Jan 12, 2026

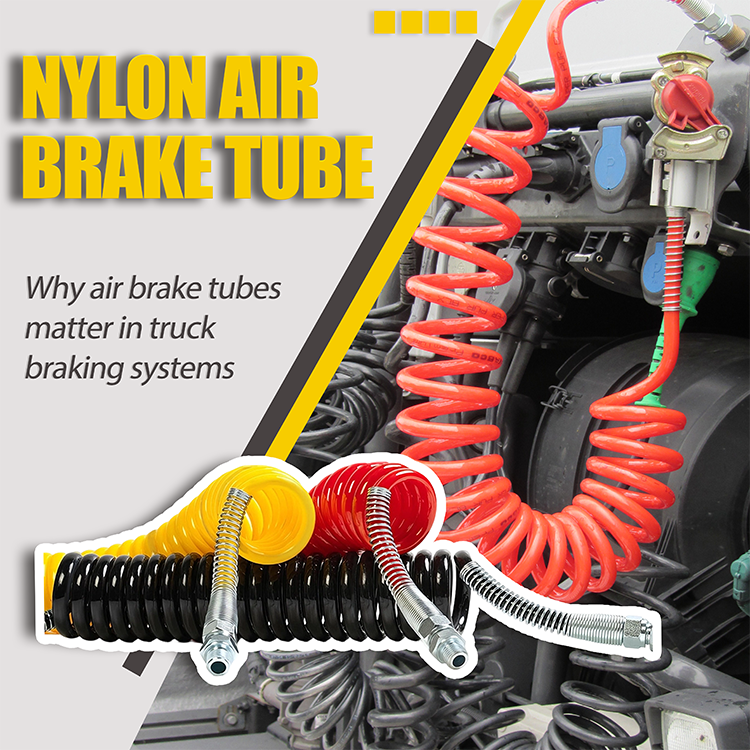

In a heavy-duty truck, few components work under harsher conditions than the air brake tube. It operates outdoors year-round, carries high-pressure compressed air, and plays a direct role in whether a vehicle can stop safely. For fleets, equipment engineers, and distributors, understanding how an air brake tube is designed, specified, and selected is not a minor technical detail—it directly affects braking response, reliability, and long-term operating cost.

In modern commercial vehicles, air brake tubes are most commonly used to transmit compressed air from reservoirs to brake valves and actuators. Among the various forms, air brake coiled hose are widely adopted because they accommodate movement between the tractor and trailer while maintaining stable air flow under pressure.

Unlike general pneumatic tubing used inside machinery, an air brake tube works as part of a safety-critical system. When a driver presses the brake pedal, compressed air must reach the brake valve and chambers instantly and consistently. Any delay, leakage, or deformation in the tube affects braking response.

In real-world trucking operations, these tubes are exposed to vibration, road debris, UV radiation, oil mist, and wide temperature swings. A standard industrial hose may perform well in a factory, but it often fails prematurely on a truck chassis. This is why air brake applications demand tubing with high pressure resistance, excellent weatherability, and strong abrasion resistance, rather than simple flexibility alone.

A nylon air brake tube functions as a pressurized conduit between air tanks, relay valves, and brake actuators. When compressed air is released from the reservoir, it travels through the tube to the brake valve, where pressure is modulated and distributed to the braking system.

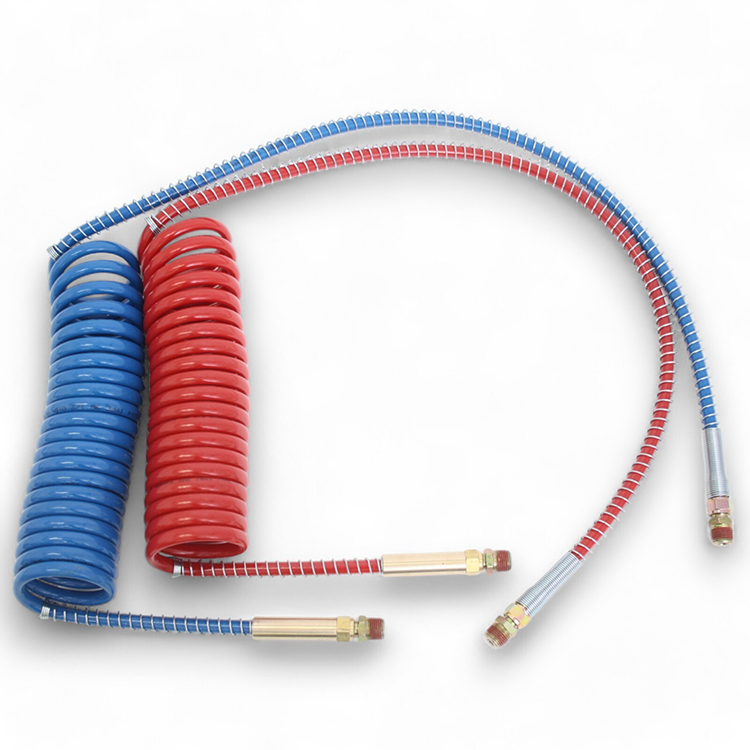

For tractor–trailer combinations, air brake coiled hose assemblies are commonly used. The coiled structure allows extension and retraction during turning and coupling without kinking or excessive stress. The straight tail sections on both ends—often referred to as short tail—ensure secure connections to fittings while keeping bending away from the coupling point.

This combination of coil elasticity and straight-tail stability is essential in preventing fatigue failure during repeated driving cycles.

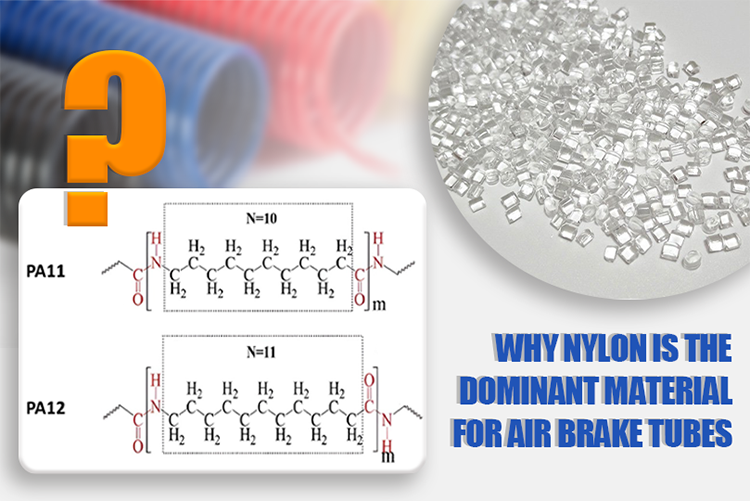

Among available materials, nylon tube (typically PA11 or PA12) has become the industry standard for air brake systems. This is not accidental; it results from a balance of mechanical, environmental, and regulatory requirements.

Nylon air brake tubes offer:

1.High working pressure and burst strength, suitable for truck air systems typically operating at 8–12 bar

2.Low air permeability, maintaining stable pressure over long distances

3.Excellent resistance to oil, fuel mist, and road chemicals

4.Strong abrasion resistance against frame contact and road debris

5.Good performance in low and high temperatures, supporting outdoor use across climates

Compared with rubber hoses , nylon tubes maintain dimensional stability under pressure and are less prone to swelling or aging. Compared with polyurethane, nylon provides better long-term pressure retention and environmental resistance for brake applications.

Different sections of a truck braking system impose different mechanical demands. Choosing between straight tubing and coiled assemblies depends on movement, space, and connection frequency.

| Application position | Recommended tube type | Key reason |

|---|---|---|

| Tractor–trailer connection | Air brake coiled hose | Accommodates movement and turning |

| Fixed chassis piping | Straight nylon air brake tube | Stable routing and pressure consistency |

| Areas with vibration | Coiled or protected straight tube | Reduces fatigue stress |

In practice, many vehicles use a combination: straight air brake tubes routed along the chassis, connected to air brake coiled short tail hoses at articulation points. This hybrid approach improves durability without increasing system complexity.

Because air brake tubes are part of a safety system, they are often subject to regulatory and industry standards. While requirements vary by region, common expectations include pressure rating, burst pressure margin, and material traceability.

For example, many nylon air brake tubes are designed with:

◆Working pressure significantly higher than normal operating pressure

◆Burst pressure several times the working pressure for safety margin

◆Compliance with recognized standards such as SAE J844 or equivalent regional specifications

From an engineering perspective, selecting a tube with adequate pressure margin is not optional. A tube that barely meets nominal pressure may pass initial testing but fail prematurely under vibration and temperature cycling.

Field failures in air brake systems are often traced back to inappropriate tubing selection rather than installation error. Typical issues include cracking, abrasion wear, and fitting pull-out.

Cracking usually occurs when tubing lacks sufficient cold-temperature flexibility or UV resistance. Abrasion failures result from insufficient wall hardness or poor routing. Pull-out failures are frequently linked to incompatible tube material and fitting design.

Using a nylon air brake tube with controlled dimensional tolerance and compatible fittings significantly reduces these risks. In demanding applications, protective sleeves or routing clips further extend service life without redesigning the system.

Although an air brake tube is a relatively small component in a truck, its role in braking safety is disproportionate to its cost. Choosing a properly engineered air brake coiled hose made from high-quality nylon reduces downtime, maintenance frequency, and safety risk over the vehicle’s service life.

For fleets, engineers, and distributors alike, treating air brake tubing as a reliability component rather than a consumable part leads to better system performance and stronger customer trust.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Jan 09, 2026 Blog

How EPU Tubing Improves Abrasion Resistance

Jan 08, 2026 Blog

What Is a Pneumatic Silencer and Why Do You Need One

Jan 07, 2026 Blog

How to Choose the Right Hex Head Plug

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 26, 2025 Blog

What Is Vacuum and What Is a Vacuum System

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap