Jul 08, 2025

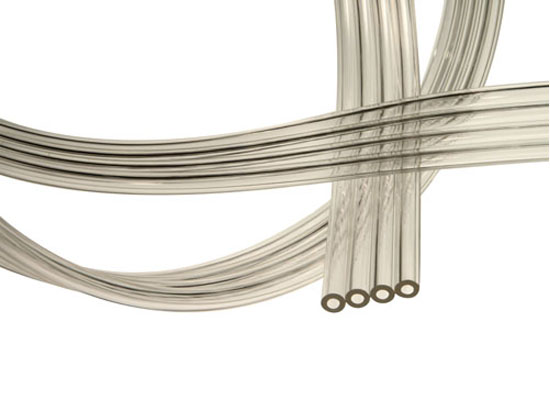

Parallel Polyurethane Tubing, also known as Parallel PU Pipe,has become increasingly vital across industries due to its exceptional flexibility, durability, abrasion resistance, oil resistance, and chemical resistance. With advancements in automation and dynamic motion systems, traditional spiral-reinforced PU hoses often fail to meet the demands of high-flexibility, high-pressure applications. This is where parallel-reinforced PU tubing stands out - its unique parallel reinforcement structure delivers superior performance compared to conventional designs.

Parallel PU Pipe, is typically made by combining multiple PU air tubes through co-extrusion or thermal bonding processes to form a side-by-side structure. It offers various functions such as fast transmission, a neat appearance, and tangle prevention. This structure design makes polyurethane tubing especially suitable for industrial systems that require the simultaneous delivery of multiple air channels, helping to simplify wiring and improve overall equipment layout efficiency.

Enhanced Abrasion Resistance:Multi-row polyurethane tubes share the load under frequent friction or mechanical movement, helping to prevent excessive wear on any single surface.

Excellent Flexibility:Allows bending without kinking, making it easy to install in compact or curved pathways.

Optimized Space Utilization:Multiple air channels are combined into a compact unit, significantly reducing the required installation space. Ideal for equipment with limited space or complex layouts.

Improved Wiring Efficiency:Enables simultaneous installation of multiple tubes, simplifying the overall layout. Reduces installation and maintenance time and labor costs.

Neat and Tangle-Free Layout:The parallel structure keeps hoses aligned and organized, preventing tangling or misrouting.

Pneumatic Control Systems:Can connect multiple actuators or valves to enable efficient multi-channel air distribution in automation equipment.

Robotic Arm Cable Routing:Used to organize air tubes and signal cables along robotic arms, ensuring flexibility, a neat layout, and reduced interference.

Integrated Cable and Air Tube Routing:Suitable for systems requiring the simultaneous routing of cables and air tubes, simplifying installation and reducing space usage.

Medical Equipment:Applied in medical gas systems and devices that require precise, clean, and multi-channel air delivery, such as ventilators or laboratory automation equipment.

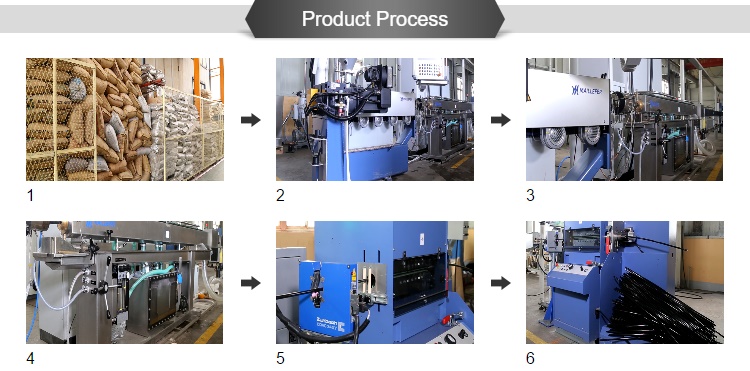

Here are the common manufacturing processes for multi-row PU tubes. The quality of multi-row PU tubes produced varies depending on the manufacturing process used, which in turn affects their suitability for different industry applications.

Multiple polyurethane air tubes are simultaneously extruded through a multi-hole die at high temperature, and bonded together through thermal fusion during the extrusion process.

Features:

Uniform wall thickness and strong bonding

Suitable for long-term fixed installations, not easily separated

High production efficiency with consistent forming quality

Single PU tubes are first extruded separately, then fused together into a single unit using thermal bonding equipment at a controlled temperature.

Features:

Allows for separable parallel tube structures

Flexible processing, suitable for customization

High bonding strength, ideal for dynamic applications

After forming, the tubing is processed according to customer requirements.

Features:

Fixed-length cutting

End chamfering or flaring

Connector assembly (optional)

Key inspection items include:

Dimensional consistency

Bonding strength testing

Air tightness and pressure resistance testing

Bending radius and flexural endurance testing

We focus on the research and production of Parallel PU Hose, include Straight through multi row and coil multi row parallel PU pipes.Fokca can provide flexible customized services according to customers' different working conditions.

The specifications for customizing Parallel PU Hose include:Pipe diameter size and color, parallel quantity, pipe spacing and arrangement structure, temperature resistant, flame retardant, oil resistant special formula materials, printing, brand identification, exclusive packaging and other related content

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap