Jan 07, 2026

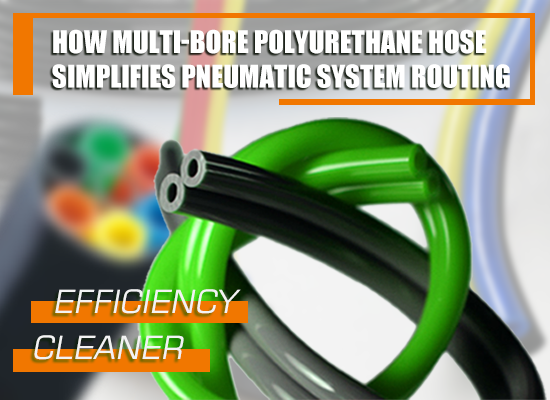

In industrial settings, efficient use of space is critical, especially in compact machinery or systems where every inch of space counts. Multi-bore polyurethane tubing (PUM) provides a distinct advantage in such environments, allowing for the efficient transport of multiple fluids or gases through a single compact hose. Compared to traditional polyurethane tubing, multi-bore PU hose offers greater flexibility in design, reduces the need for multiple tubes, and improves the overall performance of equipment. In this article, we will explore the key benefits of using multi-bore polyurethane tubing in tight spaces and compare it to standard PU tubing.

The primary advantage of using multi-bore polyurethane hose in compact devices is its ability to save space. Below are some key benefits:

1.Reduced Hose Count: In traditional systems, multiple individual hoses are often needed to carry different gases or fluids. With multi-bore PU tubing, multiple channels are combined into a single hose, reducing the number of hoses and fittings required. This minimizes clutter, simplifies installation, and improves the overall aesthetic and functionality of the equipment.

2.Optimized Routing: With fewer hoses to manage, the routing of lines in tight spaces becomes simpler and more efficient. Multi-bore tubing can be easily bent and routed around other components, ensuring the system stays organized and efficient without taking up valuable space.

3.Improved Performance: Fewer hoses mean less friction and resistance, which can improve the flow rates and efficiency of the system. In applications where space is tight, this improvement can lead to better system performance and energy efficiency.

While standard polyurethane tubing serves well in many applications, it doesn’t offer the same space-saving benefits as multi-bore PU hose. Here are the key differences:

1.Number of Hoses: In traditional setups, each fluid or gas type requires its own dedicated hose. This increases the number of tubes and fittings, taking up more space. Multi-bore tubing combines these hoses into one, saving both space and material costs.

2.Flexibility: Multi-bore polyurethane tubing is more flexible than multiple individual hoses, which can help engineers navigate around tight corners and reduce the need for additional fittings. Standard PU tubing, on the other hand, may require additional bends or connectors to fit into a compact space.

3.Complexity of Installation: Installing multiple individual hoses can become complex, especially in tight environments. The use of multi-bore PU tubing simplifies the installation process and reduces the chances of errors or leaks caused by multiple connections.

In industries such as automation, robotics, and machinery design, multi-bore polyurethane tubing plays a crucial role in optimizing space. Here are some common applications:

◆Automation Systems: In automated systems, where multiple fluids or gases are often required, multi-bore PU tubing provides a way to combine all these channels into a single, compact hose, reducing the number of fittings and allowing the system to work efficiently within confined spaces.

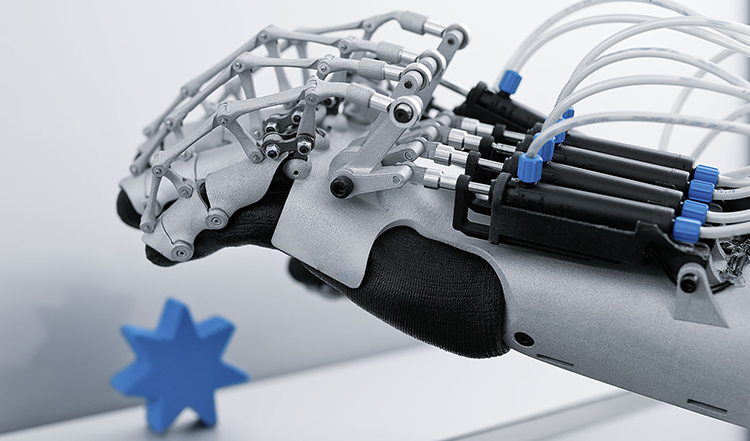

◆Robotics: Multi-bore polyurethane tubing is used extensively in robotic systems, where flexibility and compactness are essential. By using multi-bore tubing, manufacturers can streamline the design of the robot's hydraulic or pneumatic system, saving space and improving overall performance.

◆Pneumatic Controls: In pneumatic systems, multi-bore PU tubing is ideal for controlling multiple actuators or valves. The use of a single multi-bore hose eliminates the need for several individual hoses, making the system cleaner, easier to maintain, and more cost-effective.

Multi-bore polyurethane tubing is a game-changer for compact equipment, offering significant space-saving advantages compared to traditional PU tubing. By combining multiple channels into one flexible hose, it reduces the number of hoses, simplifies installation, and improves overall system performance. Whether you’re designing automated systems, robots, or pneumatic controls, FOKCA’s multi-bore PU tubing provides the durability, flexibility, and efficiency needed to optimize space and enhance functionality.

If you’re looking to optimize your equipment’s space utilization, contact us for high-quality multi-bore polyurethane tubing solutions.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

Jan 07, 2026 Blog

How to Choose the Right Hex Head Plug

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 22, 2025 Blog

Can Pneumatic Quick Couplings Be Used for Water

Dec 05, 2025 Blog

How to Repair a Damaged Hose Using a Hose Mender

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap