Jan 14, 2026

In many industrial liquid transfer systems, tubing selection is often based on chemical compatibility and nominal pressure ratings. However, in real operating conditions—especially when handling coolants, lubricating oils, and low-viscosity industrial fluids—the structural behavior of the tube under pressure becomes equally critical. This is where PUB Braided Polyurethane Tube demonstrates clear advantages over standard polyurethane tubes pipe PU.

Unlike compressed air, liquids are largely incompressible. Any dimensional change in the tube—particularly radial expansion—directly affects system pressure, flow stability, and response time. In liquid circuits such as coolant delivery or oil lubrication lines, even minor tube deformation can lead to pressure loss, uneven flow distribution, or delayed system response.

Standard PU polyurethane tubes are flexible and easy to install, but their elastic nature means that under continuous liquid pressure, the tube wall may expand more than expected, especially during pressure surges or pump start-up cycles.

A common misconception is that if a PU tube meets the required pressure rating, it is suitable for liquid transfer. In practice, pressure resistance and pressure stability are not the same.

1.Ordinary PU tubes may meet static pressure requirements but still exhibit noticeable expansion.

2.Repeated expansion and recovery can cause gradual dimensional fatigue.

3.Flow rate consistency becomes harder to maintain in long or branched pipelines.

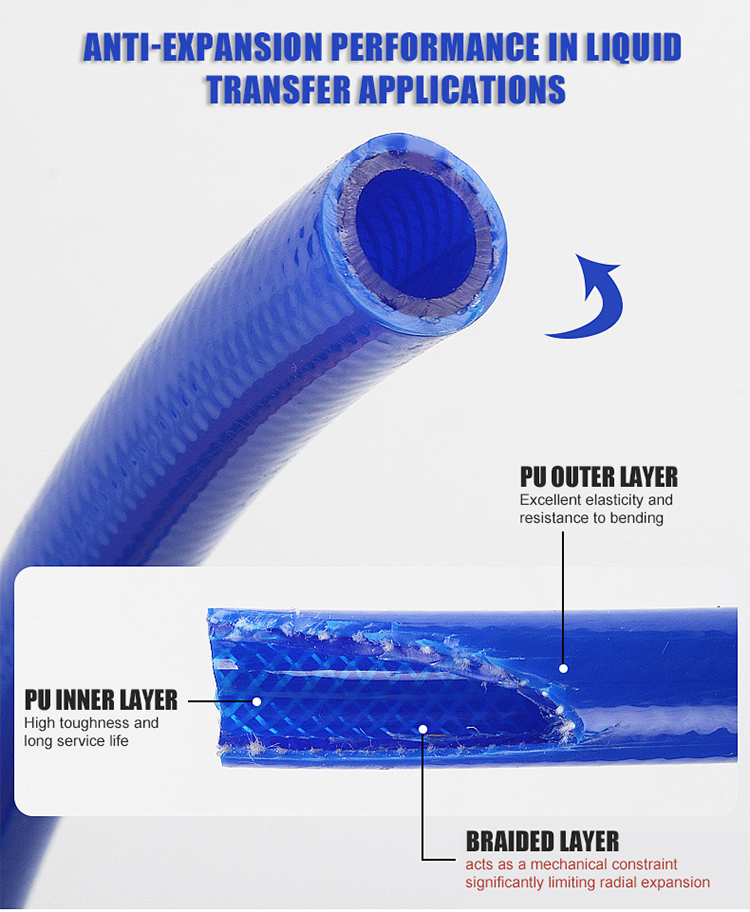

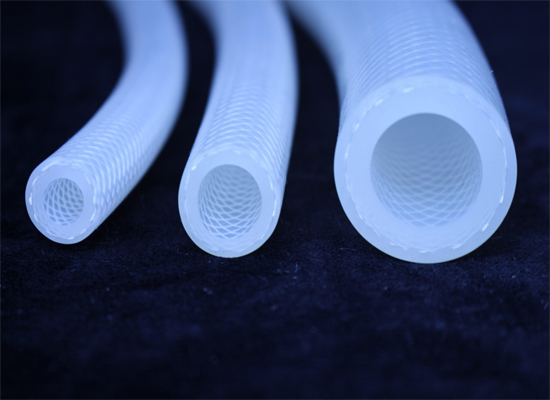

A PUB Braided Polyurethane Tube integrates a reinforcing braid—typically polyester fiber—between the inner and outer PU layers. This structure fundamentally changes how the tube responds to internal liquid pressure.

The braided layer in a PUB Braided Polyurethane Tube acts as a mechanical constraint, significantly limiting radial expansion. This provides tangible benefits in liquid systems:

1.Stable inner diameter, even under fluctuating pump pressure

2.Reduced volumetric expansion, improving flow predictability

3.Better pressure transmission efficiency from pump to end point

For liquids such as cooling fluids or lubricating oils, this stability helps maintain consistent delivery rates, which is especially important in CNC machines, automated lubrication systems, and thermal management circuits.

The structural differences translate directly into performance differences, as shown below:

| Performance Aspect | Ordinary PU Tube | PUB Braided Polyurethane Tube |

|---|---|---|

| Pressure-induced expansion | Noticeable | Highly controlled |

| Flow stability | Moderate | High |

| Resistance to pressure surges | Limited | Excellent |

| Suitability for liquid media | Conditional | Well suited |

| Long-term dimensional stability | Average | Superior |

Based on industry application data and material behavior analysis.

For systems operating continuously or under cyclic pressure, these differences have a measurable impact on reliability and maintenance intervals.

Cooling liquids and lubricating oils are commonly circulated by pumps that generate pulsating pressure. In such environments:

◆Expansion in ordinary PU tubes absorbs part of the pump energy.

◆Pressure fluctuations become amplified downstream.

◆Flow balance between parallel lines becomes harder to control.

The PUB Braided Polyurethane Tubeminimizes these effects by maintaining structural integrity under dynamic pressure. This makes it particularly suitable for machine tools, molding equipment, and centralized lubrication systems where consistent fluid delivery is a functional requirement rather than a preference.

Liquid transfer often introduces additional wear factors, including oil additives, fine particles, and temperature variation. The inner layer of PUB Braided Polyurethane Tube is typically formulated with controlled hardness, balancing flexibility and abrasion resistance.

Combined with the braided reinforcement, this structure reduces long-term deformation and inner-wall wear, helping the tube maintain both pressure performance and flow characteristics over extended service life.

FOKCA designs PUB Braided Polyurethane Tube with a focus on real industrial liquid transfer conditions. Instead of maximizing stiffness alone, material hardness and braid density are selected to achieve pressure stability, flexibility, and durability in balanced proportions.

This approach allows FOKCA to support distributors, OEM customers, and end users who require tubing solutions that perform consistently across different machines, fluids, and operating cycles—especially in applications where ordinary PU tubes approach their functional limits.

For liquid transport involving coolants, lubricating oils, or pressurized industrial fluids, tubing should be evaluated not only by pressure rating but also by anti-expansion capability and flow stability. In many such cases, PUB Braided Polyurethane Tube offers a more reliable and predictable solution than standard PU tubing.

This structural advantage explains why braided PU tubes are increasingly specified in modern industrial liquid systems where performance consistency and operational reliability are essential.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Jan 06, 2026 Blog

How to Measure NPT Threads Accurately on a Fitting

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic Fittings

Sep 24, 2025 Blog

Can polyurethane tubing be used for fuel lines?

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

May 14, 2025 Blog

What is Rubber Hose?

May 21, 2025 Blog

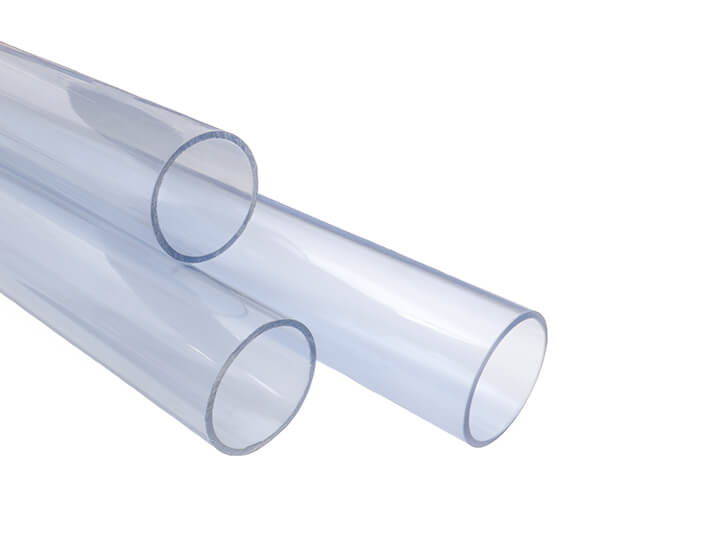

The Difference Between Flexible and Rigid PVC PipeLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap