Jan 20, 2026

In pneumatic automation, speed control often looks simple on paper. Add a Throttle Valve, turn the adjustment screw, and the actuator slows down. Yet in real machines, engineers quickly discover an inconsistency: the same throttle valve pneumatic setup behaves very differently depending on whether the valve is installed at the cylinder inlet or the outlet. This difference is not accidental—it is rooted in the compressibility of air and the way pressure builds and releases inside a cylinder.

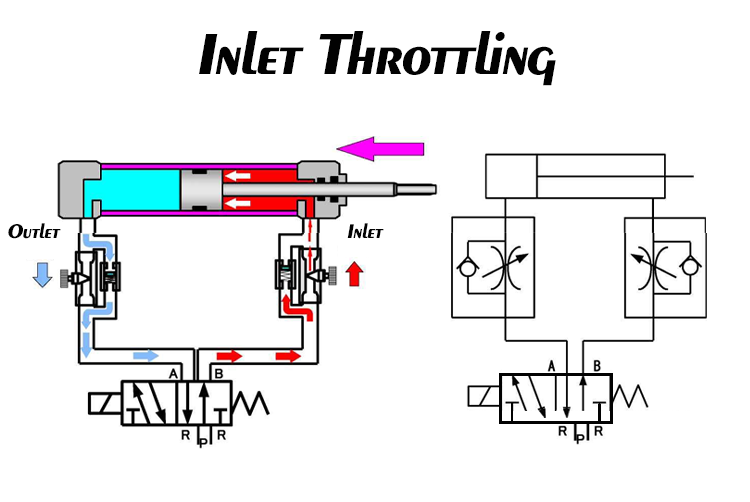

Unlike hydraulic oil, compressed air behaves like a spring. When air enters a cylinder chamber, it compresses before generating force. If the throttle valve actuator is installed on the inlet side, the incoming air is restricted, but the air already inside the chamber continues to expand and compress as the load changes. This often leads to speed fluctuation, especially when the external load varies.

From an engineering perspective, inlet throttling controls how fast pressure rises, not how smoothly air exits. As a result, piston speed becomes sensitive to load changes, seal friction, and even minor pressure variations in the air supply.

When the throttle valve is installed on the exhaust side, the situation changes fundamentally. Air enters the cylinder freely, allowing pressure to build quickly and consistently. The throttle valve pneumatic function then controls how fast air leaves the chamber, which directly governs piston speed.

This exhaust throttling approach creates a back-pressure effect that stabilizes movement. Even when the load fluctuates, the trapped air provides a cushioning effect that smooths motion. This is why, in most industrial automation equipment, outlet throttling is the preferred method for speed control rather than inlet restriction.

Although exhaust throttling is widely recommended, inlet throttling is not entirely obsolete. In very light-load applications, such as small pick-and-place units or spring-assisted actuators, inlet throttling can offer acceptable control with minimal components. It may also be used intentionally when a softer pressure buildup is required to protect delicate mechanisms.

However, these are controlled exceptions. In general production machinery, relying on inlet throttling alone often leads to complaints that “the speed can’t be adjusted smoothly,” even when the throttle valve itself is functioning correctly.

Beyond inlet versus outlet placement, the physical distance between the throttle valve and the cylinder plays a significant role. When the valve is installed far from the actuator, the air volume in the connecting tube becomes an uncontrolled buffer. This extra volume compresses and expands during operation, weakening the valve’s ability to regulate flow precisely.

Pipe diameter amplifies this effect. Larger diameters increase internal air volume, making speed control less responsive. In practice, even a well-designed Throttle Valve will struggle to deliver stable performance if it is mounted too far from the cylinder or paired with oversized tubing.

In compact automation lines, it is not unusual to see throttle valves mounted on a manifold several hundred millimeters away from the cylinder for convenience. During commissioning, engineers notice inconsistent speeds, particularly at low settings. The instinct is often to suspect air supply instability or valve quality.

In reality, relocating the throttle valve closer to the cylinder—sometimes directly onto the cylinder port—immediately improves speed stability. This practical lesson reinforces that throttle performance is as much about system layout as it is about valve design.

To address space and responsiveness challenges, many modern systems adopt compact or port-mounted throttle valve designs. These units minimize dead volume and shorten the airflow path, allowing finer adjustment and more repeatable settings.

For equipment builders, compact throttle valves simplify integration and reduce assembly time. For distributors and procurement teams, they offer a standardized solution that performs reliably across different machine platforms without extensive reconfiguration.

| Installation Method | Speed Stability | Load Sensitivity | Typical Use |

|---|---|---|---|

| Inlet throttling | Moderate to low | High | Light-load, simple motion |

| Outlet throttling | High | Low | Industrial automation, production lines |

| Remote valve placement | Low | High | Not recommended for precision control |

| Close-coupled valve | High | Low | Compact, high-repeatability systems |

This comparison explains why outlet throttling dominates modern pneumatic design, even though inlet throttling remains technically feasible.

When engineers ask what is a throttle valve really controlling, the answer is not just airflow, but how compressed air behaves inside the actuator. Installing the throttle valve on the wrong side of the cylinder introduces instability that no amount of fine adjustment can fully correct.

By understanding air compressibility, minimizing distance, and favoring outlet throttling, pneumatic systems achieve smoother motion and easier commissioning. In most automation applications, choosing the right throttle valve—and placing it correctly—makes the difference between constant troubleshooting and consistent, repeatable performance.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap