Transparent EPU Ether-Based Polyurethane tubing turns the tube itself into a diagnostic window. Air bubbles, moisture droplets, oil accumulation, or unexpected contaminants become immediately visible. This reduces trial-and-error adjustments and shortens system debugging time, particularly in complex automation lines.

In automated equipment, even small pneumatic issues can stop an entire production line. When faults occur, maintenance teams need to locate the problem quickly. Transparent EPU tubing simplifies fault isolation by making abnormal flow conditions visually obvious.

For example, a partially blocked tube, intermittent moisture carryover, or backflow caused by valve timing issues can often be identified visually before pressure drops trigger alarms. Compared with standard polyurethane hoses, this visual feedback helps reduce unplanned downtime and maintenance labor.

The advantages of transparent EPU tubing become clearer when compared side by side with ordinary PU pneumatic tubes:

| Performance aspect | Transparent EPU tubing | Standard PU tubing |

|---|---|---|

| Internal visibility | Clear view of air, moisture, oil | Not visible |

| Hydrolysis resistance | Excellent | Moderate |

| Low-temperature flexibility | Stable | Reduced in cold conditions |

| Debugging efficiency | High | Limited |

| Maintenance support | Visual inspection possible | Requires disassembly |

This comparison explains why transparent EPU tubing is increasingly specified for automation equipment that requires frequent commissioning, adjustment, or monitoring.

Transparent EPU tubing is widely used in pick-and-place systems, robotic arms, packaging machines, and test equipment. In these applications, frequent motion, rapid cycling, and precise timing make pneumatic stability critical.

During initial setup or equipment modification, engineers can visually confirm air quality and flow behavior without stopping the system. For distributors and OEM customers, this translates into easier installation support and fewer technical complaints after delivery.

In pneumatic systems, the ability to see what is happening inside the tube reduces uncertainty. Transparent EPU tubing transforms routine debugging into a faster, more controlled process. Compared with ordinary PU pneumatic tubes, it offers measurable benefits in commissioning speed, fault diagnosis, and maintenance efficiency.

For automation equipment builders, distributors, and end users, transparent EPU Ether-Based Polyurethane tubing is not just a material upgrade—it is a practical tool for improving system reliability and operational confidence.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Jan 12, 2026 Blog

Air Brake Tube for Heavy-Duty Truck Braking Systems

Jan 09, 2026 Blog

How EPU Tubing Improves Abrasion Resistance

Jan 08, 2026 Blog

What Is a Pneumatic Silencer and Why Do You Need One

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap