May 14, 2025

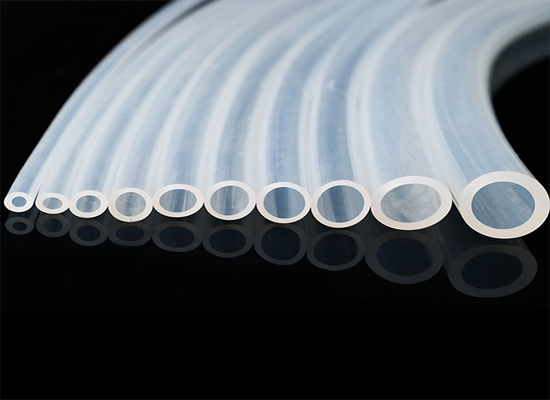

Rubber hose is a hollow tubular product made from natural or synthetic rubber. It features softness, good elasticity, pressure resistance, and wear resistance. Rubber hoses are commonly used for transporting liquids, gases, or granular materials, making them essential connection and transmission components in industry, agriculture, and everyday life.

In today's blog, You can learn more about the definition, structure, types, advantages, and other aspects of rubber hose:

• What is a rubber hose

• The structure of a rubber hose

• The main types of rubber hoses

• The advantages of rubber hoses

• Applications of rubber hoses

It is commonly used to transport liquids, gases, water, or granular materials and serves as a widely used connection and transmission component in industry, agriculture, and daily life.

Although the structure of a rubber hose appears simple, it is typically composed of multiple precisely engineered layers, each serving a specific function to ensure sufficient strength, flexibility, pressure resistance, and chemical resistance.

Inner Layer: This layer comes into direct contact with the medium and is mainly responsible for transporting and sealing the medium. It is usually made of natural rubber or rubber materials that can resist high temperatures and oil.

Reinforcement Layer: This layer provides the hose with pressure resistance, tensile strength, and impact resistance.

Outer Layer: This layer protects the hose from external damage caused by environmental factors such as sunlight, chemicals, and abrasion.

Rubber hoses can be categorized in various ways based on their use, structure, and materials:

By application

| Type | Application Description |

|---|---|

| Water Hose | Used for transporting cold or hot water; commonly found in gardening and household applications. |

| Air Hose | Mainly used with air compressors, pneumatic tools, and similar equipment. |

| Oil Hose | Oil-resistant and suitable for transporting diesel, gasoline, and other oil-based media. |

| Food Grade Hose | Used for transporting drinking water, milk, beer, etc., and meets high hygiene standards. |

| Chemical Hose | Resistant to acid and alkali corrosion; ideal for use in the chemical industry. |

| Automotive Hose | Includes radiator hoses, fuel hoses, and others specifically designed for vehicles. |

By Structure

Single layer rubber hose

Multi layer woven reinforced hose

Rubber hoses with metal fittings or quick connect devices

Excellent Flexibility : Can be bent and coiled easily, making installation and operation convenient.

Wear and Aging Resistance : The surface is resistant to abrasion, UV radiation, and aging caused by high or low temperatures

High Pressure Resistance : Especially in multi-layer reinforced hoses, which can withstand high working pressures.

Strong Chemical Resistance : Suitable for transporting various corrosive media such as acids, alkalis, and oils

Good Sealing Performance : Tight connections with excellent leak-proof capabilities, ideal for demanding industrial environments.

Industrial Manufacturing

Industrial-grade rubber hoses are not only used for conveying compressed air, but also for transferring chemicals, coolant lines, and connecting hydraulic systems.

Agriculture

In agriculture, rubber hoses are used in irrigation systems, pesticide spraying, and pump connections.

Construction

In the construction industry, rubber hoses are used to transport concrete and for high-pressure water cleaning applications.

Automotive

In the automotive sector, due to their excellent resistance to high temperatures and chemicals, rubber hoses are used for radiator hoses, fuel delivery, brake lines, and more.

Pharmaceutical and Food Industries

In the pharmaceutical industry, rubber hoses are used for fluid transfer in manufacturing equipment. In the food industry, they are used for beverage dispensing lines and other hygienic applications.

Home and Gardening

In household and gardening settings, rubber hoses are ideal for car washing, garden watering, and connecting to sprinklers and nozzles.

Rubber hoses are versatile, durable, and indispensable components in many systems. Shree Rubber Works specializes in manufacturing heavy-duty industrial rubber hoses designed for the toughest environments. Our hoses withstand extreme temperatures, high pressure, and abrasion. If you're looking for the best rubber hose manufacturer, feel free to contact us to discuss how we can assist you.

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap