Jan 22, 2026

In many automated production lines, pneumatic hoses are routed close to welding zones, furnaces, hot molds, or moving mechanical parts. A standard polyurethane hose may offer flexibility and abrasion resistance, but under flame exposure it softens quickly, collapses, and loses pressure integrity. This is whyPUFR flame-resistant hose often integrates an aluminum foil layer—not as decoration, but as a critical functional barrier that directly improves fire resistance and safety margins.

Polyurethane is a thermoplastic material. Even when modified with flame-retardant additives, its molecular structure will still soften, deform, and eventually melt when exposed to sustained heat. In real factory conditions, the danger is not only open flame but radiant heat, hot metal splashes, and oxygen-rich airflow that accelerates degradation. This is where a fire resistant flexible hose must rely on structural protection, not just material chemistry.

Aluminum foil is non-flammable, does not support combustion, and remains structurally stable at temperatures far beyond the softening point of PU. More importantly, it introduces a physical fire barrier that chemical additives alone cannot provide. When wrapped or laminated around a PU hose, aluminum foil becomes the first line of defense in a flame resistant hose cover system.

From an engineering perspective, aluminum foil contributes three essential protective mechanisms: oxygen isolation, heat management, and radiation reflection.

Combustion requires oxygen. Aluminum foil forms a continuous, low-permeability barrier that limits oxygen diffusion to the inner PU layer. Even if the outer surface is exposed to flame, the reduced oxygen supply significantly slows down polymer breakdown. This is one reason fire resistant hose pipe designs with foil layers achieve higher flame-retardant classifications than PU-only solutions.

In practical testing, hoses with aluminum foil layers show longer time-to-failure under direct flame exposure, maintaining air pressure long enough for emergency shutdown or fire suppression systems to activate.

While aluminum is often associated with high thermal conductivity in bulk form, thin aluminum foil behaves differently in composite structures. Instead of storing heat, it spreads localized thermal energy across a wider surface area. This reduces hot spots and delays the temperature rise of the inner PU tube.

The result is a measurable increase in:

1.Time before PU softening

2.Time before collapse or leakage

3.Overall fire endurance rating

This thermal delay is critical in applications such as robotic welding cells or steel processing lines where brief flame exposure is common but catastrophic hose failure must be avoided.

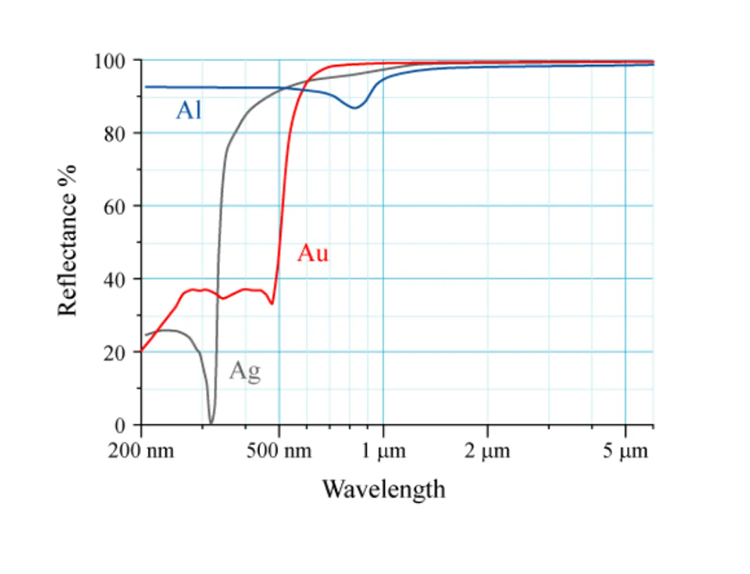

In many industrial fires or high-heat zones, radiant heat is more destructive than direct flame. Aluminum foil has excellent infrared reflectivity, allowing it to reflect a significant portion of radiant heat away from the hose core. This is especially valuable in installations near furnaces, heaters, or molten metal channels.

For equipment engineers, this reflective function often explains why gates flame resistant hose and similar premium designs consistently outperform basic flame-retardant hoses in long-term thermal aging tests.

| Feature | Standard PU Hose | PUFR Hose with Aluminum Foil |

|---|---|---|

| Flame contact tolerance | Low | High |

| Oxygen permeability | High | Very low |

| Radiant heat resistance | Minimal | Excellent |

| Time to softening | Short | Extended |

| Suitable for hot zones | No | Yes |

Data reference: Industrial hose fire testing reports from automation equipment manufacturers and material safety evaluations.

◆Robotic welding systems

◆Automotive assembly lines

◆Steel and aluminum processing equipment

◆Glass manufacturing machines

◆High-speed automated packaging near heating units

In these environments, a fire-resistant flexible hose is not a premium upgrade—it is a risk-control component.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Dec 12, 2024 Customer Case

Multi-Row Pu Hose Customization

Sep 10, 2023 Blog

How To Differentiate And Select Teflon Pipe?

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap