Sep 24, 2025

Wondering if polyurethane tubing can moonlight as a fuel line hero? In this snappy guide, we size up what fuel lines secretly demand from their tubing, peek at how polyurethane actually behaves when it meets gasoline or diesel, and even pit it against heavyweights like nylon and PTFE-lined hoses. Stick around and you'll not only get the facts but also discover snag top-quality polyurethane tubing for fuel applications right at Fokca.

Fuel lines operate in a chemically aggressive, high-temperature, and pressurized environment. As a result, tubing materials for fuel delivery systems must meet several stringent requirements:

Chemical Resistance to Fuels and Additives:Tubing must resist gasoline, diesel, ethanol blends (E10–E85), biodiesel, and the various detergents or anti-corrosion agents in modern fuels. Poor compatibility leads to swelling, softening, cracking, or fuel contamination.

High Temperature and Low Temperature Stability:Under-hood temperatures can exceed 120 °C (248 °F), while vehicles in cold climates may see −40 °C (−40 °F). A suitable tubing material must retain flexibility and structural integrity across this entire range.

Pressure Resistance and Burst Strength:Fuel injection systems, especially direct injection, can exceed 3–5 bar (or higher). Tubing must maintain dimensional stability under constant pressure without leaking or collapsing.

Permeation Control (Low Fuel Vapor Loss):Modern emission regulations (EPA, CARB, EU) limit evaporative fuel loss. Tubing materials must have low permeability to hydrocarbons to meet these standards.

Mechanical Durability and Flexibility:The tube should resist vibration, abrasion from engine components, and repeated bending without fatigue cracking. This extends service life and reduces maintenance.

Compliance with Automotive Standards:Materials often must comply with SAE J30, SAE J2260, ISO 15500, or OEM specifications for fuel hoses and lines.

Ease of Installation and Connection:Tubing should be compatible with standard fittings, clamps, and quick-connect couplers, enabling secure assembly on production lines.

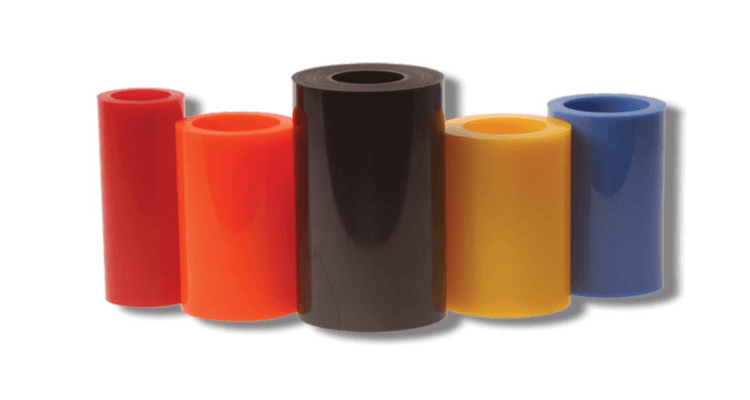

Polyurethane (PU) tubing offers excellent chemical resistance and outstanding weatherability, distinguishing it from many other thermoplastics and often making it a strong candidate for fuel-line applications.

In practice, many grades of pu tubing exhibit excellent resistance to gasoline, diesel, kerosene, and common petroleum-based oils — they resist softening, cracking, and abrasive wear better than many elastomers — so polyurethane hose is frequently used for low-pressure fuel return lines, drain lines, and non-critical fuel transfer in industrial and small-engine contexts. That said, real-world performance depends on formulation: polyether-based PUs generally offer superior hydrolysis resistance and low-temperature flexibility, while polyester-based PUs can give higher mechanical strength but may be more sensitive to long-term hydrolytic attack.

In industrial and pneumatic applications, choosing the right tubing material is critical for system efficiency, safety, and longevity. Beyond standard polyurethane tubing, alternative materials such as nylon tubing and PTFE (Polytetrafluoroethylene) lined hose offer specific advantages that meet specialized operational requirements.

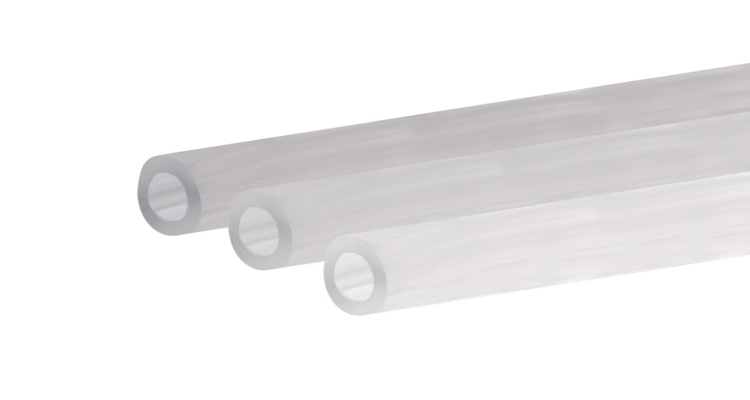

Nylon tubing is a versatile, high-performance material widely used in pneumatic, hydraulic, and fluid transfer systems. It is engineered to withstand high pressure, resist abrasion, and maintain stability under fluctuating temperatures.

Key Features:

1.High Strength and Durability: Nylon tubing offers excellent mechanical strength, making it suitable for pressurized systems and industrial automation.

2.Temperature Resistance: Typically operable from -40°C to 80°C (-40°F to 176°F), ensuring reliability in diverse environments.

3.Chemical Compatibility: Resistant to oils, fuels, and many industrial chemicals, preventing premature degradation.

4.Lightweight: Easy to handle and install, reducing overall system weight.

5.Flexibility: Offers moderate flexibility, suitable for complex routing without kinking.

Applications:

Pneumatic air lines for automation equipment.

Fluid and chemical transfer in industrial facilities.

Protective casing for sensor or instrument wiring.

PTFE lined hoses combine the chemical resistance and thermal stability of PTFE with the flexibility of reinforced hose constructions. These hoses are ideal for aggressive chemical handling, high-temperature fluids, and applications requiring non-contaminating flow paths.

Key Features:

1)Exceptional Chemical Resistance: PTFE is virtually inert to nearly all chemicals, acids, and solvents.

2)High Temperature Tolerance: Can operate continuously at temperatures up to 260°C (500°F).

3)Low Friction Surface: Ensures smooth flow of liquids and reduces clogging or fouling.

4)Flexible Construction: The reinforced exterior provides durability while maintaining manageable flexibility.

5)Non-Contaminating: PTFE lining prevents reactions between fluid and hose, essential in food, pharmaceutical, and chemical industries.

Applications:

Chemical transfer lines in industrial processing plants.

High-temperature fluid delivery systems.

Pharmaceutical and food-grade processing lines requiring non-reactive surfaces.

Looking for polyurethane tubing that can handle fuel without throwing a tantrum? Engineers and industry professionals know that not all tubing is created equal. At Fokca, our fuel-grade polyurethane tubing is built to last, resist chemical attack, and stay flexible even when the heat (or pressure) is on. No leaks, no surprises—just smooth, reliable flow every time.

Backed by over 15 years of experience, Fokca combines advanced production technology with strict 6S management. Our tubing meets ISO9001, TS16949, CE, FDA, and ROHS standards, making it a trusted choice for automotive fuel lines, industrial fuel transfer, and pneumatic fuel applications. When you need tubing that performs like a pro, Fokca has your back—without any drama. You are welcome to contact us at any time.

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap