Jan 09, 2026

Compared with ester-based PU tubing, EPU tubing uses a polyether-based molecular structure, which provides better resistance to mechanical wear while maintaining flexibility.

From a material standpoint, EPU tubing exhibits:

1.Higher surface toughness, reducing material loss under friction

2.Stable elasticity, allowing the tube to recover shape after repeated bending

3.Reduced micro-cracking on the outer surface

These characteristics are especially important in dynamic applications where tubing movement is continuous rather than occasional.

Abrasion Performance Comparison of Common Pneumatic Tubing

Property | EPU Tubing (Ether-Based PU) | PU Tubing (Ester-Based) | PA Nylon Tubing |

Abrasion resistance | High | Medium | Medium |

Flexibility under motion | High | High | Low |

Surface wear rate | Low | Medium | Medium |

Suitability for drag chains | Well suited | Limited | Poor |

Service life in dynamic use | Long | Moderate | Short |

This balance of abrasion resistance and flexibility makes EPU tubing particularly effective in high-cycle motion environments.

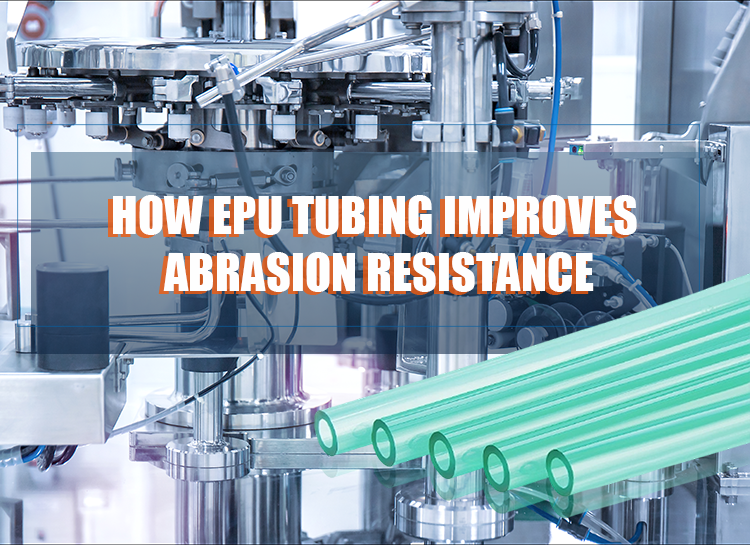

Ether-Based Polyurethane Tubing is widely used in applications where motion frequency and mechanical contact are unavoidable. In these systems, material durability directly affects uptime and maintenance cost.

Typical high-frequency pneumatic applications include:

◆Robotic arms and end-effectors

◆Pick-and-place automation

◆Linear slides and transfer units

◆Cable carriers and energy chains

◆Compact machines with dense pneumatic routing

In these scenarios, polyurethane ether tubing maintains structural integrity longer than conventional materials, even when routing conditions are less than ideal.

From a maintenance perspective, abrasion-related failures are among the most disruptive. Tubing wear often occurs gradually and may go unnoticed until leakage affects system performance.

Using abrasion-resistant EPU polymer ether based polyurethane tubing reduces:

1.Unexpected air leaks

2.Emergency downtime

3.Frequent tube replacement

For procurement teams and plant managers, this translates into lower total cost of ownership, even if the initial tubing cost is slightly higher than standard PU alternatives.

Lifecycle Impact of Abrasion-Resistant EPU Tubing

Factor | Standard PU Tubing | EPU Tubing |

Replacement frequency | Higher | Lower |

Maintenance labor | Repeated interventions | Reduced |

Downtime risk | Moderate to high | Low |

Long-term operating cost | Higher | More predictable |

The economic advantage becomes more evident as machine speed and operating hours increase.

In high-frequency pneumatic applications, tubing selection should prioritize abrasion resistance and motion durability, not just pressure rating or flexibility.

EPU Ether-Based Polyurethane Tubing offers a proven solution where repeated movement, friction, and vibration are unavoidable. By extending service life and stabilizing maintenance cycles, EPU tubing supports both engineering reliability and long-term cost control.

For systems where motion never stops, tubing material choice makes a measurable difference.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Jan 08, 2026 Blog

What Is a Pneumatic Silencer and Why Do You Need One

Jan 07, 2026 Blog

How to Choose the Right Hex Head Plug

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap