Jan 09, 2026

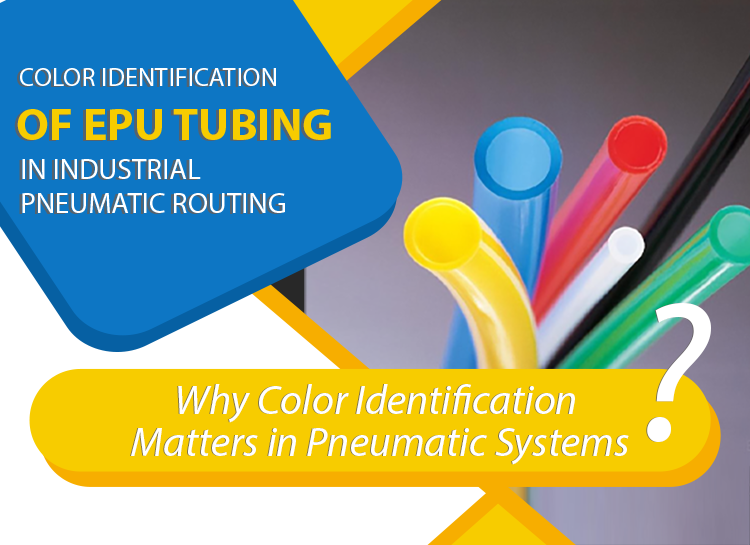

As industrial equipment becomes more compact and pneumatic systems more complex, tubing management is no longer a minor design detail. Clear identification of air lines directly affects installation accuracy, maintenance efficiency, and operational safety.

In this context, color identification using EPU Ether-Based Polyurethane Tubing has become a practical and widely adopted solution in industrial pneumatic routing.

EPU tubing—also known as polyether polyurethane tubing or epu polymer ether based polyurethane tubing—combines material durability with excellent visual clarity, making it especially suitable for color-coded pneumatic systems.

In machines with multiple pneumatic circuits, unmarked or visually similar tubing often leads to confusion during installation and maintenance. Misidentifying a line can result in incorrect connections, extended downtime, or unintended machine behavior.

Color-coded EPU tubing provides instant visual differentiation between circuits, allowing engineers and technicians to understand the system layout at a glance. This is particularly valuable in compact equipment where tubing is densely routed and space for labels is limited.

Impact of Color Identification on Pneumatic System Management

Aspect | Without Color Coding | With Color-Coded EPU Tubing |

Installation accuracy | Higher risk of misconnection | Clear circuit separation |

Maintenance speed | Manual tracing required | Faster fault isolation |

System readability | Poor in compact layouts | Improved visual clarity |

Downtime risk | Higher during repairs | Reduced |

Training requirement | Longer learning curve | Easier for new operators |

From both engineering and operational perspectives, color identification turns tubing into an active system management element.

Not all pneumatic tubing materials perform equally when pigments are added.

EPU polymer ether-based polyurethane tubing maintains stable mechanical properties while offering long-term color consistency.

Compared with ester-based PU tubing, EPU tubing provides better resistance to moisture and hydrolysis. This helps prevent material degradation and color fading in humid environments, washdown areas, or continuous-duty systems.

EPU Tubing vs Other Common Pneumatic Tubing Materials

Property | EPU Tubing (Ether-Based PU) | PU Tubing (Ester-Based) | PA Nylon Tubing |

Color stability | High, long-term clarity | Medium | High |

Hydrolysis resistance | Excellent | Limited | Excellent |

Flexibility | High | High | Low |

Dynamic bending | Well suited | Suitable | Not recommended |

Visual identification | Consistent over time | May degrade | Stable but rigid |

This balance of flexibility, durability, and color performance makes EPU tubing particularly suitable for industrial color identification.

There is no single global standard for pneumatic tubing colors, but many OEMs and system integrators follow internal conventions to ensure consistency and clarity within the same machine or production line.

Typical Color Identification in Pneumatic Routing

Color | Typical Application | Practical Meaning |

Blue | Main compressed air supply | Quick identification of air source |

Black / Clear | General pneumatic circuits | Standard applications |

Red | Safety or emergency-related lines | Visual warning |

Green | Control or feedback circuits | Separation from power air |

Yellow | Auxiliary or temporary lines | Non-permanent connections |

The key principle is not the specific color, but consistent use across the entire system.

Color-coded EPU tubing delivers its greatest value over the equipment’s service life. During maintenance, technicians can quickly locate and isolate specific circuits without disconnecting the wrong line. This reduces troubleshooting time and minimizes the risk of secondary faults.

In safety-sensitive applications, color identification also serves as a visual warning. Lines connected to emergency functions or high-pressure zones can be immediately recognized, reducing accidental disconnection during operation.

From a cost perspective, faster maintenance and fewer errors translate into lower total operating costs, even if the tubing itself is not the lowest-cost option.

As a global pneumatic components supplier, FOKCA offers EPU tubing in multiple standard and custom colors, covering common diameters and hardness ranges for industrial automation.

Color identification in EPU tubing is not about aesthetics. It is a functional design choice that improves system clarity, enhances safety, and simplifies maintenance.

When combined with the mechanical advantages of polyether polyurethane tubing, color coding becomes a small design decision that delivers long-term operational value—for engineers, buyers, distributors, and end users alike.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Jan 08, 2026 Blog

What Is a Pneumatic Silencer and Why Do You Need One

Jan 07, 2026 Blog

How to Choose the Right Hex Head Plug

Jan 06, 2026 Blog

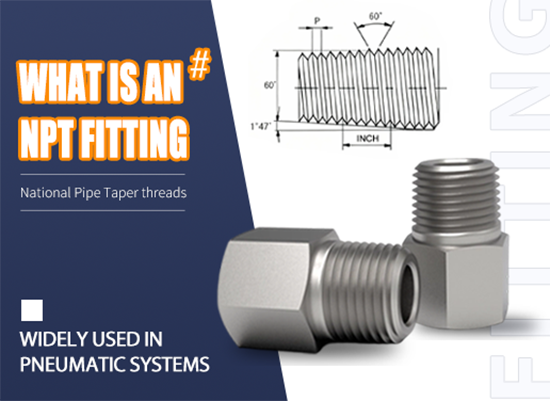

How to Measure NPT Threads Accurately on a Fitting

Dec 23, 2025 Blog

How to install compression fitting on copper pipe

Mar 10, 2025 Blog

Multi-Row Pu Hose Customization

Mar 10, 2025 Blog

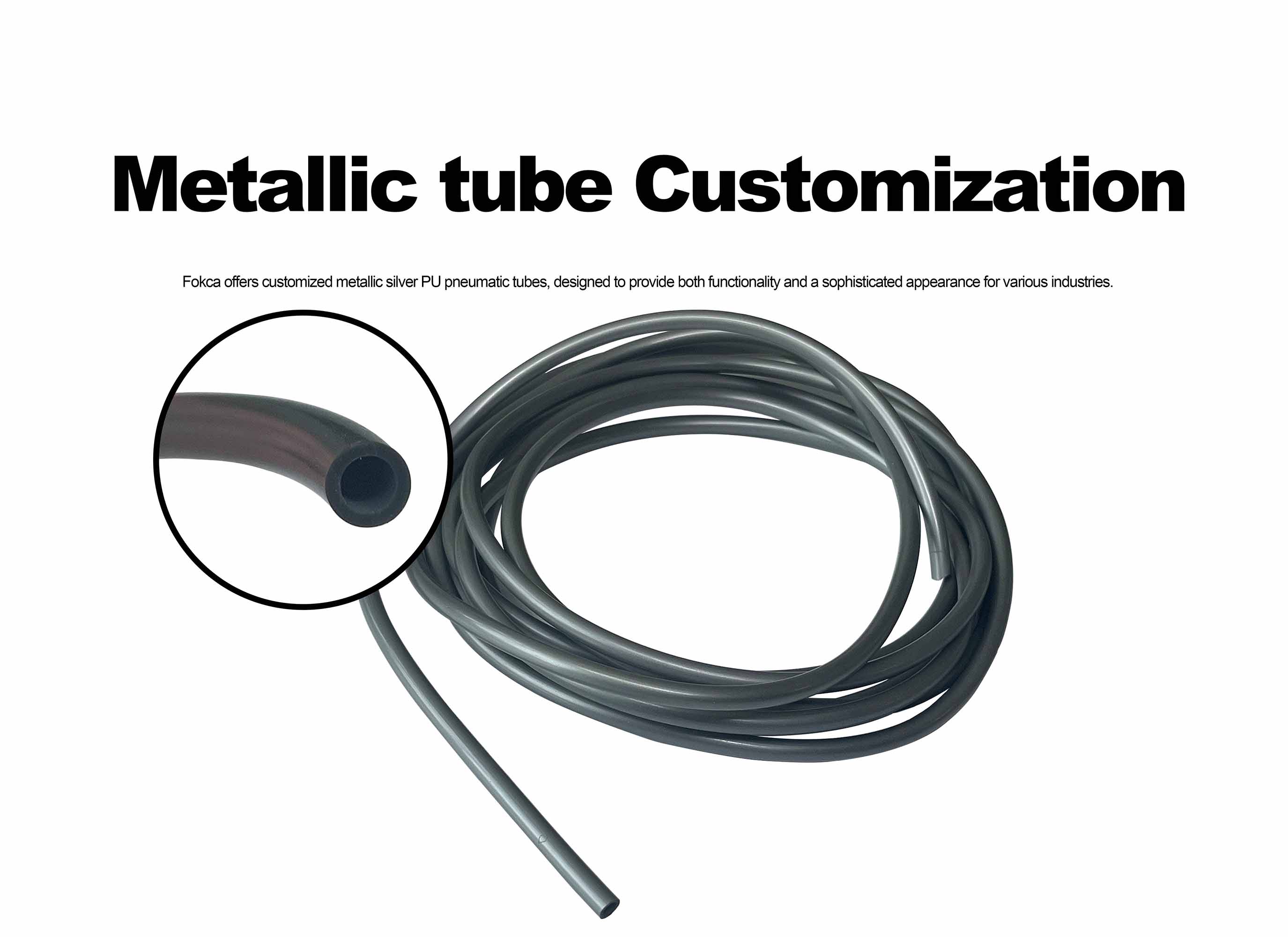

Metallic tube Customization

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap