Jun 09, 2025

In pneumatic systems, the performance of pneumatic hoses directly impacts the efficiency, safety, and lifespan of the entire system. As the "transmission artery" connecting the air source, valves, and actuators, pneumatic tubing ensures safe and efficient media transmission, but also plays a role in preventing media leakage and environmental pollution.

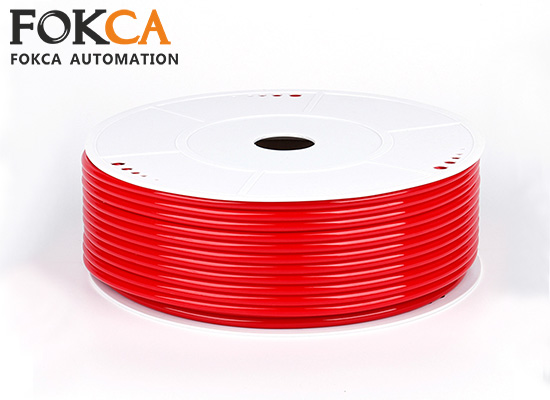

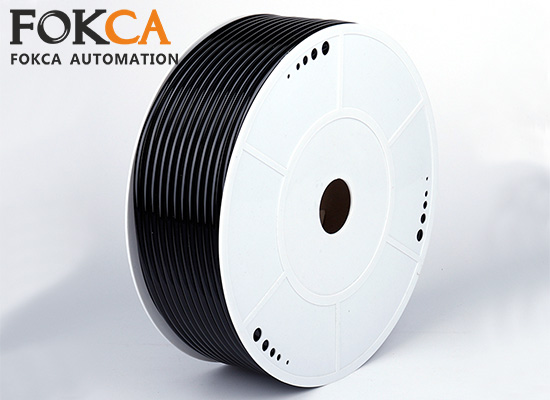

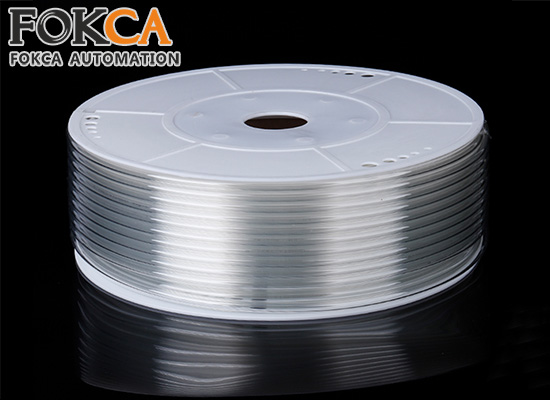

With the rapid development of automation technology and industrial equipment, the excellent properties of polyurethane pipes, such as flexibility, wear resistance, and compression resistance, have gradually been discovered and have become key materials for various system pipelines. Among them, Ester Based Polyurethane Tubing, as an important branch of the polyurethane material family, is a polyurethane based on ester chemical structure.

Compared to other types such as ether polyurethane, ester-based polyurethane tubings are more durable and wear-resistant, suitable for high-pressure, high-frequency bending, and complex working environments. They are commonly used in automation machinery, pneumatic tools, robot arms, spraying equipment, and other scenarios. Especially in equipment that operates at high speeds and experiences frequent vibrations, its stability and cost-effectiveness make it the preferred choice for pipeline layout.

Excellent Mechanical Properties

Ester Polyurethane Tubing has good tensile strength, tear resistance, and elastic recovery.under repeated deformation and impact,can maintain stable performance.

Superior Wear Resistance

Outstanding abrasion resistance,nearly 3 to 5 times that of natural rubber,making it ideal for transporting abrasive materials like slurry and granules.

Good Oil Resistance

Ester-based polyurethane exhibits excellent resistance to mineral oils, lubricants, and fuels,better than ether-based polyurethane.

Ester-based polyurethane tubing is a high-performance thermoplastic elastomer tubing. Compared to ether-based polyurethane, ester-based PU offers superior abrasion resistance, mechanical strength, and surface hardness — characteristics that are closely related to its material composition.

Polyol:Mainly composed of polyester polyols, determining the flexibility and mechanical strength of polyurethane.

Isocyanate:Commonly used TDI or MDI, providing cross-linked structures.

Chain Extender:Like butanediol, it can be used to adjust hardness and thermal properties.

Additive:Common ones include stabilizers, antioxidants, colorants, UV absorbers, etc., which enhance aging resistance and service life.

The manufacturing of ester based polyurethane pipes usually adopts extrusion molding process, and the specific process is as follows:

Raw material ratio and mixing:Weigh polyester polyols, isocyanates, and chain extenders according to the design formula; Mixing reactions are carried out in a closed system to form prepolymers.

Extrusion:After heating and melting the prepolymer, it is extruded into pipes through a single screw or twin-screw extruder and molded into pipes through a mold; Control the inner and outer diameter dimensions by adjusting the die structure.

Cooling pitching:The pipe is cooled and shaped by a cooling tank to maintain dimensional stability and surface smoothness.

Traction and cutting:Use a traction device to continuously pull out the pipe and automatically cut it according to the set length; Some products will be equipped with a rewinder for coil packaging.

Surface Treatment:Some high-end products can have an outer UV coating, anti-static coating, or anti slip texture treatment added.

Finally, it is necessary to control the product quality before putting it into use.

Performance comparison between PU ester based pipes and ether based polyurethane pipes. Due to its unique chemical structure, ester based polyurethane pipes have high wear resistance and mechanical strength, but poor water solubility resistance.

| Performance Indicator | Ester-Based Tubing | PU Ether-Based Tubing |

| Abrasion Resistance | Excellent | Good |

| Mechanical Strength | High | Moderate |

| Hydrolysis Resistance | Poor | Excellent |

| Oil Resistance | Fair | Excellent |

| Chemical Resistance | Good | Fair |

| Flexibility | Good | Better |

| Operating Temperature Range | -20°C to 60°C | -40°C to 80°C |

Excellent Abrasion Resistance

Due to its strong intermolecular structure and higher surface hardness, ester-based PU offers superior wear resistance. It is ideal for applications involving high-frequency movement, pneumatic slides, robotic arms, and dusty environments—ensuring longer service life.

Outstanding Mechanical Strength

PU ester tubing exhibits higher tensile strength, tear resistance, and pressure durability compared to ether-based types. This makes it suitable for high-pressure air delivery, dynamic mechanical parts, and industrial automation requiring robust performance.

Good Chemical Resistance

Ester-based PU resists many industrial chemicals such as oils, alcohols, and cleaning agents. It is suitable for factory automation, paint spraying systems, and chemical air transport applications.Cost-Effective with High Value

Compared to ether-based PU, ester-based materials are generally more affordable, offering a cost-performance advantage in environments that do not demand high hydrolysis resistance.

Smooth Surface and Easy Maintenance

The tubing has a smooth and dense surface, which makes it less prone to dust accumulation and easier to clean—ideal for use in packaging or food machinery where hygiene is important.

Ester based PU pipes are commonly used for gas source transmission in pneumatic systems, suitable for various cylinders, control valves, quick couplings, mobile slide systems, etc.

◆ Industrial robot pneumatic arm

◆ Drag chain system and pneumatic actuator

◆ Control unit for intelligent manufacturing production line

Some food grade ester based PU pipes can use formulations that comply with FDA or EU 10/2011 regulations for food contact materials, suitable for oil-free, dry gas, or auxiliary transport systems:

◆ Pneumatic component connection of food packaging machinery

◆ Cleaning and drying system for beverage bottling line

◆ Pneumatic operating system for automatic sorting device

In some low-pressure non liquid transmission environments, PU ester based tubing can be used for gas or vacuum transmission lines in medical or laboratory equipment:

◆ Pneumatic drive unit for medical automatic detection equipment

◆ Laboratory gas control module

◆ External auxiliary pipeline of ventilator

Suitable for air pressure control or paint assist pipelines in spray painting robots, spray rooms, and electrostatic precipitators:

◆ Vehicle body spraying line air supply pipe

◆ Spray powder conveying air pipe

◆ Industrial dust removal pulse valve auxiliary gas path

In high-speed packaging or printing equipment, PU pipes are connected to components such as vacuum generators, robotic arms, and quick switching air valves to undertake frequent actions and airflow switching tasks:

◆ Automatic labeling equipment

◆ High speed boxing robot

◆ Air suction transfer platform

Tube Size Selection

The inner diameter determines the airflow capacity, while the outer diameter matches the joint to ensure sealing and installation safety.Select an inner diameter that meets the flow requirements of the pneumatic system, while matching the outer diameter of the joint.

Material Hardness

When space is limited and bending winding is required, choose low hardness; Choose high hardness models when pressure resistance and wear resistance are required.

Operating Temperature

The standard temperature resistance range for PU ester based pipes is -20 ℃~60 ℃, and can reach up to 80 ℃ in the short term. Long term over temperature use can cause hardening, cracking, discoloration, and even leakage.Confirm the operating environment temperature and avoid long-term operation under high/low temperature limits.

Environmental Conditions

Fully evaluate the surrounding environment and choose special coatings or composite pipes if necessary.

In dry and high friction conditions, ester based PU can be used;

It is not recommended to use it in damp and frequently exposed to water conditions;

In a corrosive environment, it is necessary to consider whether chemical resistant materials have been added.

Special Requirements

Clarify industry compliance requirements and check if the pipes have relevant certifications.If used in sensitive fields such as food, medical, electronics, etc., food grade ester based PU pipes that comply with FDA, EU, RoHS and other certifications should be selected.

Regular Inspection

Before and after each use, thoroughly inspect the ester-based polyurethane tubing include Pay particular attention to bent sections and high-friction areas and Ensure all connections between the tubing and pneumatic components remain leak-free to prevent pressure loss from loosening.

Cleaning & Storage

After use, blow the inside of the polyurethane pipe with dry compressed air to prevent residue accumulation.When not in use for a long time, it should be stored in a coiled manner, avoiding direct sunlight, extreme temperatures, and humid environments.

Chemical Resistance Precautions

Ester Based Polyurethane has excellent oil resistance, but it is still necessary to avoid contact with strong acids, bases, or ester solvents when using hydraulic systems.

Pressure & Temperature Management

The work pressure shall not exceed the rated value. Although polyurethane pipes can withstand high temperatures, prolonged exposure to high temperatures can cause damage to the pipes.

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap