Jun 04, 2025

In modern wiring solutions, a series of material requirements such as heat shrinkability, abrasion resistance, and insulation are emphasized. Polyolefin heat shrink tubing is one of the key materials for protection, insulation, and sealing. With its excellent performance, reliable insulating capability, and wide range of applications, polyolefin heat shrink tubing has become the preferred choice in industries such as industrial manufacturing, power systems, electronics, and automotive sectors.

Polyolefin Tubing is a type of heat shrink tube made from polyolefin-based materials. Its most notable feature is its ability to shrink when heated. In addition, it offers multiple functions such as insulation, waterproofing, and corrosion resistance. “Heat shrink” refers to the tubing's capability to contract upon heating, tightly wrapping around the protected object to provide a secure and durable covering.

The most prominent feature of Polyolefin tubing is its ability to shrink when heated, tightly wrapping around the target object to provide electrical insulation and sealing.Essentially, Polyolefin tube is just a kind of protective pipe type.

◆ Excellent electrical insulation performance

◆ Superior corrosion resistance, abrasion resistance, and flame retardancy

◆ Compliance with environmental certifications such as RoHS and UL

◆ Widely used in terminal sealing, cable management, battery protection, and other applications

Polyolefin Tubing can be classified into the following types based on structural and performance differences.Mainly include PP tubing and PE tubing.Two types have structure,function,and application difference.Polyethylene Tubing include LDPE tube and LLDPE tube.Also,two types have structure,function,and application difference.

The crystalline structure of PE pipes is relatively loose, the molecular structure is simpler, there are more branches, and the arrangement is not tight enough.

Feature:Soft texture, better toughness, lower temperature resistance, better corrosion resistance, color ranging from milky white to semi transparent.

Applicaiton:Suitable for environments with high flexibility requirements and corrosion resistance, such as water pipes, chemical liquid transportation, and flexible pipelines.

LDPE:It is a PE pipe with better flexibility and toughness, and lower stretchability.

LLDPE:It is a PE pipe with higher strength and better puncture resistance, but poor flexibility.

PP pipes have high crystallinity, tightly arranged molecular chains, a more regular structure, and a side group structure.

Feature:Strong rigidity, high hardness, more stable structure, better heat resistance, inferior chemical resistance to PE, semi transparent or milky white color, smooth surface.

Applicaiton:Suitable for applications that require rigidity and heat resistance, such as industrial pipelines and thermal fluid transportation.

Heat Resistance: Can withstand high temperatures up to 125°C.

Insulation: High breakdown voltage, compliant with standards such as UL224.

Flame Retardancy: Typically rated at VW-1 flame retardant level, meeting safety requirements.

Shrink Characteristics: Begins to shrink at approximately 70°C and completes shrinkage around 125°C.

Flexibility: Soft and conformable, able to adapt to irregular surfaces.

| Material | Polyolefin Tubing | PVC |

| Property | High Heat Resistance | Medium Heat Resistance |

| Property | High Heat Resistance | Medium Heat Resistance |

| Environmental Certification | Usually Certified | Partially Certified |

| Cost | Medium | Low |

| Common Application | Industrial, Automotive, Electronic Equipment | Civil Cables, Household Appliances |

By comparing the data in the above table, it can be concluded that Polyolefin Tubing is an ideal material that strikes a balance between performance, cost, and versatility.

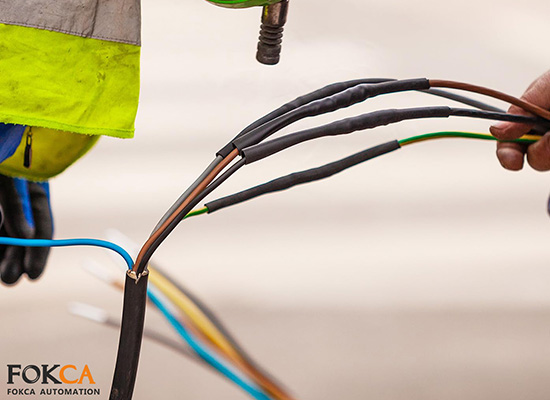

Electronic Component Protection: After heat shrinking, Polyolefin Tubing tightly adheres to cables, safeguarding solder joints or connectors.

Battery Encapsulation: It provides heat shrink protection for lithium batteries and power battery packs.

Automotive Wiring Harnesses: Used for covering engine compartments, areas behind the dashboard, and connectors in automotive applications.

Communications and Industrial Automation: Suitable for complex environments such as PLC cabinets and communication lines.

Medical and Military Sectors: Optional clean-grade or military-standard versions are available for these specialized fields.

Whether during cable installation and operation or in transportation, storage, and temporary on-site protection, specialized Tubing Cable Polyolefin protective kits are required to prevent cables from being cut or damaged.

Installation Steps:

Select an appropriate size of heat shrink tubing.

Pre-slide the heat shrink tubing onto the cable or component.

Apply even heating using a heat gun.

The tubing will begin to shrink and conform tightly to the object.

After cooling, inspect to ensure a complete and secure fit.

Precautions:

It is recommended to control the heating temperature within the range of 110–135°C.

Avoid overheating to prevent scorching or damage to the conductor.

Using an industrial heat gun is recommended for higher efficiency.

Store the tubing away from direct strong sunlight and high-humidity environments.

Q1: Does Polyolefin Tubing shrink when heated?

A: Yes, it does. Polyolefin Tubing is a type of heat shrink material that automatically reduces in diameter and conforms tightly to the protected object when heated to a certain temperature.

Q2: Can it be used in automotive or outdoor applications?

A: Absolutely. Polyolefin Tubing has excellent temperature resistance, oil resistance, and UV resistance, making it suitable for automotive, outdoor communication, and other similar environments.

Q3: What is the difference between double-walled and single-walled Polyolefin Tubing?

A: Double-walled Polyolefin Tubing contains a hot melt adhesive layer inside, which is suitable for applications requiring sealing, waterproofing, and corrosion protection. Single-walled tubing is more suitable for general insulation and identification purposes.

Q4: Can it be used in medical or high-cleanliness environments?

A: Yes, it can. Some manufacturers offer medical-grade, dust-free certified versions of Polyolefin Tubing. Please select the appropriate product based on your certification requirements.

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap