Jan 07, 2026

Multi-bore polyurethane tubing is widely used in automation equipment where multiple pneumatic or fluid lines must be routed through a compact space. Compared with standard single-bore polyurethane tubing, Multi-Bore Polyurethane Hose offers clear advantages in installation efficiency and line organization. However, its internal structure also introduces maintenance risks that are often underestimated, especially when technicians apply the same practices used for ordinary PU tubing.

Understanding these differences is critical for avoiding premature failure, unstable pressure delivery, and unnecessary downtime.

Unlike standard Polyurethane Tubing, which contains a single airflow channel, multi-bore PU tubing consists of several small, independent bores molded into one profile. During operation, pressure, temperature, and contamination levels may vary slightly between channels.

A common oversight is treating the hose as a single unit during inspection. In reality, partial blockage or deformation in just one bore can affect signal accuracy or actuator response while the outer tube still appears intact. This is a failure mode rarely seen in single-bore tubing but frequent in PUM Multi-Bore Polyurethane Hose used in control systems.Regular maintenance should include individual bore airflow checks, especially in applications involving sensors or synchronized pneumatic actions.

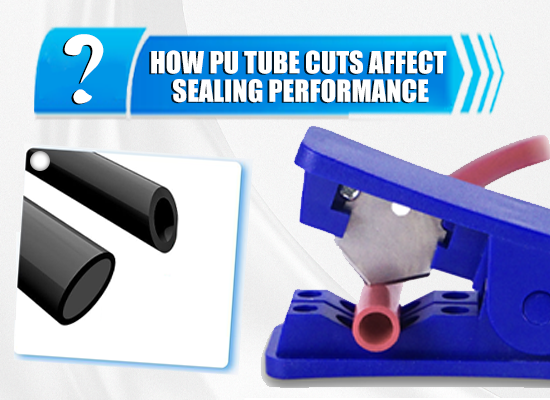

For ordinary PU tubing, minor cutting imperfections often have limited impact. With multi-bore designs, however, uneven or angled cuts can cause internal bore misalignment, leading to partial sealing at fittings.

This issue is often overlooked during installation or replacement. A slightly crushed internal channel may not leak externally but can restrict airflow internally, creating inconsistent system behavior.

Using sharp, dedicated cutting tools and ensuring perfectly perpendicular cuts is significantly more important for multi-bore tubing than for standard polyurethane tubing.

Maintenance teams often flush standard PU tubing with compressed air or cleaning agents without concern for internal geometry. In multi-bore polyurethane hoses, this approach can leave contaminants trapped in individual channels.

Dust, oil mist, or condensed moisture may accumulate unevenly across bores. Over time, this leads to flow imbalance, pressure delay, or valve response issues.

Effective maintenance requires controlled cleaning procedures that ensure all internal channels are cleared, rather than relying on surface-level inspection alone.

All polyurethane tubing has a specified minimum bending radius, but the consequences of exceeding it differ. In single-bore tubing, excessive bending typically results in visible kinking. In multi-bore tubing, internal channel collapse can occur without obvious external deformation.

This makes routing design and periodic inspection especially important. Repeated micro-bending during machine operation can gradually deform specific bores while leaving others unaffected.

Compared to standard PU tubing, multi-bore hoses require stricter routing discipline to maintain long-term reliability.

A frequent mistake is pairing multi-bore polyurethane tubing with fittings originally selected for standard tubing layouts. While external diameters may match, internal sealing performance can vary.

Uneven compression across the tubing profile may seal some bores effectively while leaving others partially restricted. This is rarely an issue with single-bore tubing but is a known risk in multi-channel systems.

Selecting fittings designed or tested for multi-bore polyurethane hose applications reduces long-term maintenance risk and improves system consistency.

FOKCA manufactures Polyurethane Tubing and PUM Multi-Bore Polyurethane Hose with consistent internal geometry and controlled material hardness, ensuring uniform performance across all channels.

Key advantages include:

1.Stable bore alignment for predictable airflow in each channel

2.OEM/ODM customization, including bore count, spacing, color coding, and hardness

3.Process-controlled extrusion, reducing internal deformation risk over time

4.Compatibility with standard pneumatic systems used by distributors and equipment manufacturers

For distributors, engineers, and procurement teams, this translates into fewer field issues, easier installation guidance, and lower lifecycle maintenance costs.

Multi-bore PU tubing is not simply “several standard tubes combined into one.” Its compact design changes how stress, contamination, and wear develop internally. Applying standard PU tubing maintenance logic without adjustment is one of the most common reasons for early failure.

By understanding these differences and selecting properly manufactured multi-bore polyurethane tubing, users can significantly improve system stability and long-term performance.

If you have any requirements or questions,please feel free to Contact us.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 23, 2025 Blog

How to install compression fitting on copper pipeLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap